Crankshaft for reciprocating piston engine

一种活塞式发动机、曲轴的技术,应用在曲轴等方向,能够解决困难等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

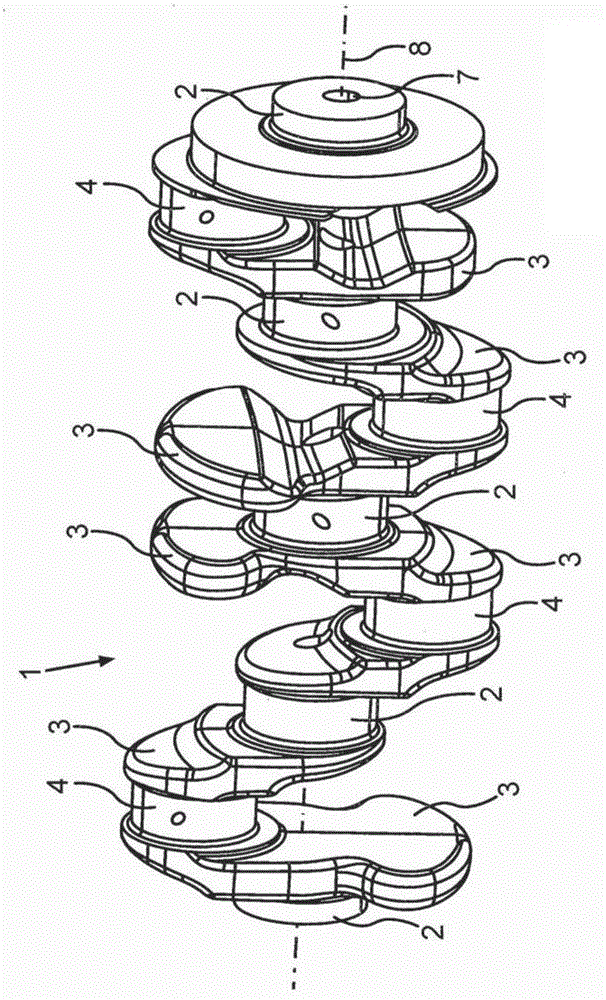

[0016] The crankshaft 1 known from the prior art is shown in a schematic perspective view figure 1 Shown in. It is known that the crankshaft 1 is supported in a crankshaft bearing (not shown here) of a piston engine by means of a corresponding journal 2. The crankshaft 1 basically rotates around a rotation axis 8, which at the same time corresponds to the center line of the through hole 7 of the crankshaft 1. During the rotation of the journal 2 only in its corresponding bearing about the axis of rotation 8 and therefore about its corresponding longitudinal axis, the corresponding connecting rod journal 4 (the connecting rod journal is connected by means of the corresponding crank arm 3 to the journal 2 Connection) basically depicts a circular orbit around the axis of rotation 8. The connecting rod journals 4 are surrounded by corresponding connecting rod bearings of connecting rods not shown here, wherein the number of connecting rod journals 4 is equal to the number of cylin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com