Calculation method of gradient material macro equivalent elastic modulus

A technology of equivalent elastic modulus and gradient materials, which is applied to the analysis of materials, strength characteristics, measuring devices, etc., and can solve the problem of low efficiency in obtaining macroscopic equivalent elastic modulus

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0059] Reference will now be made in detail to the exemplary embodiments, examples of which are illustrated in the accompanying drawings. When the following description refers to the accompanying drawings, the same numerals in different drawings refer to the same or similar elements unless otherwise indicated.

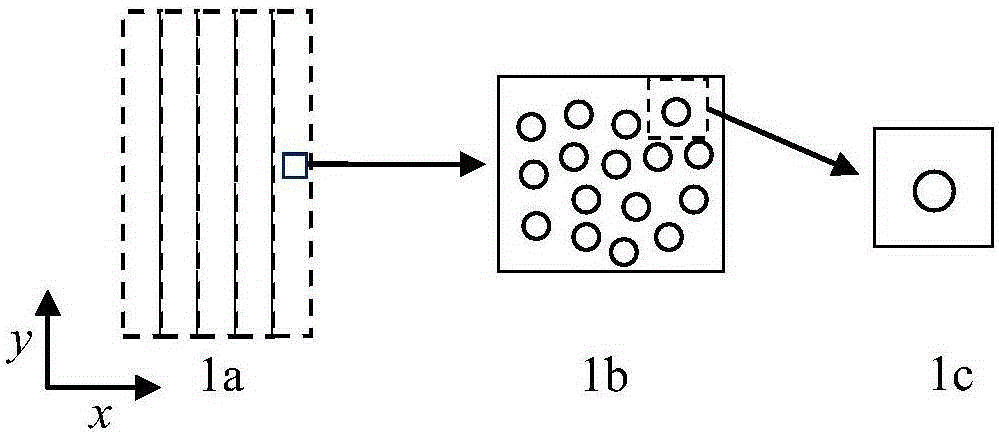

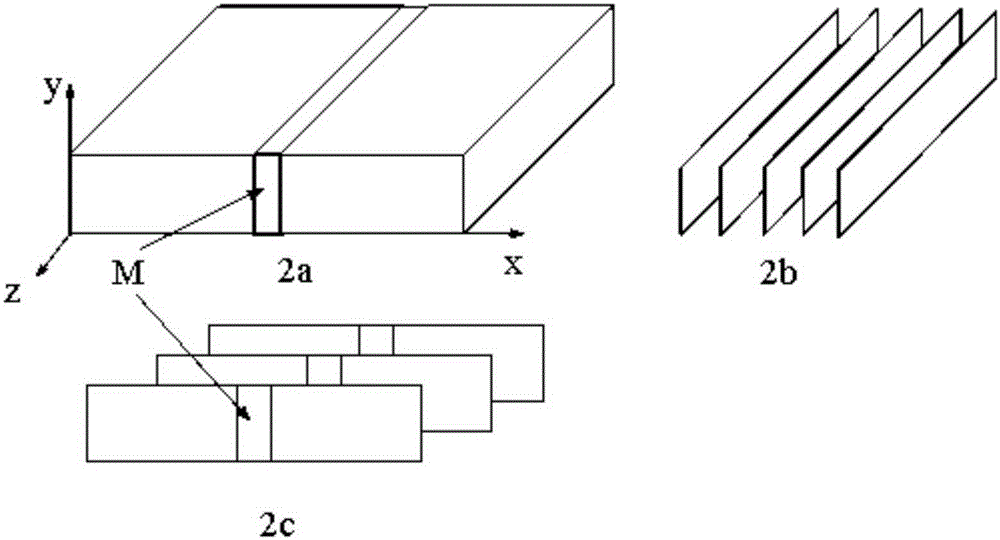

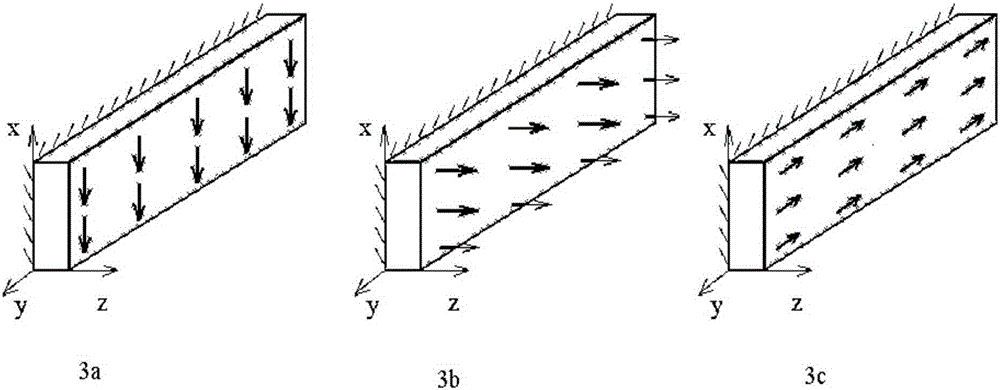

[0060]In the method for calculating the macroscopic equivalent elastic modulus of the gradient material of the present invention, the gradient material is formed in a transition zone between two predetermined isotropic materials, and the mechanical properties of the material in the transition zone change in a gradient along a predetermined direction. Based on the fact that the mechanical properties of the transition zone change in a gradient between two-phase materials, we adopt the following assumptions based on the idea of particle inclusion and field average theory in the mesomechanics method:

[0061] 1) Assume that the transition zone is a particle inclusion com...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com