A foamy crude oil three-phase separator

A technology of three-phase separator and separator, which is applied in the direction of refining by centrifugal force, refining by heating/cooling, dehydration/demulsification by mechanical method, etc. It can solve the problems such as poor three-phase separation effect of foaming crude oil, and achieve improvement Dehydration efficiency of crude oil, improvement of separation degree, effect of increasing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0062] The invention provides a foamy crude oil three-phase separator to solve the technical problem in the prior art that the three-phase separation effect of the foamy crude oil is not good.

[0063] The technical solution in the embodiment of the present application is to solve the above-mentioned technical problems, and the general idea is as follows:

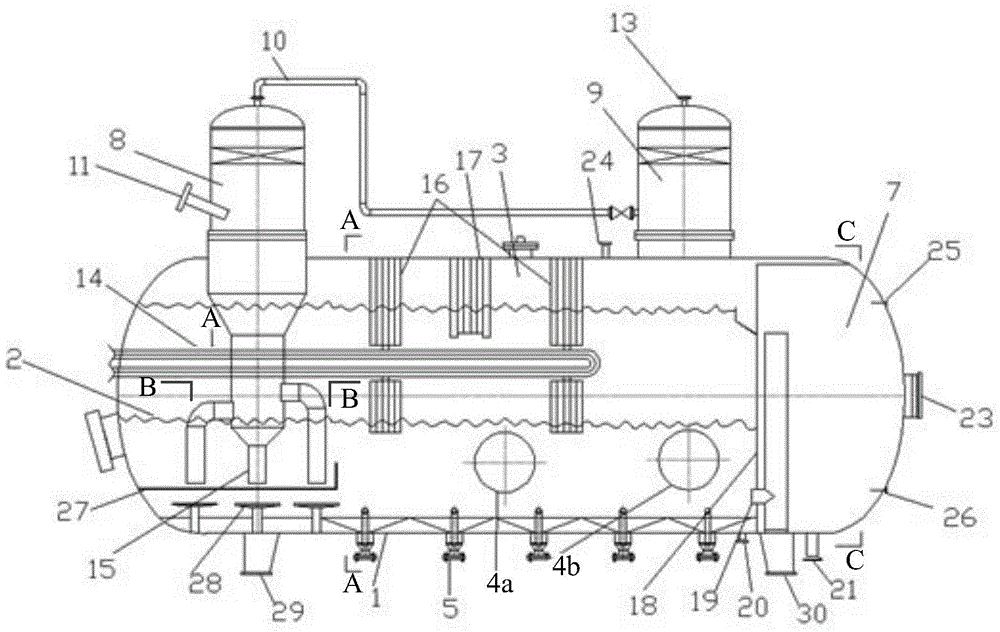

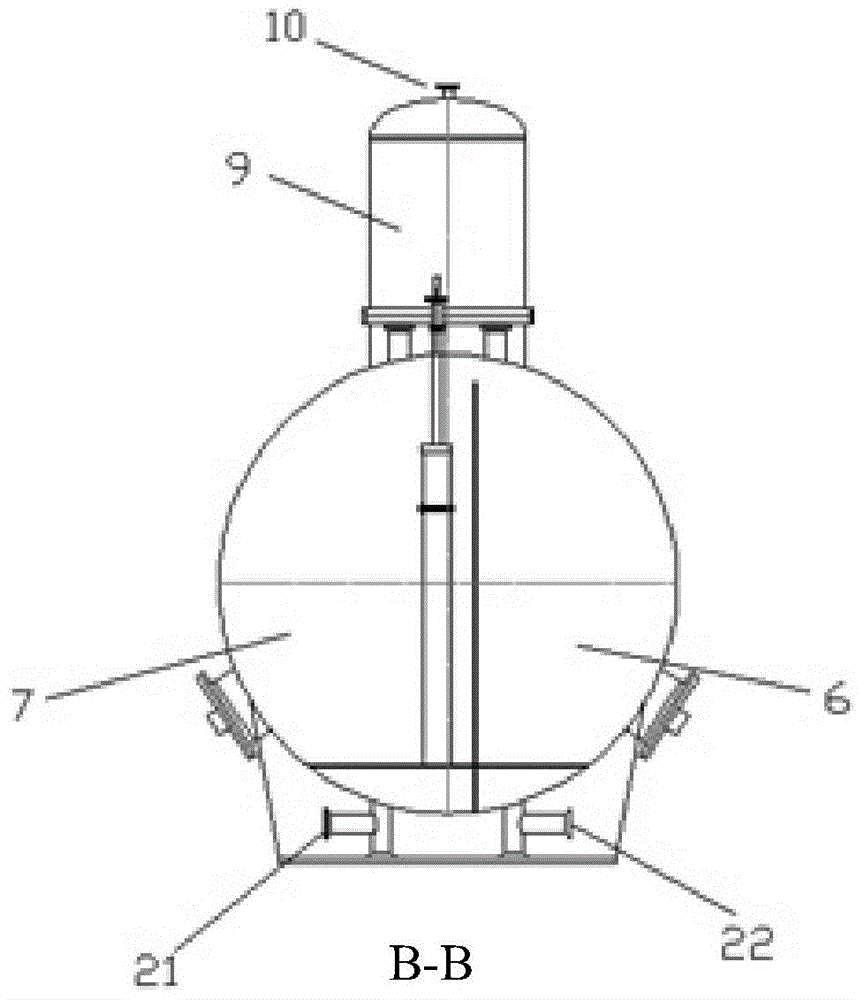

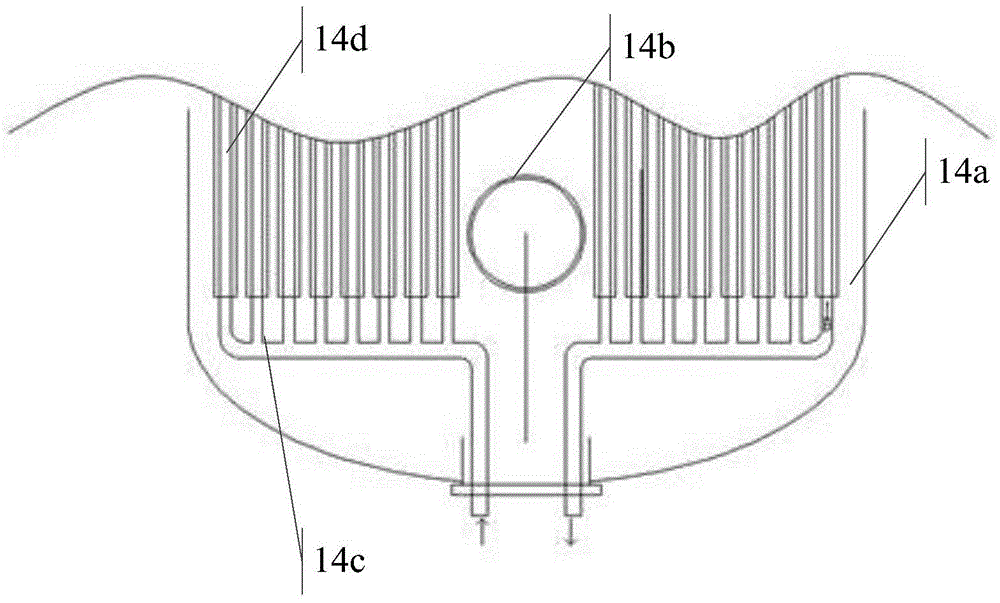

[0064] A foam crude oil three-phase separator is provided, comprising: a tank body; a first support arranged on the first side of the bottom of the tank body; a second support arranged on the second side of the bottom of the tank body, the The first side is opposite to the second side; five sand collection buckets are arranged horizontally between the first support and the second support, and the five sand collection buckets are welded to the tank body and extend into the inside of the tank body; the partition is longitudinally arranged inside the tank body, and divides the tank body into a first tank body space and a secon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com