Micro-arc oxidation hanger

A technology of micro-arc oxidation and hanging rod, applied in the direction of anodizing, electrolysis process, electrolysis components, etc., can solve the problems of destroying the integrity of parts, and achieve the effect of simple installation and disassembly, prolonging service life and improving quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

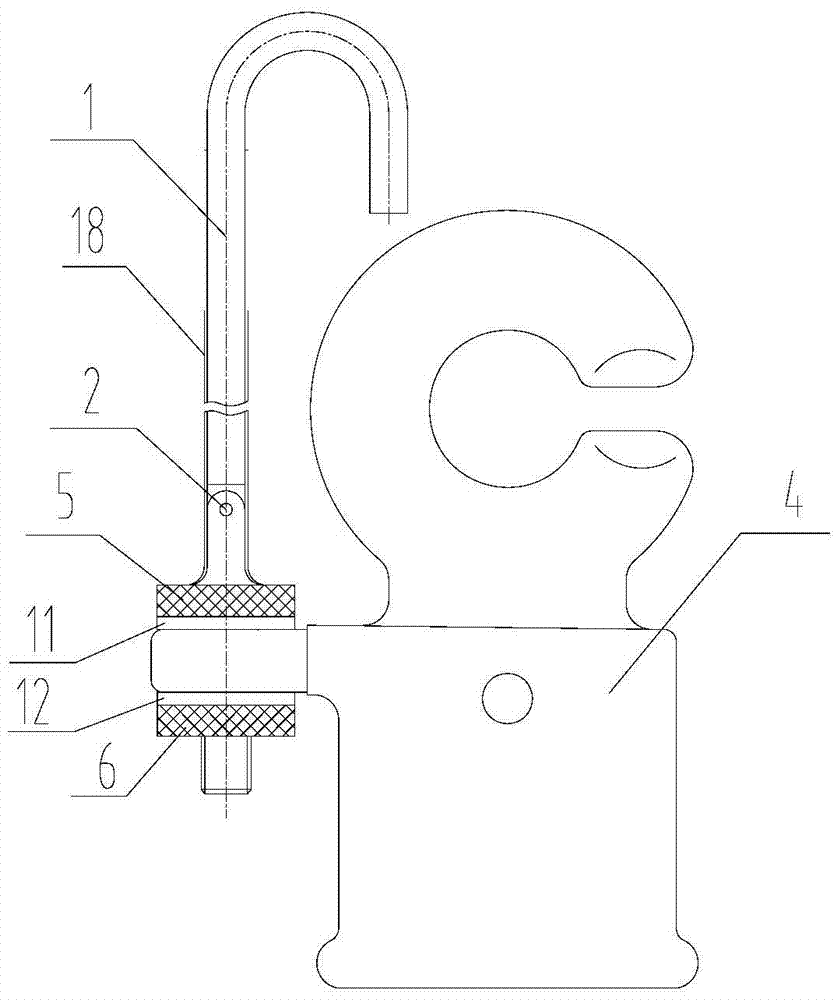

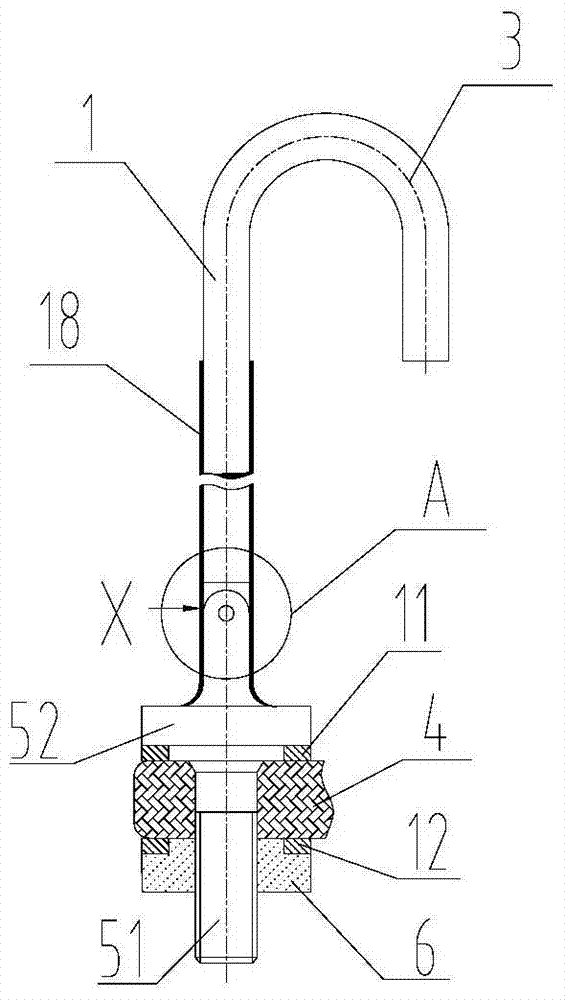

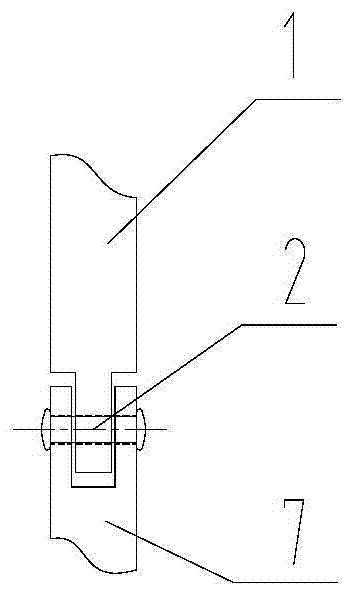

[0027] The present invention will be described in detail in conjunction with accompanying drawing now. This figure is a simplified schematic diagram only illustrating the basic structure of the present invention in a schematic manner, so it only shows the components relevant to the present invention.

[0028] Such as Figure 1-10 As shown, a micro-arc oxidation hanger of the present invention includes a hanging rod 1, a clamping mechanism located at the bottom of the hanging rod 1 and a pin shaft 2 for rotatingly connecting the hanging rod 1 and the clamping mechanism, and the top of the hanging rod 1 A hook 3 is provided, and the hook 3 is used to hang the aluminum alloy parts 4 that need to be micro-arc oxidized and immersed in the electrolyte.

[0029] Wherein, the clamping mechanism includes a bolt 5 and a nut 6, the bolt 5 includes a screw rod 51 and a head 52 arranged at one end of the screw rod 51, the screw rod 51 between the head 52 and the nut 6 is covered with a mi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com