Spray-sowing slope protection structure for steep rock side slope

A technology of spray-mixed vegetation on rocky slopes, applied in infrastructure engineering, botanical equipment and methods, horticulture, etc., can solve the application limitations of spray-mixed vegetation technology, reach 1:0.3, and it is difficult to cover steep slopes First-class problems, to achieve the effect of preventing dangerous rocks from falling, increasing the coefficient of friction, and stabilizing the slope

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

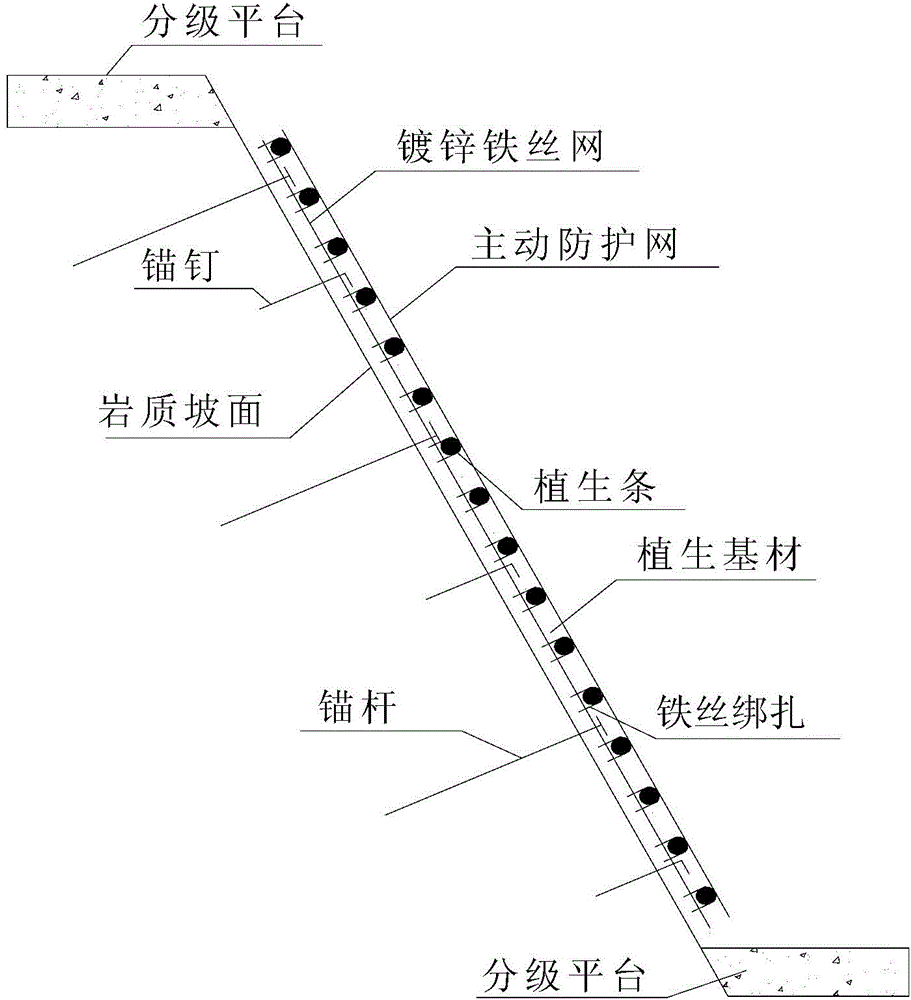

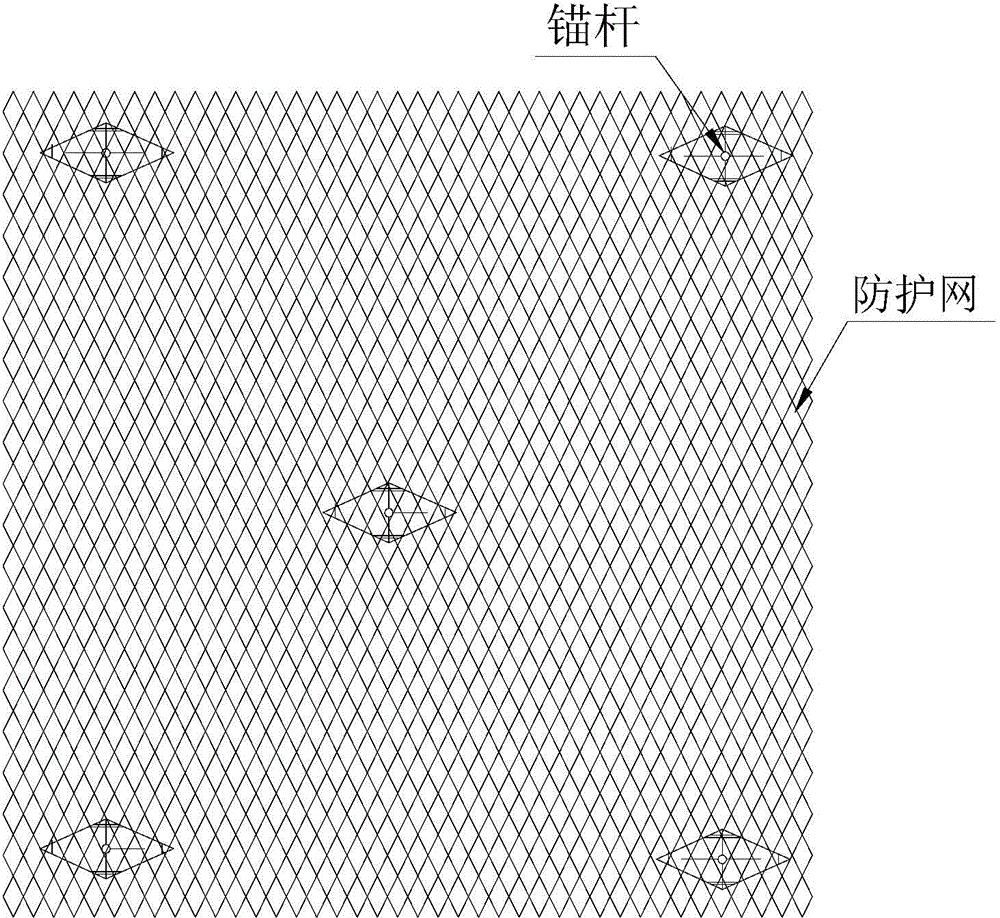

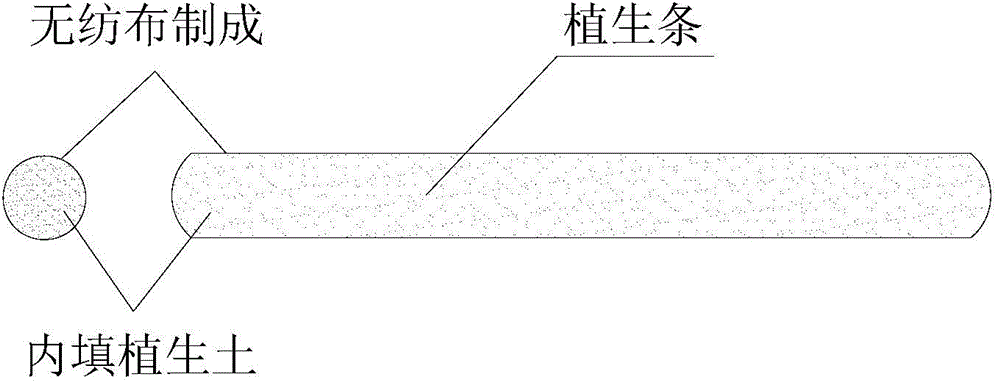

[0023] Below in conjunction with accompanying drawing, the technical scheme of the present invention will be further described, Figure 1~3 The basic composition of the slope protection structure involved in the present invention and the structures of the active protection net and the vegetation strip are shown now.

[0024] As shown in the figure, the spray-mixed vegetation slope protection structure of the present invention for steep rock slopes is arranged on the slope between the graded platforms of rock slopes, and is composed of galvanized wire mesh, vegetation strips, active protection nets, and anchor rods. The support and reinforcement components formed by the slope and the subsequent sprayed vegetation base material.

[0025] The support and reinforcement components include galvanized barbed wire, vegetation strips, active protection nets, and anchor rods. The galvanized wire mesh is spread and hung on the slope surface and fixed with anchors. The mesh size of the g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com