Integrated construction technology of adjustable tie beam and pier column and special formwork for construction

An adjustable, formwork technology, applied in the direction of formwork/formwork/work frame, bridge, bridge parts, etc., can solve the problems of reduced connection between tie beam and pier column, reduced construction progress, increased cost, etc., to save material leasing cost, enhance the integrity, enhance the effect of generality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given hereby, and the details are as follows:

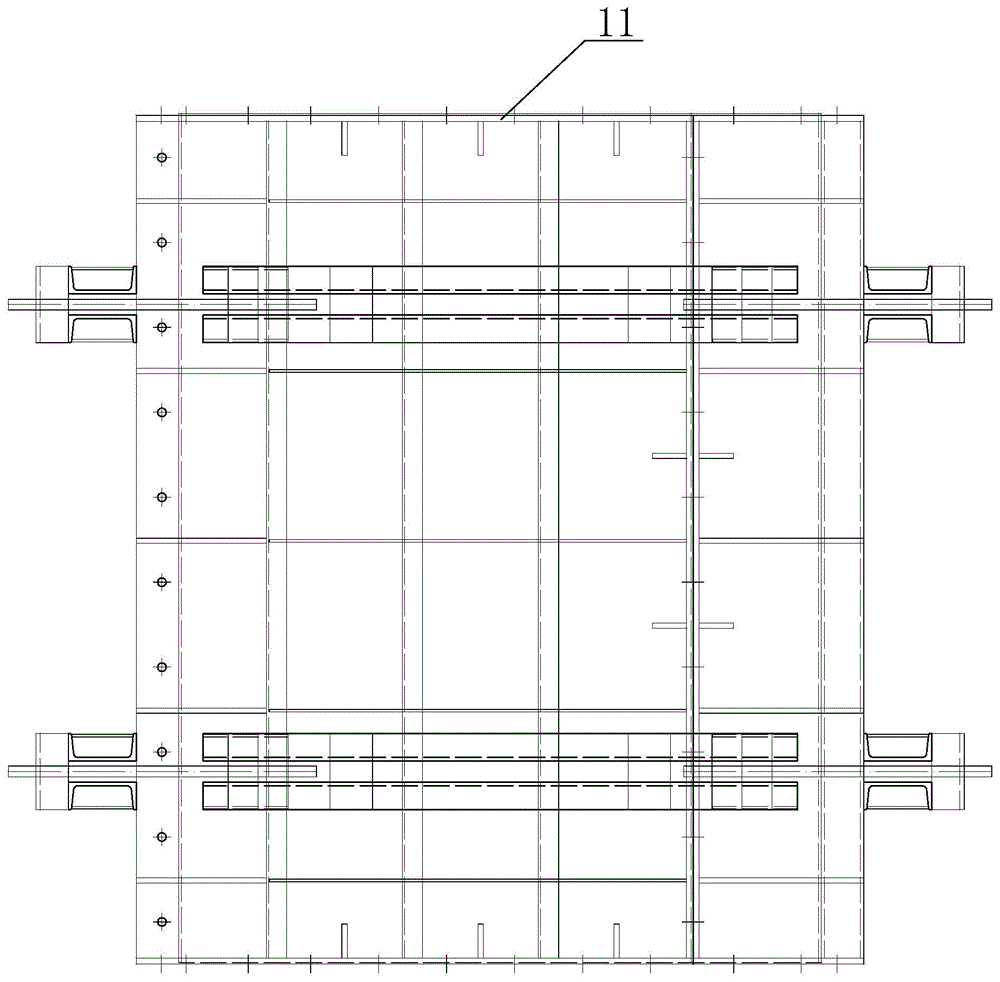

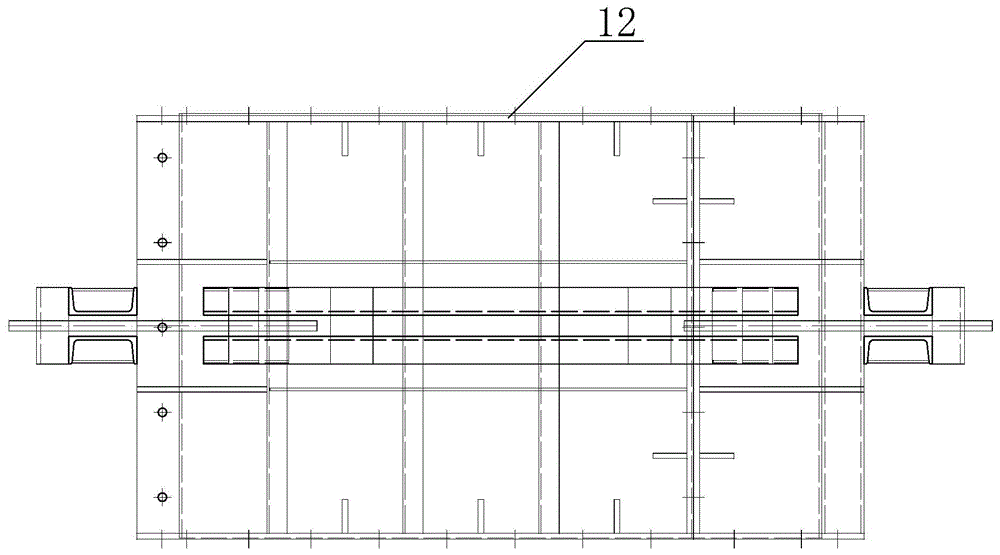

[0045] Such as Figure 1a , 1b as shown,

[0046] The special template for the integrated construction of adjustable tie beam and pier column includes pier column formwork, and the integrated structure of pier column formwork also includes connection formwork and tie beam formwork. The top of the pier column formwork is provided with an upper connection plate 11, and the lower connection plate of the connection formwork is connected with the upper connection plate 11 of the pier column formwork by bolts.

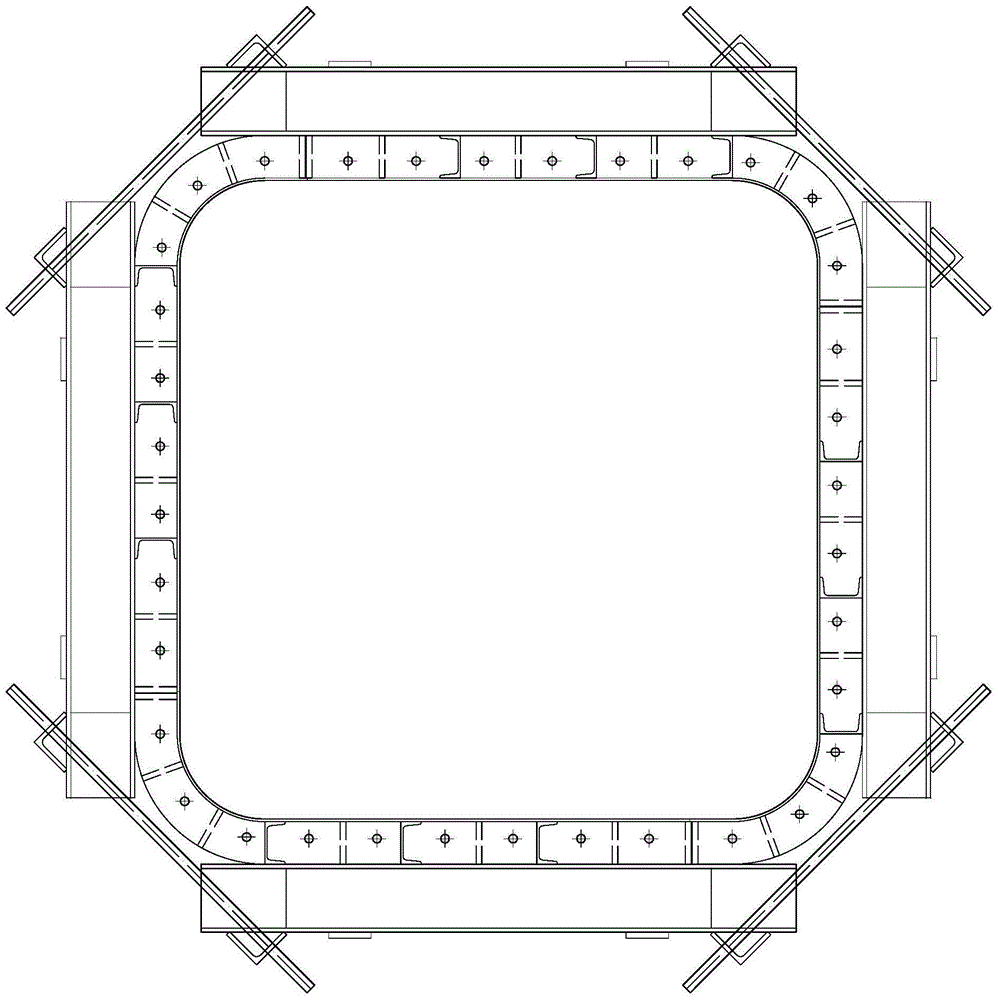

[0047] Such as Figure 3a , 3b As shown, the connection template is sequentially connected by the C module 5, the A module 3, and the B module 4 to form a C-shaped top view. The opening direction of the C-shaped is facing forward. The side end plates of the first module on the side end ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com