Electric driving wheel system

An electric drive and power technology, applied in the direction of electric components, electrical components, electromechanical devices, etc., can solve the problems of low torque density, high heat production, poor economy, etc., to reduce frictional heat, increase transfer efficiency, increase economical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

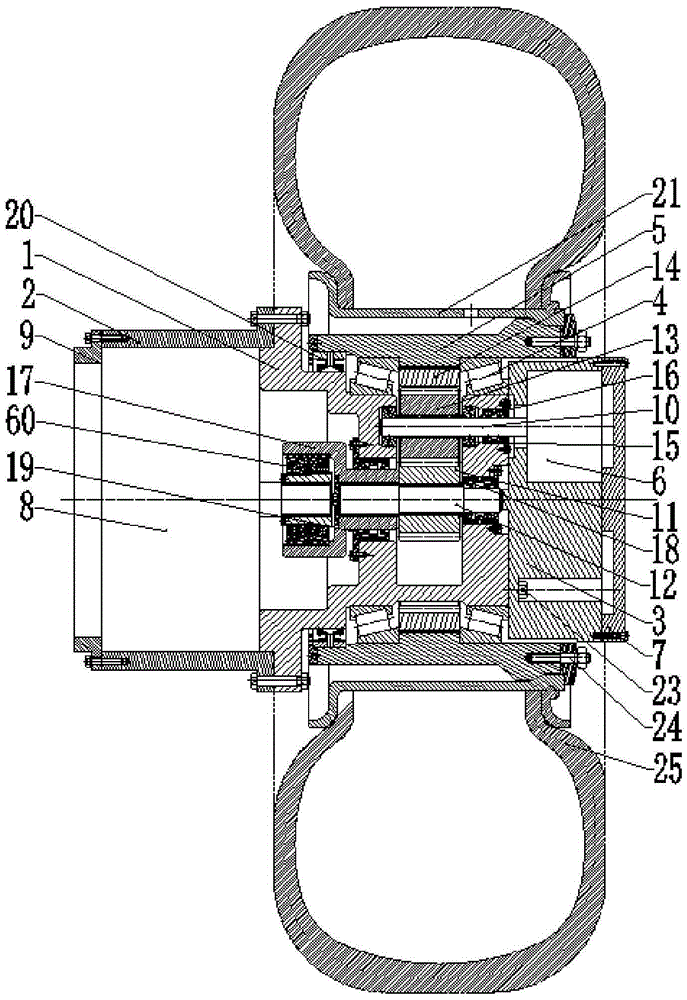

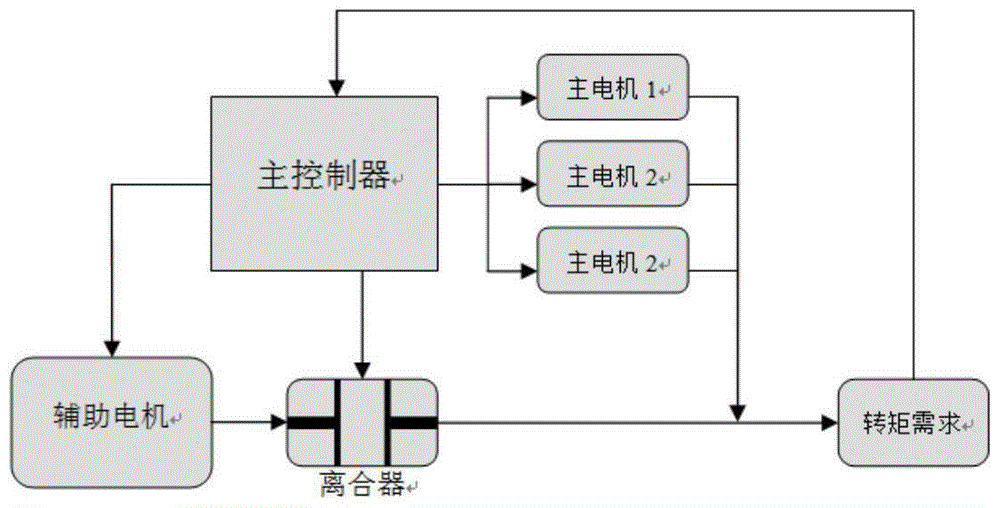

Embodiment 1

[0032] In the electric drive wheel system in this embodiment, at least one planetary gear power input motor provides multi-power source power for the auxiliary motor through at least one planetary gear power input motor, wherein the power transmitted by the auxiliary motor needs to be adjusted by the power The components are adjusted to match the power of the main motor and transmitted to the power coupled transmission components. The power coupling transmission assembly adopts a single-stage planetary gear row for power transmission, proportional conversion and coupling output. That is to say, multiple planetary gear power input motors are used as the main motor unit, and the power output is directly transmitted to the planetary gears, and then output to the hub after deceleration and torque increase of the planetary gears and ring gears; the sun gear power input motors are used as auxiliary motors It is a large-power motor, and its power output is adjusted by the power adjus...

Embodiment 2

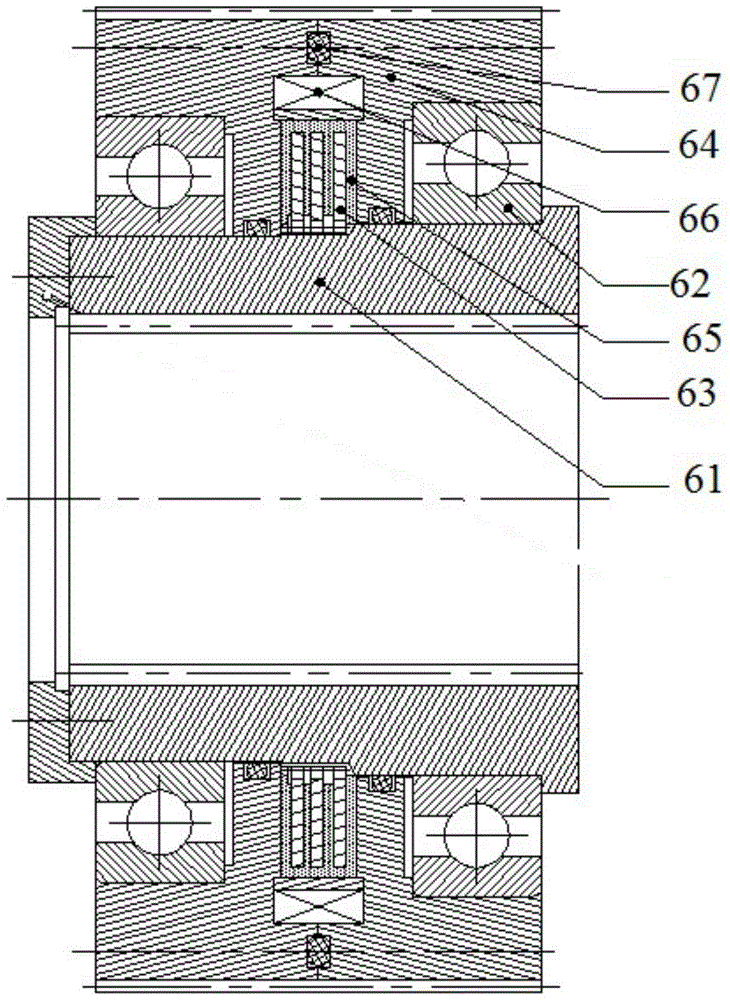

[0068] In this implementation, a harmonic gear is used to replace the power coupling assembly in Embodiment 1, that is, the structure of the planetary gear. The harmonic gear mainly includes a power generator, a flex spline and a steel wheel. When using the harmonic gear to replace the structure in Example 1, there is only one main motor in the structure, which is directly connected to the steel wheel. The auxiliary motor is connected to the steel wheel through a magneto-rheological clutch. The power generator is connected. The power of the main motor is directly transmitted, and the power of the auxiliary motor is output after the adjustment of the clutch and the deceleration and torque increase of the flex spline and steel wheel. Under the condition of low torque demand, the main motor works alone. Under the condition of high torque demand, the main and auxiliary motors work together to provide coupling power, and the power coupling is completed at the joint of the flex spli...

Embodiment 3

[0070] In this embodiment, active gears are used to replace the power coupling assembly in Embodiment 1, that is, the planetary gear structure. The active gear mainly includes a shock wave device, a live gear, and a center wheel, which are similar to the harmonic gear. When replacing the inventive mechanism in Embodiment 1, there is one main motor, which is directly connected to the center wheel, and the auxiliary motor passes through the magneto-rheological The clutch is connected to the shock. The main motor directly drives the center wheel to rotate for power transmission; the auxiliary motor drives the shock wave to rotate through the adjustment of the clutch, and the power output is performed after the live gear and the center wheel decelerate and increase torque. Under the condition of low torque demand, the main motor works alone. Under the condition of high torque demand, the main motor and auxiliary motor work together to provide coupling power. The power coupling is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com