Air adjusting and heat dissipating self-cleaning transformation cabinet

A self-cleaning, transformer cabinet technology, applied in the substation/distribution device housing, substation/switch layout details, and substation/switchgear cooling/ventilation, etc., can solve the problem of dust, hidden safety hazards, and low cooling and heat dissipation efficiency And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

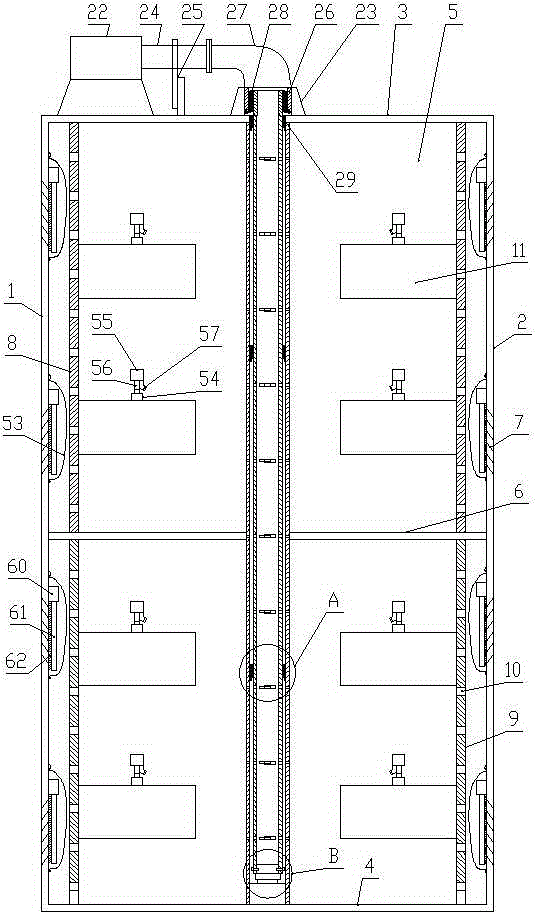

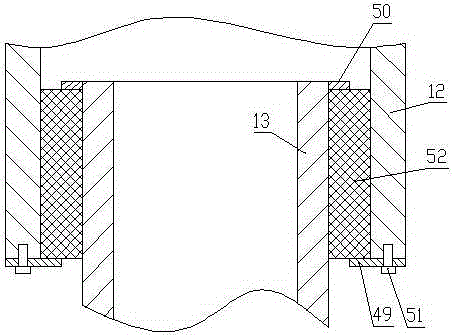

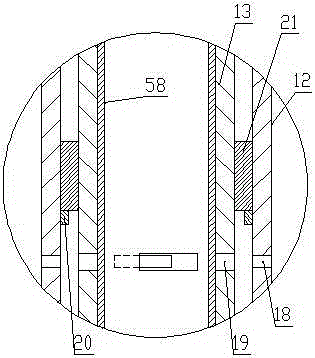

[0028] Such as Figure 1-Figure 7 As shown, the air conditioning and heat dissipation self-cleaning transformer cabinet of the present invention comprises a cabinet in the shape of a cuboid, and the cabinet consists of a left side panel 1, a right side panel 2, a top panel 3, a bottom panel 4, a rear side panel 5 and a cabinet door (not shown in the figure) is composed of a horizontal partition 6 between the left side panel 1 and the right side panel 2, louvers 7 are respectively arranged on the left side panel 1 and the right side panel 2, the inner wall of the left side panel 1 and the right side panel The inner wall of the side plate 2 is provided with a cleaning mechanism at the shutter 7, and a left vertical plate 8 and a right vertical plate 9 are arranged between the top plate 3 and the bottom plate 4. The left vertical plate 8 is parallel to and adjacent to the left side plate 1, and the right vertical plate 9 is parallel and adjacent to the right side plate 2, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com