3D printer fault detection method

A 3D printer and fault detection technology, which is applied in the testing of machines/structural components, measuring devices, instruments, etc., can solve the problem of lack of repetition effect in fault detection of 3D printers, and achieve the effect of sufficient control flexibility and sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

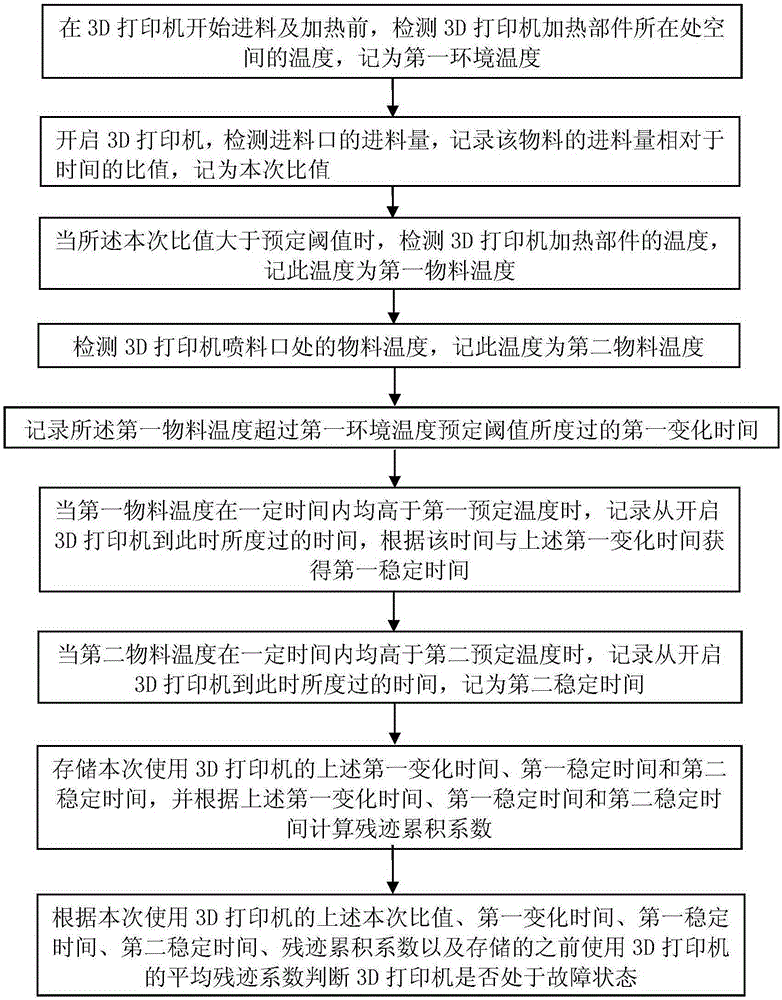

[0027] like figure 1 As shown, the 3D printer fault detection method of the present invention comprises the steps:

[0028] (1) Before the 3D printer starts feeding and heating, detect the temperature of the space where the heating component of the 3D printer is located, and record it as the first ambient temperature;

[0029] (2) Turn on the 3D printer, detect the feeding amount of the feed port, record the ratio of the feeding amount of the material relative to the time, and record it as this ratio;

[0030] (3) When the ratio this time is greater than a predetermined threshold, detect the temperature of the heating component of the 3D printer, and record this temperature as the first material temperature; the predetermined threshold here is generally determined according to the model of the specific 3D printer and the selected material of. For example, for the AURORA 3D printer, using MakerBotPLA blue filament, the threshold here can be set to 4.3mm / s.

[0031] (4) Detec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com