A two-mode hybrid transmission

A hybrid power and transmission technology, which is applied in power plants, hybrid vehicles, pneumatic power plants, etc., can solve the problems of low maximum speed and unsuitable for ordinary passenger cars.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

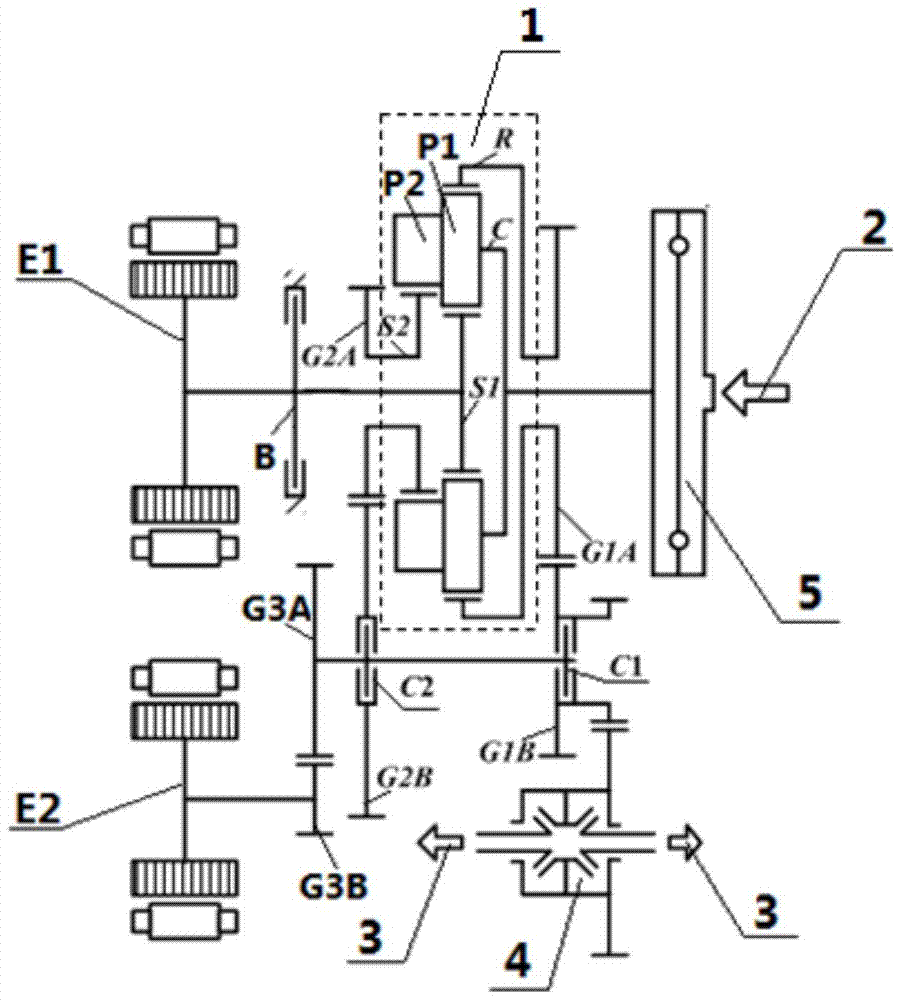

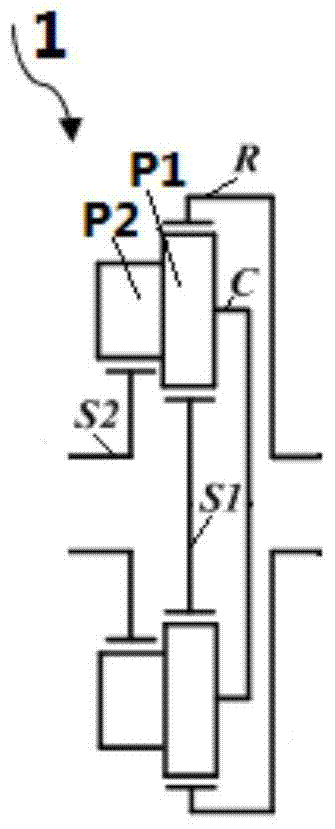

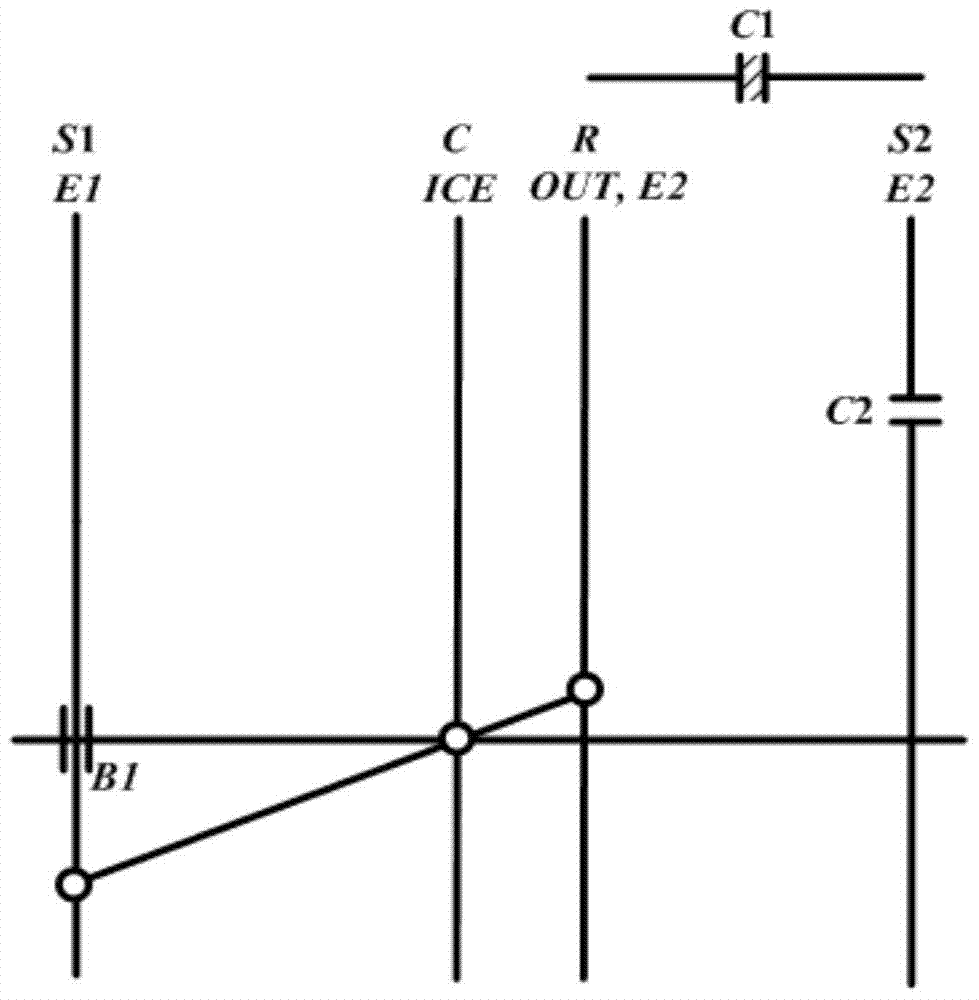

[0026] A two-mode hybrid transmission such as figure 1 As shown, it includes double planetary row 1, first motor E1, second motor E2, first clutch C1, second clutch C2, brake B, input shaft 2, output shaft 3 and differential 4; as figure 2 As shown, the double planet row 1 includes the ring gear R, the planet carrier C, the front planet P1, the rear planet P2, the front sun gear S1 and the rear sun gear S2. The outer diameter of the rear planet P2 is large tooth width and small index circle. The outer diameter of the front sun gear S1 is smaller than that of the rear sun gear S2, and the outer diameter of the front sun gear S1 is about 40mm. The outer diameter of the rear sun gear S2 is about 52mm; the front planet P1 and the rear planet P2 are sequentially installed on the planet carrier C, and the front planet P1 meshes with the front sun gear S1 and the ring gear R respectively to form a front gear The rear planet P2 meshes with the front planet P1 and the rear sun gear S...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com