Pushing and supporting device of tunneling machine and construction method

A tunnel boring machine and support device technology, which is applied in tunnels, earthwork drilling, mining equipment, etc., can solve the problems that the strength cannot bear the thrust of 250 tons, and the embedding accuracy of embedded parts is not high, so as to avoid uneven force and step The effect of smooth, safe, reliable and high-precision installation of embedded parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

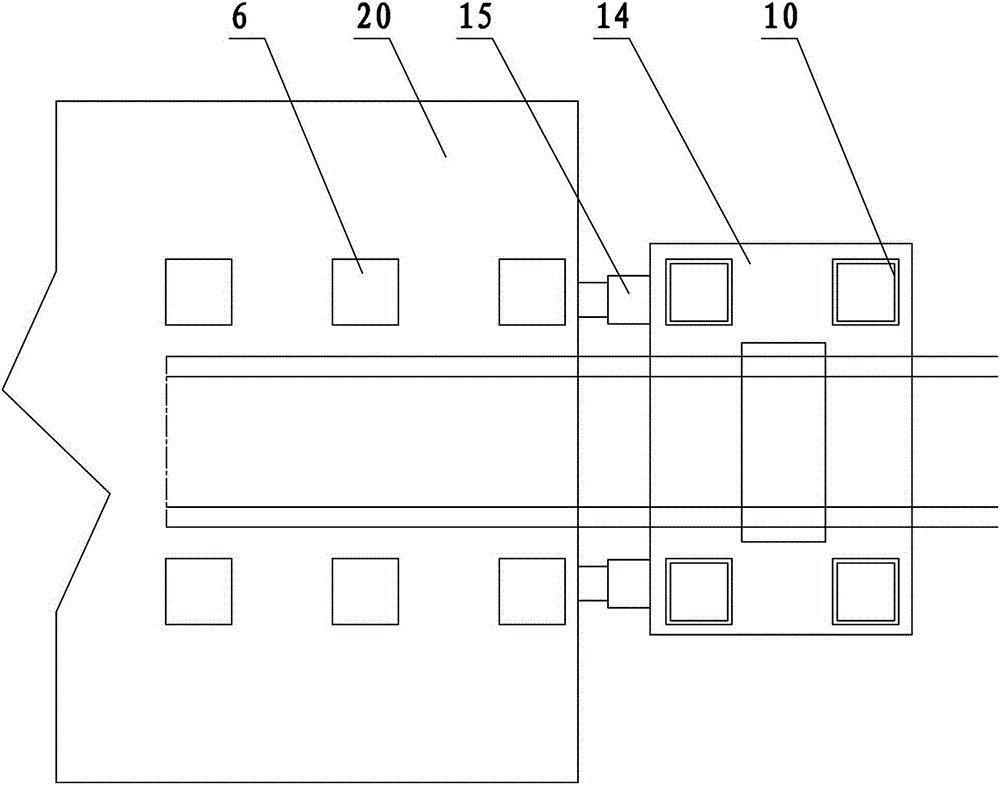

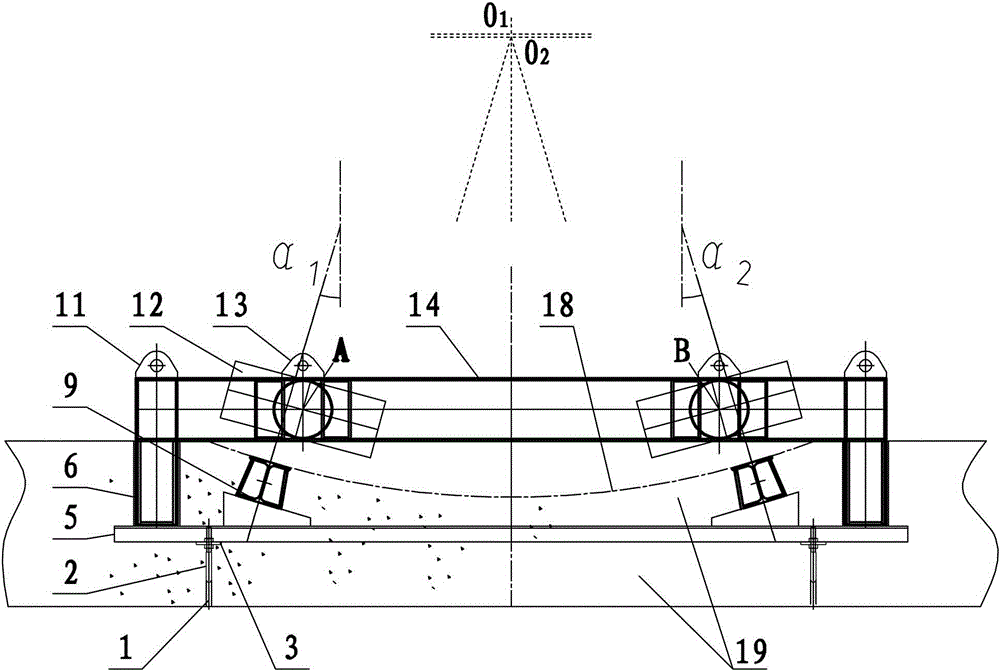

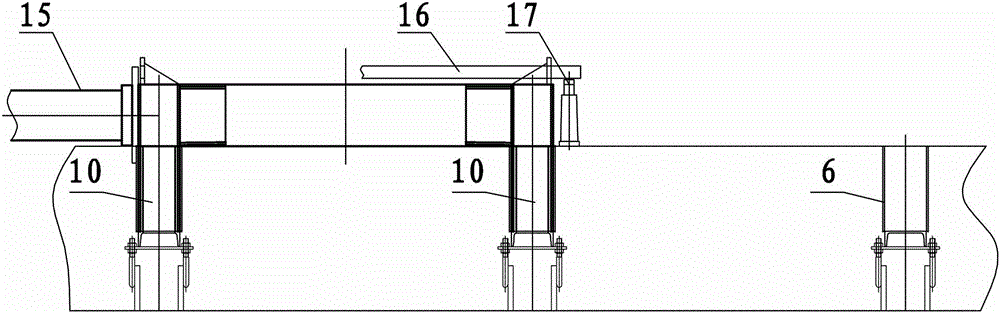

[0037] Such as Figure 1~8 Among them, a tunnel boring machine jacking support device, including a plurality of pre-embedded support anchor hole beams 5, the two ends of the support anchor hole beams 5 are provided with support positioning anchor holes 6; as figure 2 , 3 , Shown in 5, the support positioning anchor hole 6 in this example preferably adopts a square steel pipe.

[0038] Such as figure 1 , 3 Among them, the plurality of supporting anchor hole beams 5 are evenly distributed along the advancing direction of the tunnel boring machine, and at least two upper end surface center vertical beams 5 are located between the supporting positioning anchor holes 6 on the supporting anchor hole beams 5. Lines point to the inclined slide rails 9 of the same center. Such as figure 2 As shown in , of course, those skilled in the art can understand that there may be errors in the actual installation process, such as figure 2 O in 1 and O 2 As shown, try to make O by adju...

Embodiment 2

[0049] This example is the method using the device of Example 1, and the structures not described in this example are the same as those in Example 1.

[0050] Such as Figure 1~8 Shown in, a kind of construction method of tunnel boring machine jacking support device, comprises the following steps:

[0051] 1. Excavate a groove corresponding to the size of the tunnel boring machine 20 on the ground, pour a layer of plain concrete in the groove, and bury a plurality of inserting ribs 1 along the pushing direction and step-by-step pushing distance of the tunnel boring machine. The bolt 2 is welded on the inserted bar 1; the plain concrete refers to the concrete without bars or without reinforced bars.

[0052] 2. Install the steel backing plate 3 on the pre-embedded bolt 2 through the nut 4. In this example, the four corners of the steel backing plate 3 pass through the pre-embedded bolt 2, and are fixed between the upper and lower nuts 4, and are adjusted by the upper and lower...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com