Synthetic fire-resistant hydraulic oil and preparation method thereof

A technology of hydraulic oil and main components, applied in the field of synthetic fire-resistant hydraulic oil and its preparation, can solve the problems of high ash content, low degradation rate, environmental pollution, etc. The effect of the oil change cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

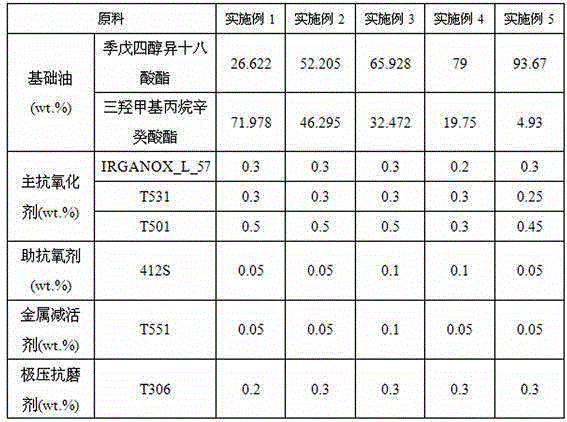

Examples

preparation Embodiment 6

[0027]Preparation Example 6: Add 3kg of IRGANOX_L_57, 3kg of T531, 5kg of T501, 0.5kg of 412S, 0.5kg of T551 and 2kg of T306 into 720kg of Priolube3970, stir at room temperature for 90min, and then add 266kg of pentaerythritol isostearyl Ester, stirred for 30 minutes, sampled for testing, filtered and loaded into barrels after passing the test.

preparation Embodiment 7

[0028] Preparation Example 7: Add 3kg of IRGANOX_L_57, 3kg of T531, 5kg of T501, 0.5kg of 412S, 0.5kg of T551 and 3kg of T306 into 522kg of Priolube3970, stir at room temperature for 120min, and then add 463kg of pentaerythritol isostearyl Ester, stirred for 20 minutes, sampled and tested, filtered and loaded into barrels after passing the test.

preparation Embodiment 8

[0029] Preparation Example 8: Add 3kg of IRGANOX_L_57, 3kg of T531, 5kg of T501, 1kg of 412S, 1kg of T551 and 3kg of T306 into 325kg of Priolube3970, stir at room temperature for 120min, and then add 659kg of pentaerythritol isostearate , stirred for 60 minutes, sampled and tested, filtered and loaded into barrels after passing the test.

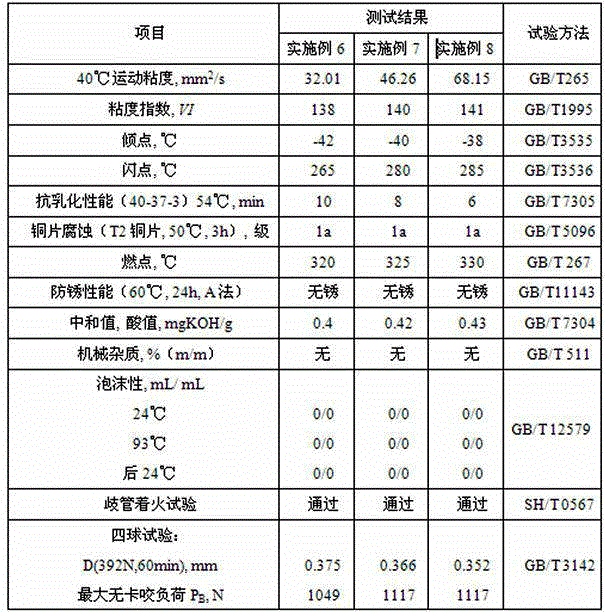

[0030] Table 2 Test parameters of synthetic fire-resistant hydraulic oil

[0031]

[0032] In summary, the fire-resistant hydraulic oil of the present invention has a simple preparation method, is easy to industrialize, has good performance, and has a wide range of applications.

[0033] The invention discloses a synthetic fire-resistant hydraulic oil and a preparation method thereof, belonging to the technical field of hydraulic oil. The technical solution adopted is that a synthetic fire-resistant hydraulic oil comprises the following raw materials in mass percentage: 98.3-98.8wt. % of saturated polyol ester base oil, 1.2-1.7wt.% of ad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com