Furnace pressure control method for four-stage alloying furnace based on lpv system model

A technology of alloying furnace and system model, which is applied in electric fluid pressure control, metal material coating process, coating, etc., can solve the problems of increasing system order, inaccuracy, and increasing system complexity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0073] Below in conjunction with accompanying drawing and example the present invention is described in further detail.

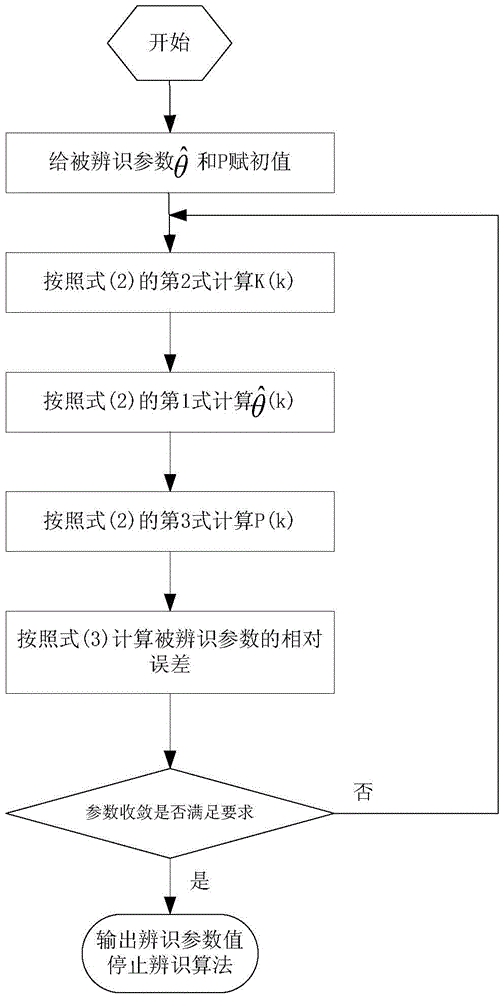

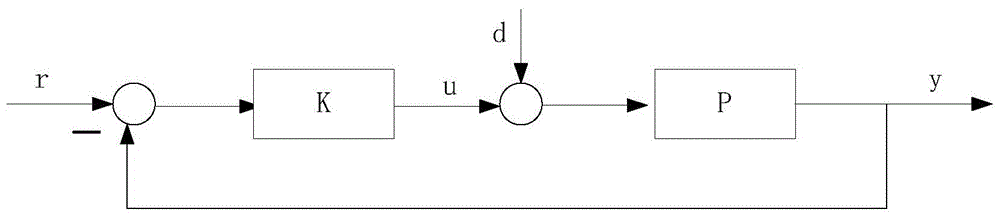

[0074] figure 1 For the LPV model of the present invention, set up the flow chart of algorithm, theta, K, P parameter among the figure are relevant intermediate parameters in setting up the mathematical model process; figure 2 It is the structural schematic diagram of the system, "K" is the controller, "P" is the controlled object, "r" is the input, "u" is the output of the controller, "d" is the disturbance, and "y" is the output of the system; The given and output of the system are compared to obtain a deviation signal. The controller generates a corresponding control signal according to the deviation signal and the PID control algorithm. The control signal is output to the cooling fan of the controlled object to adjust the speed of the cooling fan and change the The wind pressure of the cooling fan changes the furnace pressure of the alloying furnace, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com