Robot grabbing method and system

A robot and functional relationship technology, applied in the field of robotics, can solve the problems of difficulty in grasping a type of workpiece, inability to guarantee real-time and reliability, and slow grasping.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

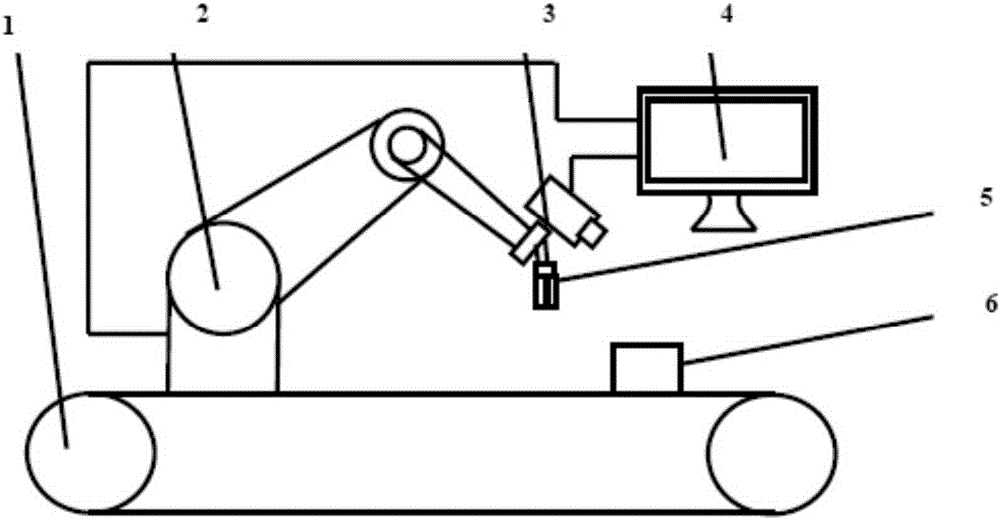

[0062] as attached figure 1 As shown, a robot grasping system based on the fusion of visual and environmental attraction domains includes a robot 2, a camera 3, a remote control computer 4, a four-finger gripper 5 and a workpiece 6; the four-finger gripper 5 and the camera 3 are fixed on the robot 2. At the end of the sixth axis (that is, the end of the axis connected to the end effector), the image plane of the camera 3 is set to be perpendicular to the direction of the fingers of the four-fingered gripper 5; the camera 3, the remote control computer 4 and the robot 2 are electrically connected in turn. Optionally, the system may also include a conveyor belt 1 .

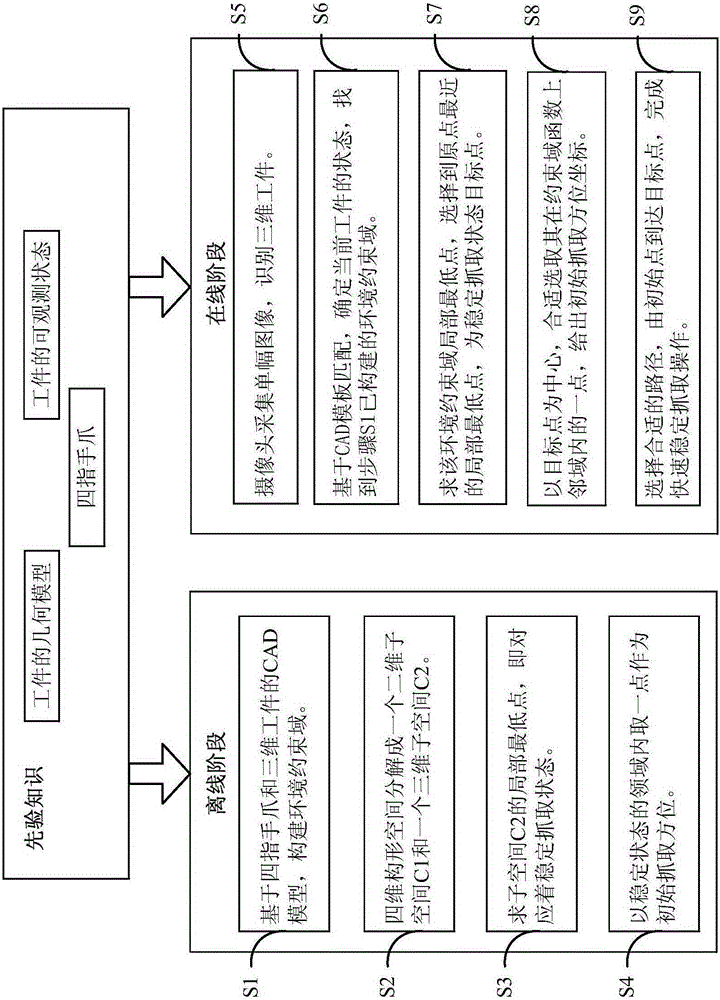

[0063] as attached figure 2 As shown, a robot grasping method based on the fusion of visual and environmental attraction domains includes the following steps:

[0064] offline stage

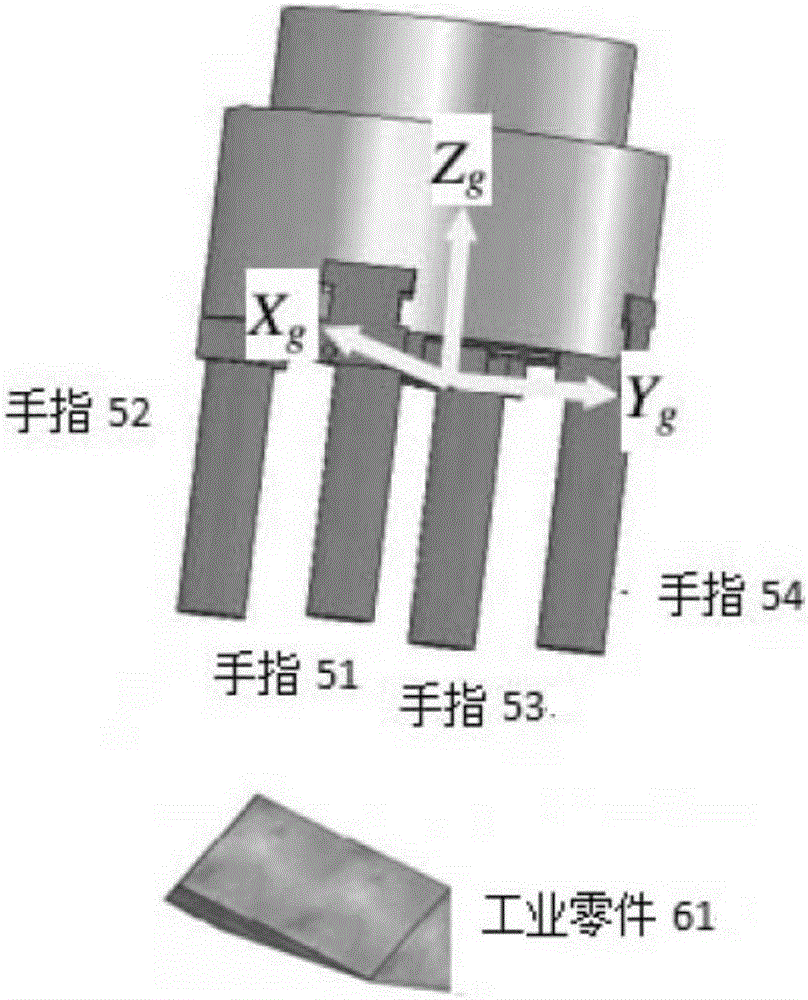

[0065] Step S1: If a four-fingered gripper is used to grab a convex hexahedron workpiece, firstly establish a gripper coordinate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com