Sand mold recovery equipment

A technology for recycling equipment and sand molds, which is applied to casting molding equipment, metal processing equipment, and machinery for cleaning/processing mold materials, etc. It can solve the problems of large energy consumption by fans, reduced efficiency of iron filings removal, and dust. , to achieve the effect of improving the degree of cleaning, saving management time, and facilitating recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

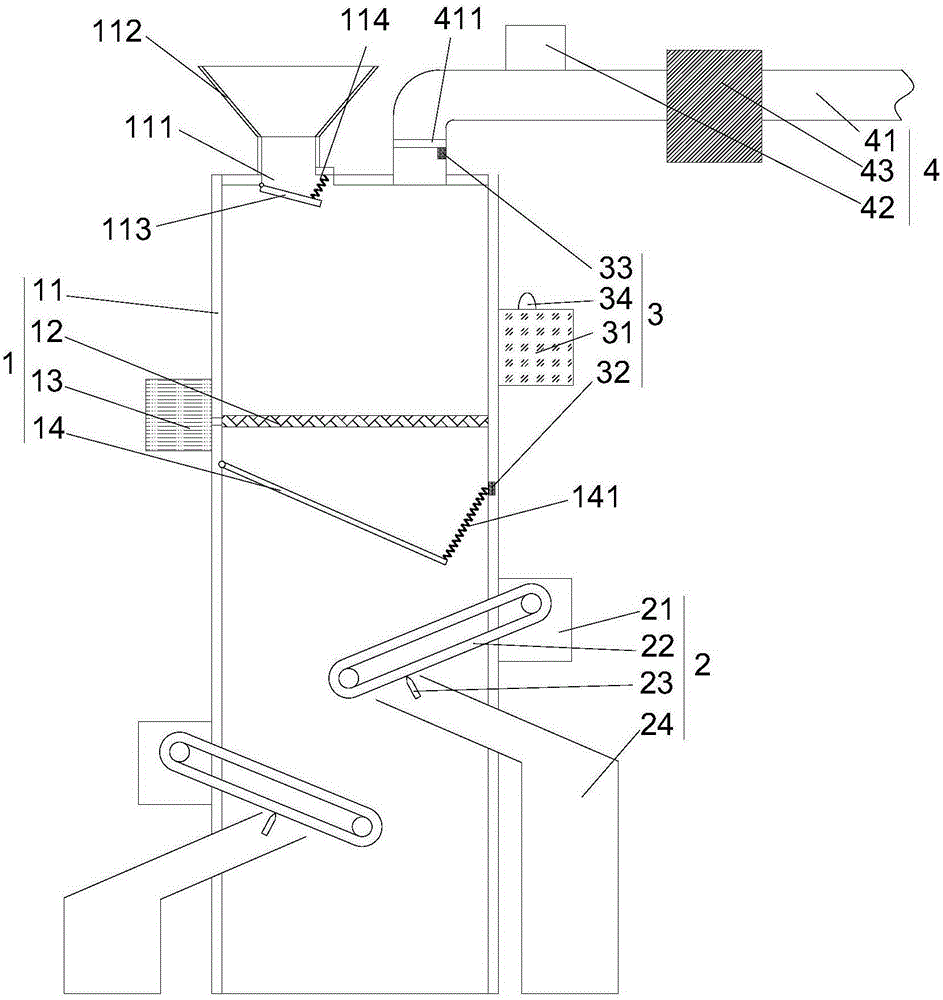

[0019] refer to figure 1 As shown, a kind of sand recovery equipment proposed by the present invention includes a raw sand recovery mechanism 1, a plurality of iron scrap recovery mechanisms 2 and a comprehensive control mechanism 3;

[0020] Raw sand recovery mechanism 1 includes raw sand recovery box 11, filter screen 12, vibrating motor 13 and sand guide plate 14; raw sand recovery box 11 is provided with sand inlet 111, filter screen 12 is installed in the raw sand recovery box 11 and is located The lower end of the sand inlet 111, the vibrating motor 13 is connected with the filter screen, the sand guide plate 14 is installed obliquely in the raw sand recovery box 11, and the end of the sand guide plate 14 located in the inclined direction is movably connected with the inner wall of the raw sand recovery box 11, and the sand guide plate 14 The end away from the inclined direction is connected to the inner wall of the raw sand recovery box 11 by the first spring 141;

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com