Mud pump piston with pits on surface

A mud pump and pit technology, which is applied to the components of the pumping device for elastic fluids, pump components, variable displacement pump components, etc., can solve the problems of piston sealing performance decline, piston wear, piston failure, etc. The effect of improving sealing performance, improving wear resistance and extending piston life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The specific content and implementation mode of the present invention will be further described below in conjunction with the accompanying drawings.

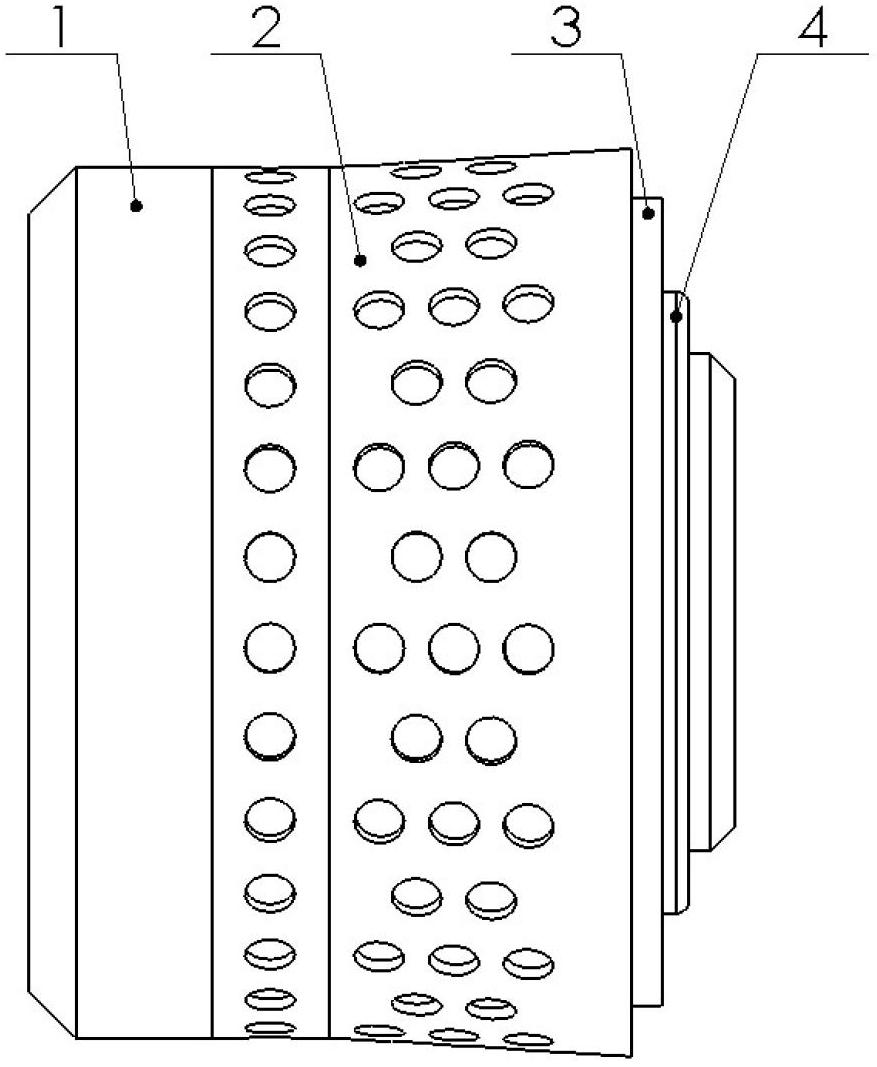

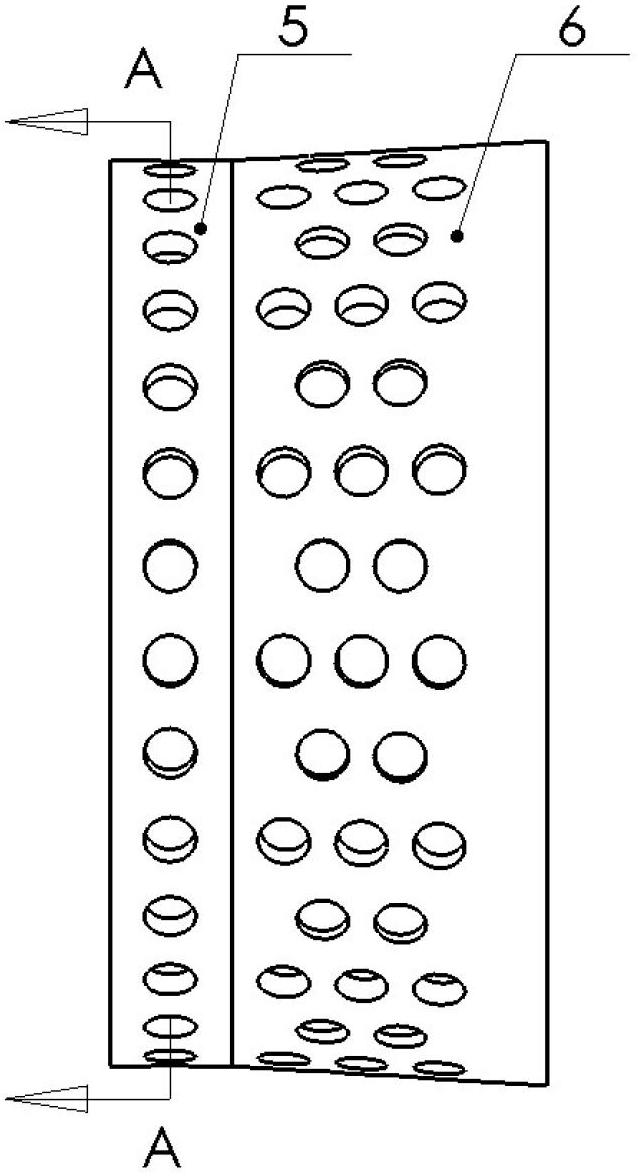

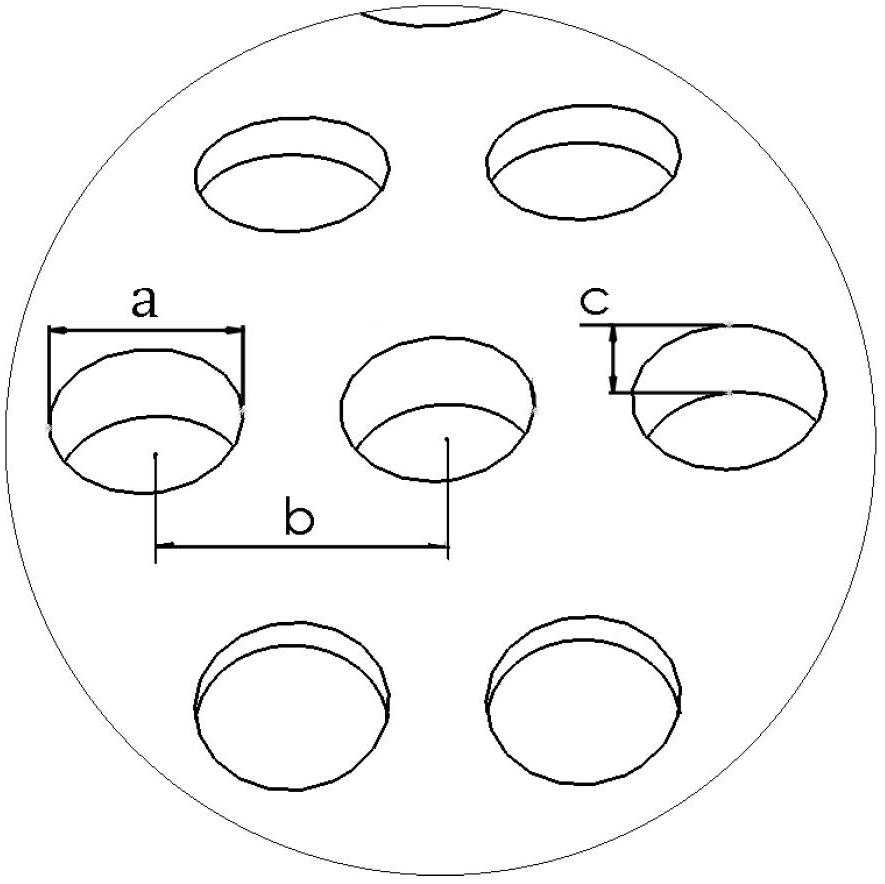

[0024] A mud pump piston with pits on the surface is composed of a piston core 1, a leather cup 2, a pressure plate 3, and a snap ring 4, wherein the leather cup 2 is composed of a nylon mulch ring 5 and a lip rubber 6 bonded together. The leather cup 2 is fixed on the piston core 1 through the pressure plate 3 and the snap ring 4 . The surface of the piston cup 2 of the mud pump has a pit array, and the area of the pit array accounts for 10% to 25% of the surface area of the piston cup 2. The longitudinal section of the pit can be rectangular or arc-shaped. The pit array on the surface of the cup 2 can be formed by one-time die-casting, or can be prepared by reprocessing on the surface of the cup.

[0025] The dimple diameter a, spacing b, and depth c on the surface of the cup are determined according to the size of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com