A multi-mode device for measuring the minimum miscible pressure of carbon dioxide

A carbon dioxide, miscible pressure technology, applied in measuring devices, measuring fluid pressure, instruments, etc., can solve the problems of uneven permeability distribution, can not represent the minimum miscible pressure and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

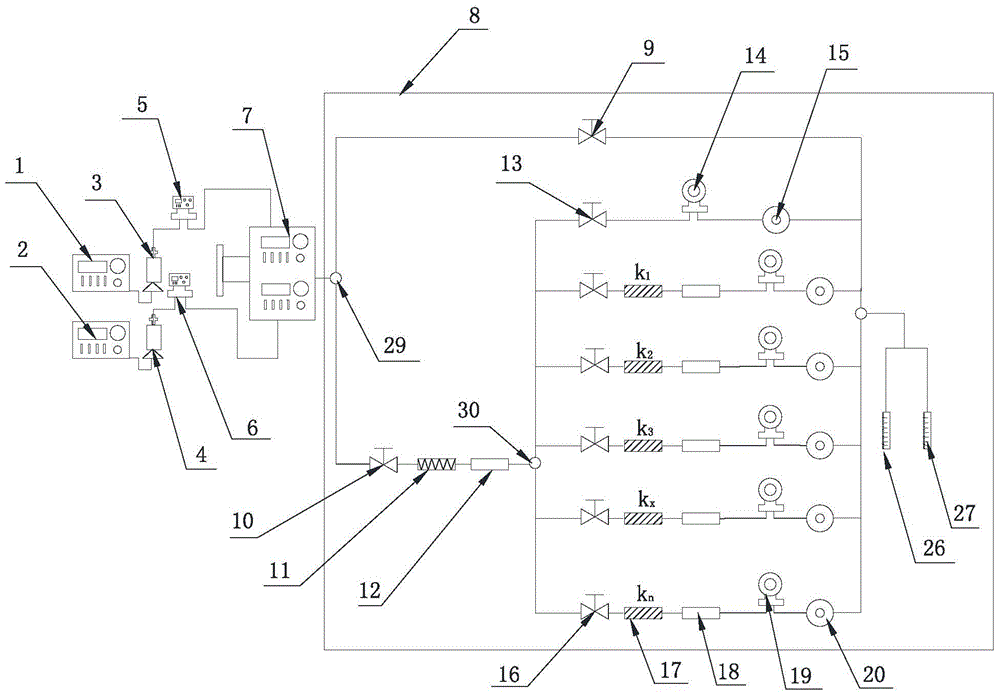

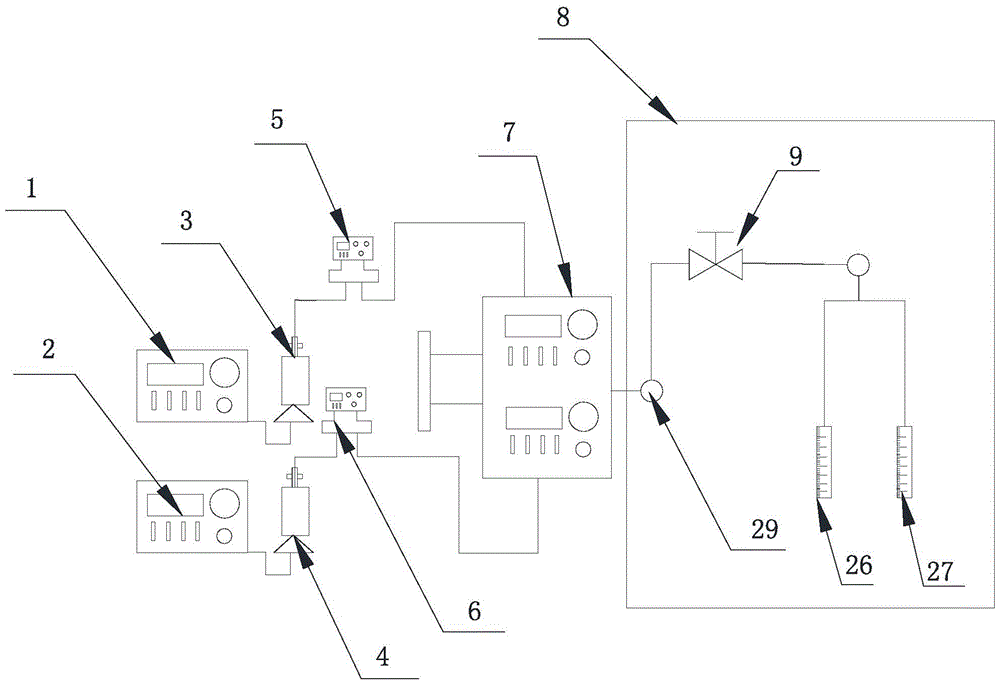

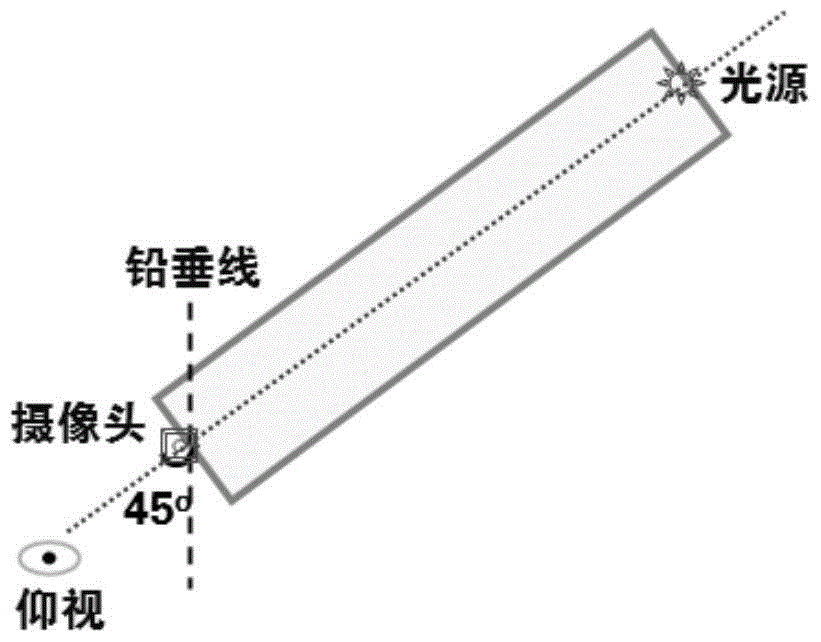

Method used

Image

Examples

Embodiment 1

[0039] The natural gas-containing crude oil used in this example has a viscosity of 9.8mPa·s at a temperature of 45°C, the fracture pressure of the reservoir is 27.9MPa, and the number of permeability between a certain injection-production well of the reservoir is 5, respectively K 3 : 2000×10 -3 μm 2 , K 4 : 1800×10 -3 μm 2 , K 5 : 1500×10 -3 μm 2 , K 6 : 1000×10 -3 μm 2 , K 7 : 800×10 -3 μm 2 ;

[0040] The thin tube miscible monitor, narrow tube pressure monitor, rock core mixed phase monitor and rock core pressure monitor are gas chromatographs of the model GC9310 produced by Shanghai Precision Company; adding reagent flow totalizer, carbon dioxide flow totalizer The instruments are all XSFT-LCD Chinese flow totalizers produced by Xisen Company; the constant pressure and constant speed pumps used are all HSB-1 high pressure constant speed and constant pressure pumps produced by Haian Petroleum Research Instrument Co., Ltd.

[0041] 1. Test the minimum miscib...

PUM

| Property | Measurement | Unit |

|---|---|---|

| breaking strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com