Aluminum alloy bridge stand

An aluminum alloy and bridge technology, applied in electrical components and other directions, can solve problems such as inability to quickly adapt to the changing environment and conditions on site, unreasonable structural design of cable bridges, easy deformation, etc. Conditions, effects that are not easily deformed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

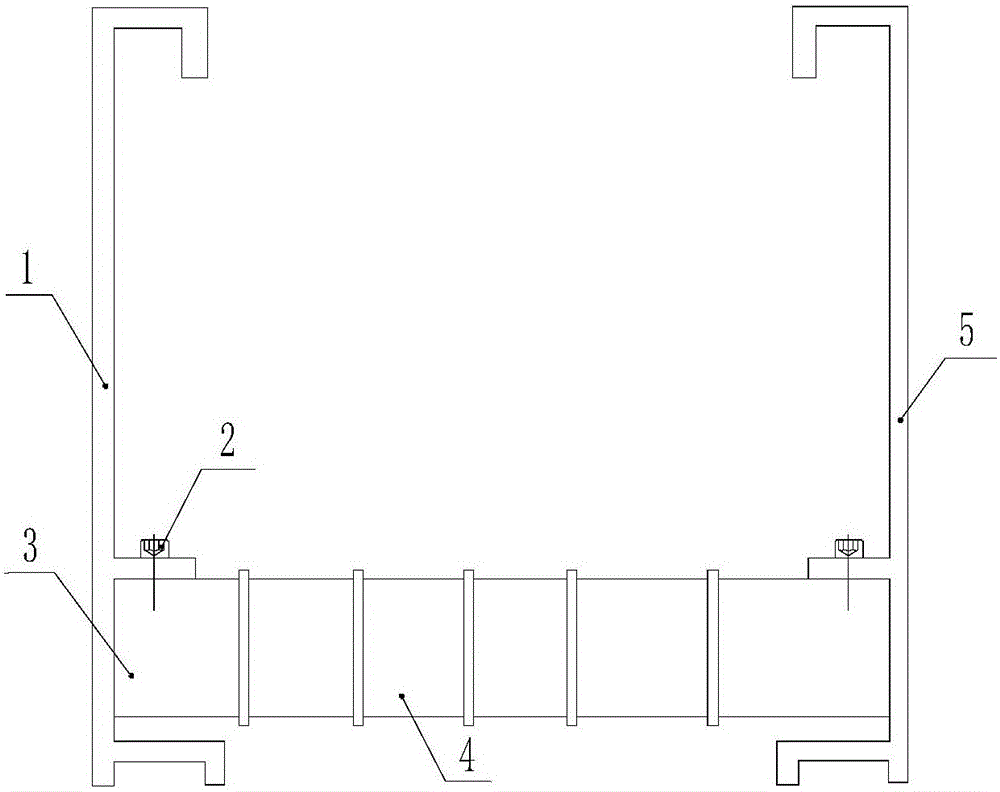

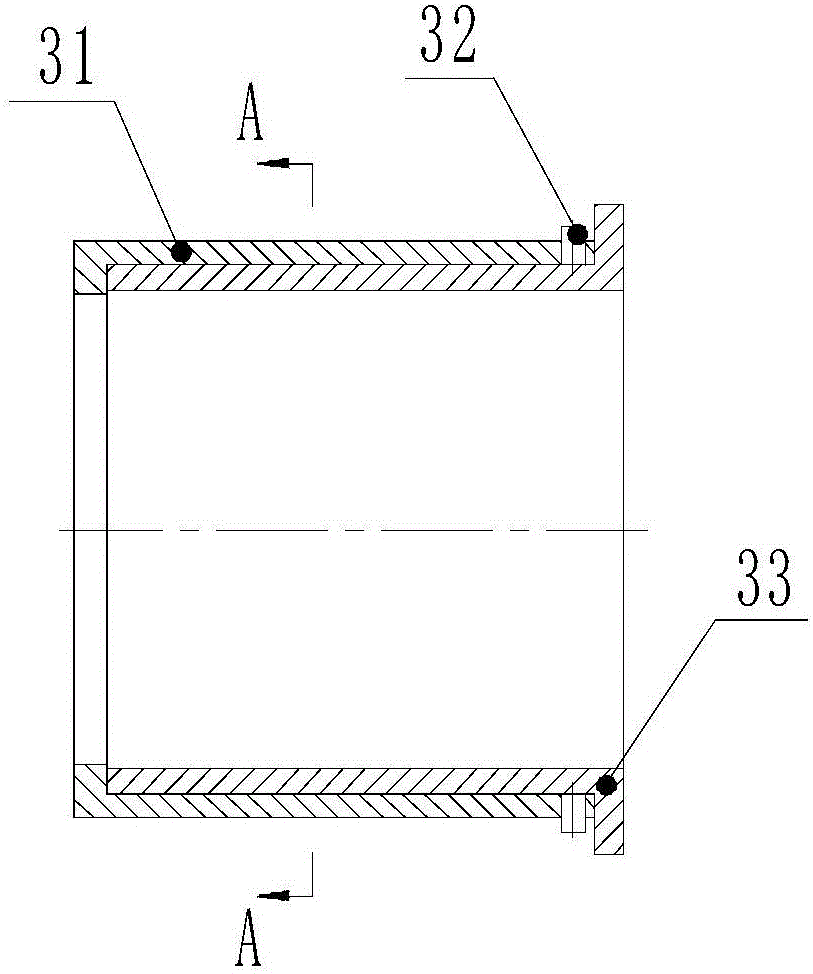

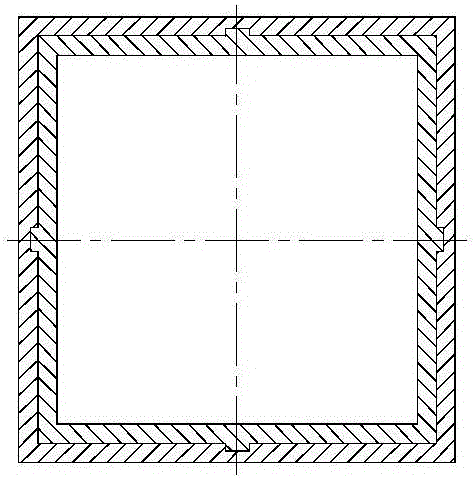

[0018] Examples such as figure 1 , figure 2 , image 3 , Figure 4 and Figure 5 As shown, an aluminum alloy bridge frame includes a left side plate 1, connecting screws 2, two side cross arms 3, a middle cross arm 4 and a right side plate 5; the left side plate 1 and the right side plate 5 are all made of aluminum alloy The materials are extruded by molds, and the cross arms 3 on both sides are installed on the left side plate 1 and the right side plate 5 through connecting screws 2. Composed of an inner cylinder 33, the outer cylinder 31 and the inner cylinder 33 are rectangular structures, the four sides of the inner cylinder 33 are provided with rectangular bosses, and the four sides of the inner wall of the outer cylinder 31 are provided with rectangular grooves , the inner cylinder 33 is installed in the outer cylinder 31 and can move left and right, the four sides of the outer wall of the outer cylinder 31 are provided with installation holes, the limit screw 32 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com