Synchronous head sheave balance adjustment method for multi-rope winding type elevator

A balance adjustment and winding technology, which is applied in hoists, lifting equipment in mines, transportation and packaging, etc., can solve the problems that cannot meet the requirements of multi-rope winding hoist wire rope tension balance and synchronization, and reduce the payload at the end of the wire rope.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

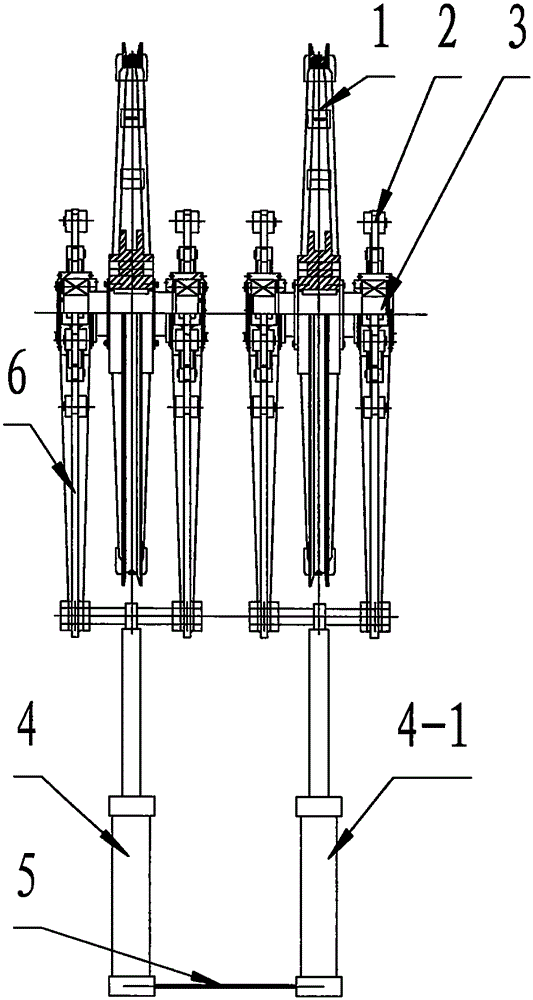

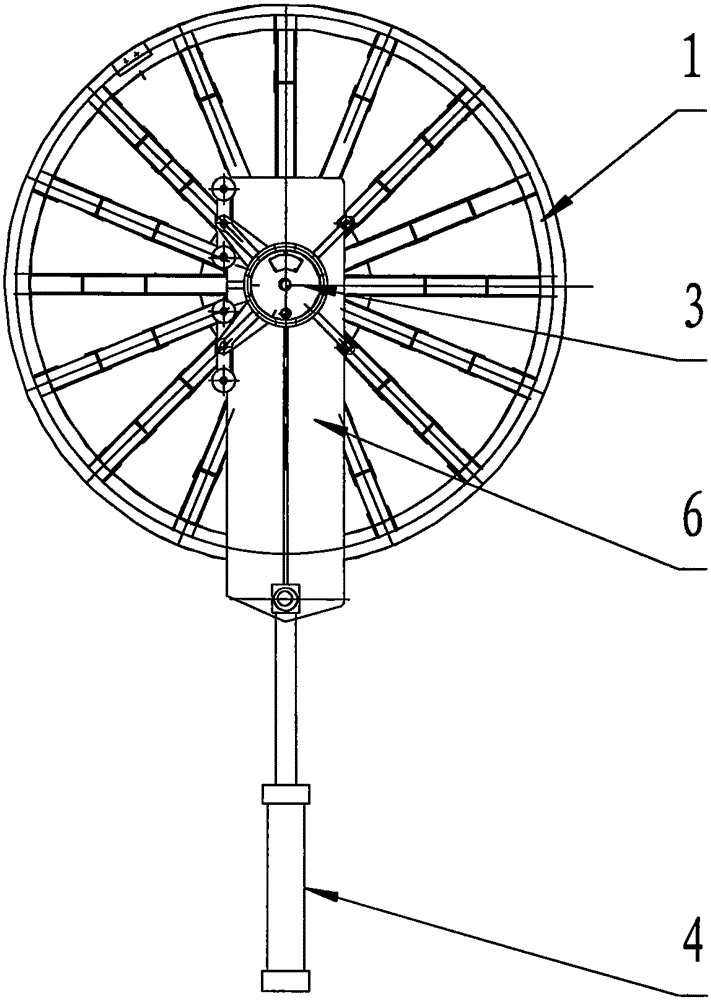

[0028] A second hydraulic cylinder 4-1 is arranged symmetrically on one side of the first hydraulic cylinder 4, and a communication device 5 is arranged between the bottoms of the two hydraulic cylinders; a bearing bracket 6 is respectively arranged above the cylinder rods of the first hydraulic cylinder 4 and the second hydraulic cylinder 4-1 , the bearing bracket 6 is coaxially provided with two support plates, the two support plates are arranged symmetrically, the sky wheel body 1 is arranged between the two support plates, the sky wheel bearing 2 is arranged correspondingly in the middle of the support plate, and the sky wheel shaft 3 is arranged in the sky wheel bearing 2 ; When the multi-rope winding hoist is working, two steel wire ropes pass through the sky wheel body 1 to lift the container. When the container is in the lifting operation, when the steel wire rope wound by the sky wheel on the hydraulic cylinder 4 is stressed, the sky wheel body 1. The first hydraulic c...

Embodiment 2

[0030] When the other wire rope is stressed, the sky wheel body 1 is compressed downward by the second hydraulic cylinder 4-1 to reduce the stress and at the same time relax the wire rope, and the wire rope is relaxed to balance the force with the other side of the wire rope adjustment.

Embodiment 3

[0032] When the force on the two sky wheel bodies 1 is unbalanced, pressure compensation is generated for the hydraulic cylinder: when the first hydraulic cylinder 4 is compressed, the hydraulic pressure pressurizes the second hydraulic cylinder 4-1 through the communication device 5, and the pressurization makes the first hydraulic cylinder 4. Balance the pressure with the second hydraulic cylinder 4-1. When the first hydraulic cylinder 4 is compressed, the hydraulic pressure pressurizes the second hydraulic cylinder 4-1 through the communication device 5. After the pressurization, the second hydraulic cylinder 4-1 and the first hydraulic cylinder A hydraulic cylinder 4 is pressure balanced.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com