Self-coupling type through-flow submersible electric pump

A submersible electric pump and through-flow technology, which is applied to non-variable pumps, parts of pumping devices for elastic fluids, pumps, etc., can solve the problems of increasing the force of civil structures, complicated installation process, and easy water leakage. , to achieve the effect of strengthening operation management, improving adaptability and increasing stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

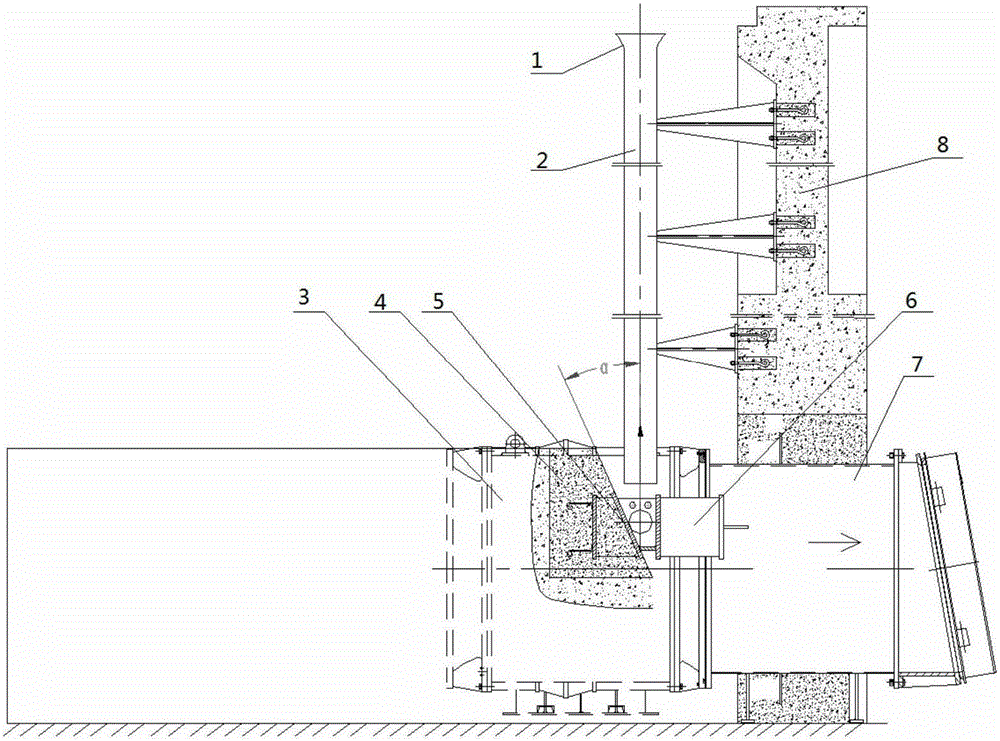

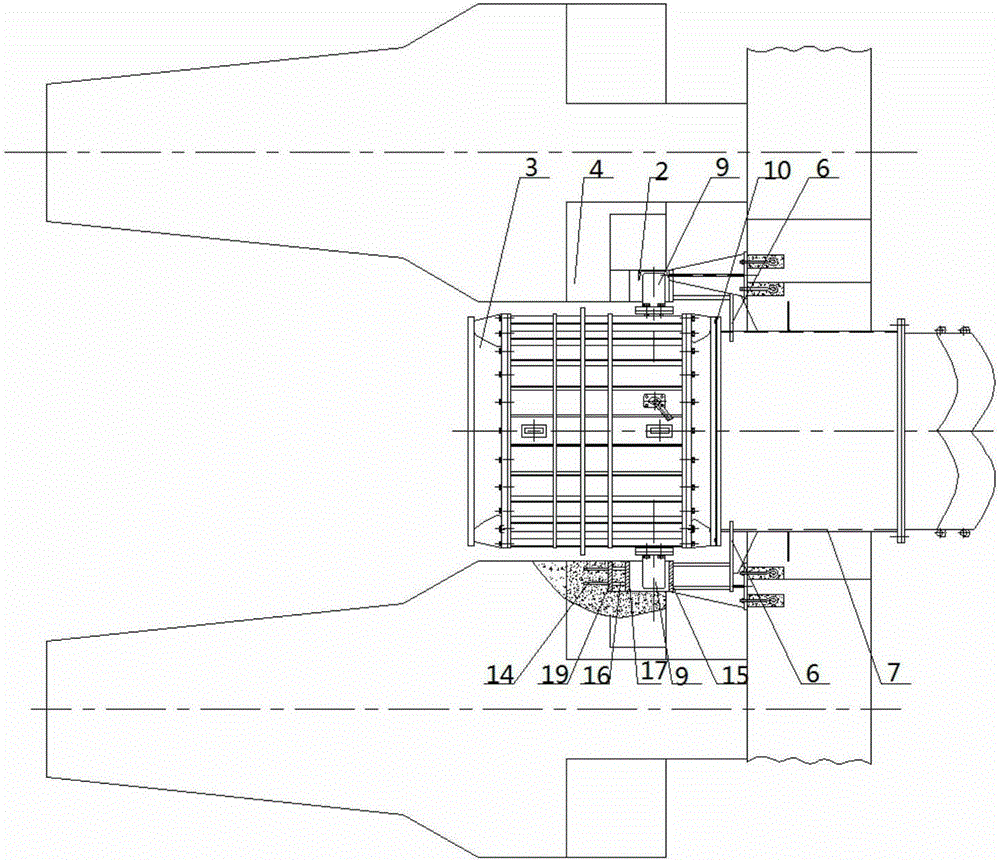

[0025] combine figure 1 and Figure 4 Two sets of symmetrical guide rod assemblies 9 are arranged on both sides of the water outlet of the full-through-flow submersible electric pump 3, and the guide rod assemblies 9 are welded into a whole with the stuffy cover 11, the cylinder 12 and the small bottom plate 13.

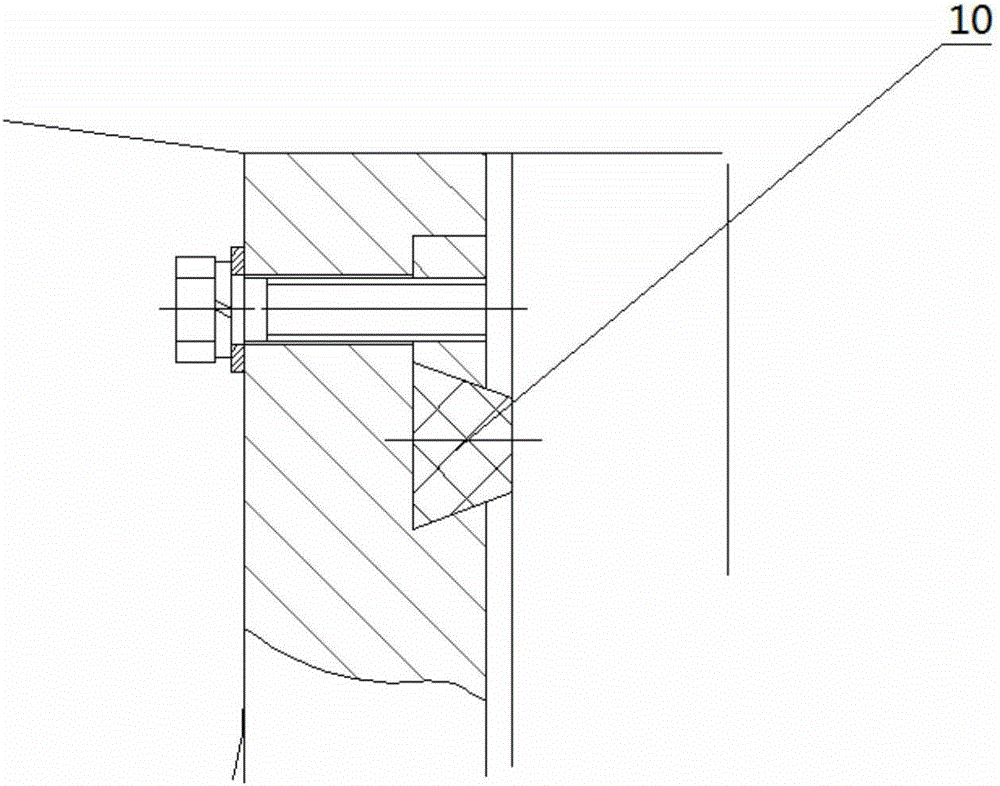

[0026] combine Figure 5 , the guide pendant 5 is to weld the thrust slope 17, the bottom plate 18 and a partition plate 15 into a whole, so that the bottom plate 18 and the partition plate 15 are vertical, and the angle formed by the thrust slope 17 and the bottom plate 18 is 180°-α±1° , and ensure that the guide rod assembly 9 slowly descends along the thrust slope 17 until the outlet flange surface of the full-flow submersible pump 3 completely coincides with the water inlet flange surface of the embedded pipe 7 during the coupling process, and the guide rod assembly 9 There is also a sufficient vertical safety distance between the bottom of the cylinder 12 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com