Active tag module and manufacturing method thereof

A manufacturing method and label technology, which are applied in the manufacture of printed circuits, printed circuits connected with non-printed electrical components, electrical components, etc., can solve the problems of inconvenient hardware design, reduce work efficiency, affect circuit reliability, etc. Simple, improved reliability, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims.

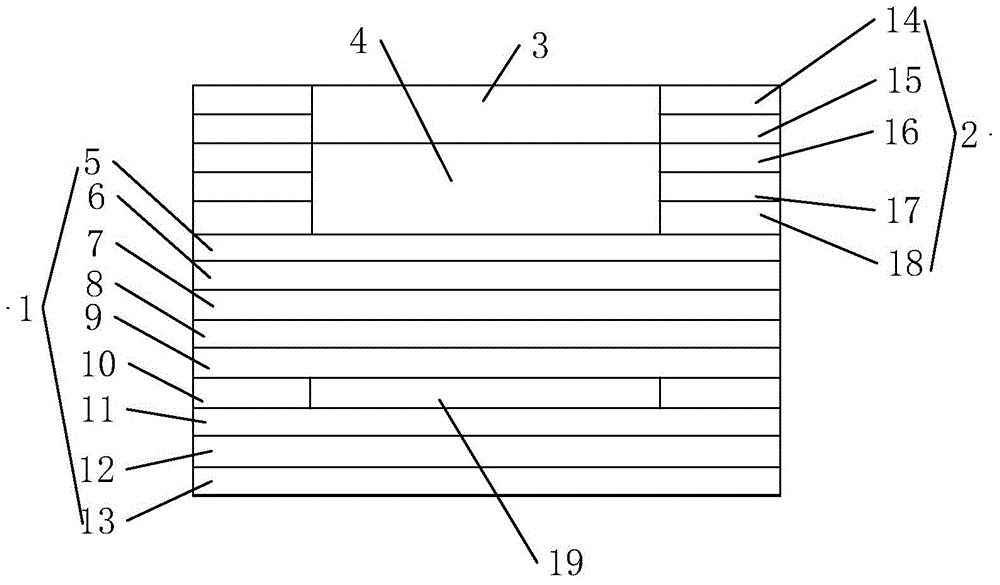

[0015] Please refer to figure 1 , the present invention provides an active label module, including a circuit board 1, an outer frame 2, electronic components and a vinyl layer 3, wherein the outer frame 2 is connected to the upper surface of the circuit board 1, and the outer frame 2 is formed with a through hole 4, the electronic component is located in the through hole 4, and the electronic component is welded on the circuit board 1, the black glue layer 3 is filled in the through hole 4 and is located above the electronic component, and a plurality of external connections are formed on the circuit board 1 pin.

[0016] Due to the adoption of the above technical solution, the present invention can package the chip of the active label and its peri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com