Oscillating head micromotor based on giant magnetostrictive material

A giant magnetostrictive and oscillating head technology, applied in the direction of piezoelectric effect/electrostrictive or magnetostrictive motors, generators/motors, electrical components, etc., can solve the problems of low efficiency and achieve large output displacement, Ease of Miniaturization, Fast Response Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] The oscillating head micromotor based on giant magnetostrictive materials includes a stator, a rotor and a pre-pressure system, specifically as Image 6 shown. The stator of the motor has a variety of structures, not limited to the structure in the figure. The magnetostrictive effect of the giant magnetostrictive material is mainly used to deform the giant magnetostrictive unit, thereby simultaneously exciting the two first-order bending vibration modes of the stator. state, so that the trajectory of the mass point on the driving end surface where the stator and the rotor are in contact is an ellipse, and the stator drives the rotor to rotate through friction.

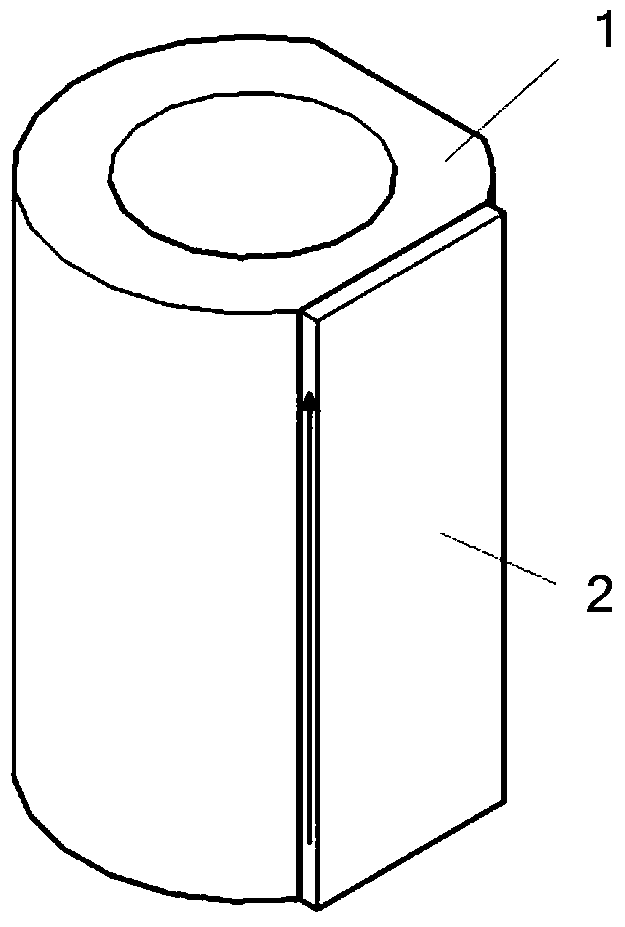

[0049] figure 1 It is a kind of construction method of the stator, which is composed of a magnetically deformable body (giant magnetostrictive material) 2 and a metal base 1 (metal material). Among them, the magnetic deformation body 2 is magnetized along the axial direction. Under the action of an external ma...

Embodiment 2

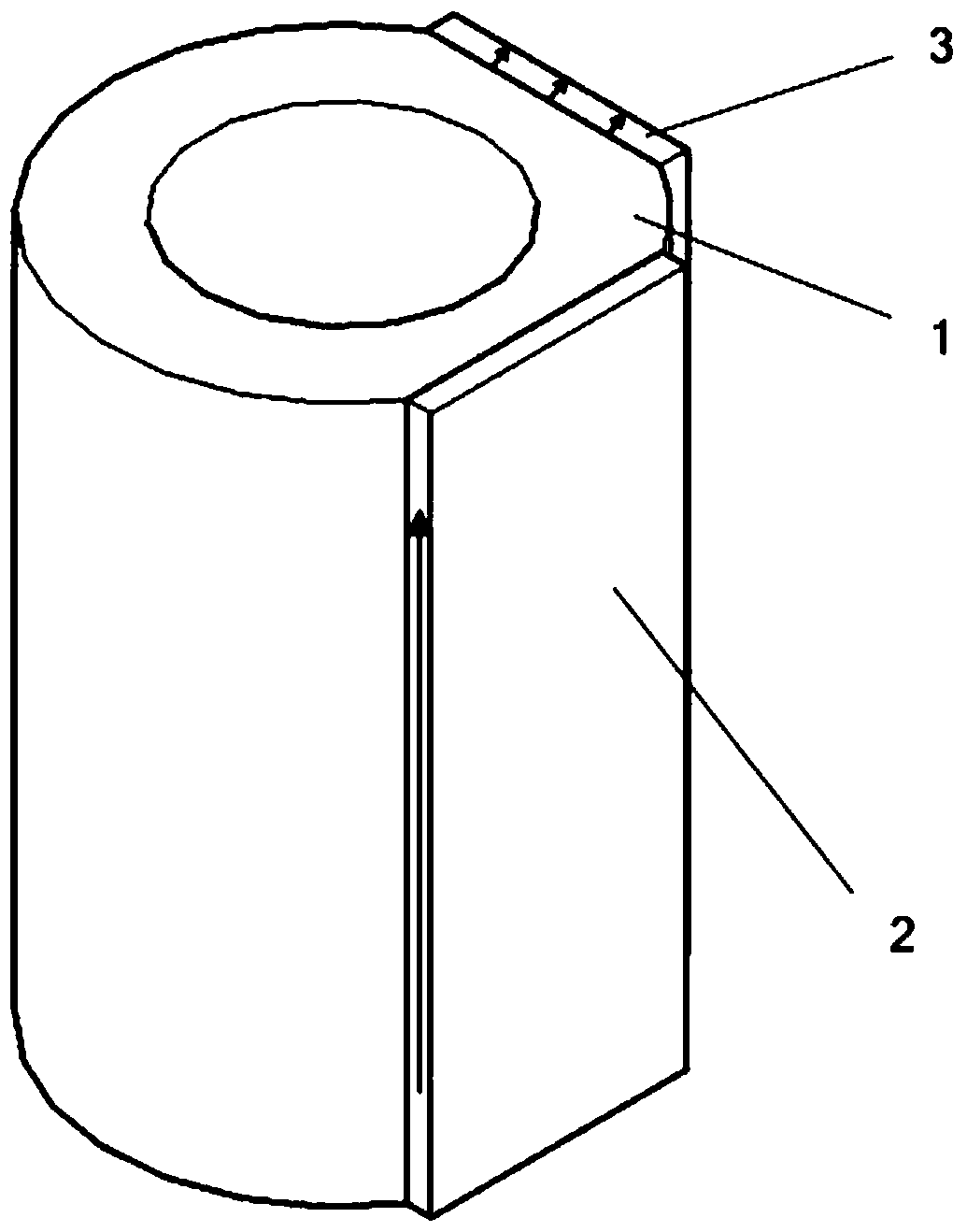

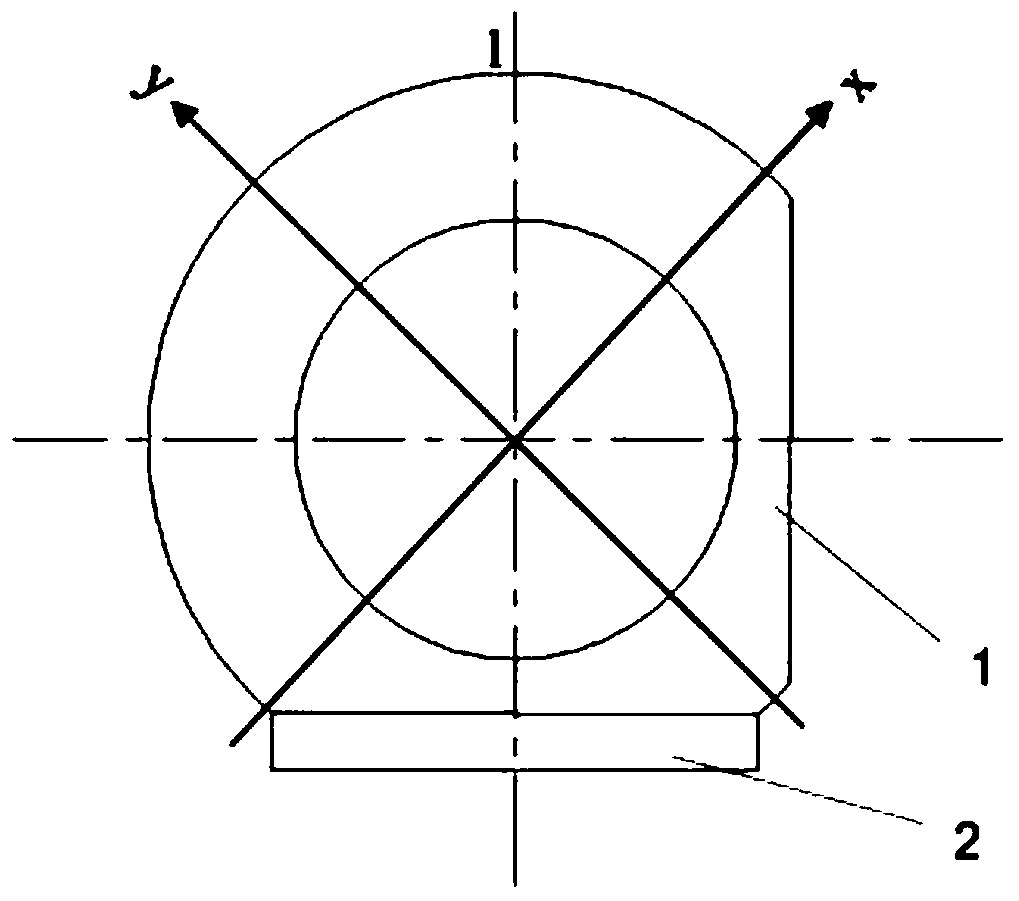

[0058] The micromotor includes a stator, a rotor and a pre-pressure system, specifically as Image 6 As shown, the stator structure is as figure 2 shown. figure 2 Among them, 3 is the piezoelectric material body (piezoelectric material), the direction of the arrow is the polarization direction of the piezoelectric material body, 1 is the metal matrix (metal material), 2 is the magnetically deformable body (giant magnetostrictive material), the direction of the arrow is is the magnetization direction of the magnetically deformable body. Under the action of an external magnetic field, due to the magnetostrictive effect of the giant magnetostrictive material, the stator deforms along the direction 1 ( image 3 shown), so that two first-order bending vibration modes of the stator along the x and y directions can be simultaneously excited. The superposition of the two vibrations forms the bending vibration of the stator cylinder, so that the movement track of the mass point on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com