The receiving end of the bridge arm wound flat magnetic core applied to the wireless power supply of electric vehicles

A flat magnetic core and wireless power supply technology, which is applied in the direction of transformer/inductor coil/winding/connection, transformer/inductor core, electrical components, etc., can solve the problems of poor power supply efficiency and achieve good magnetic field shielding effect and coupling High degree, good electromagnetic compatibility effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

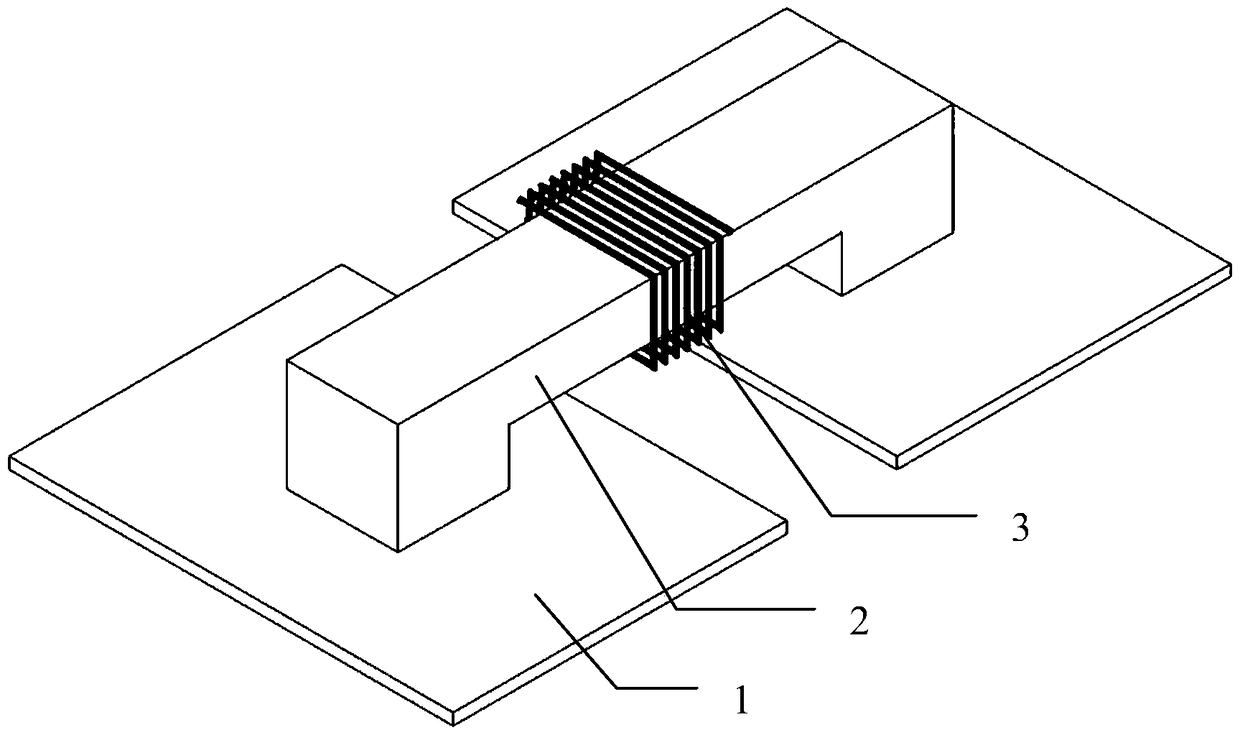

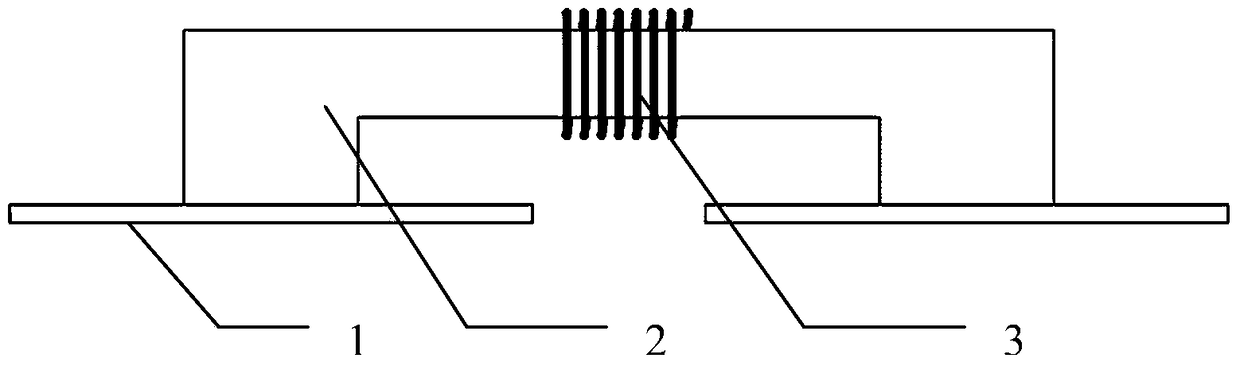

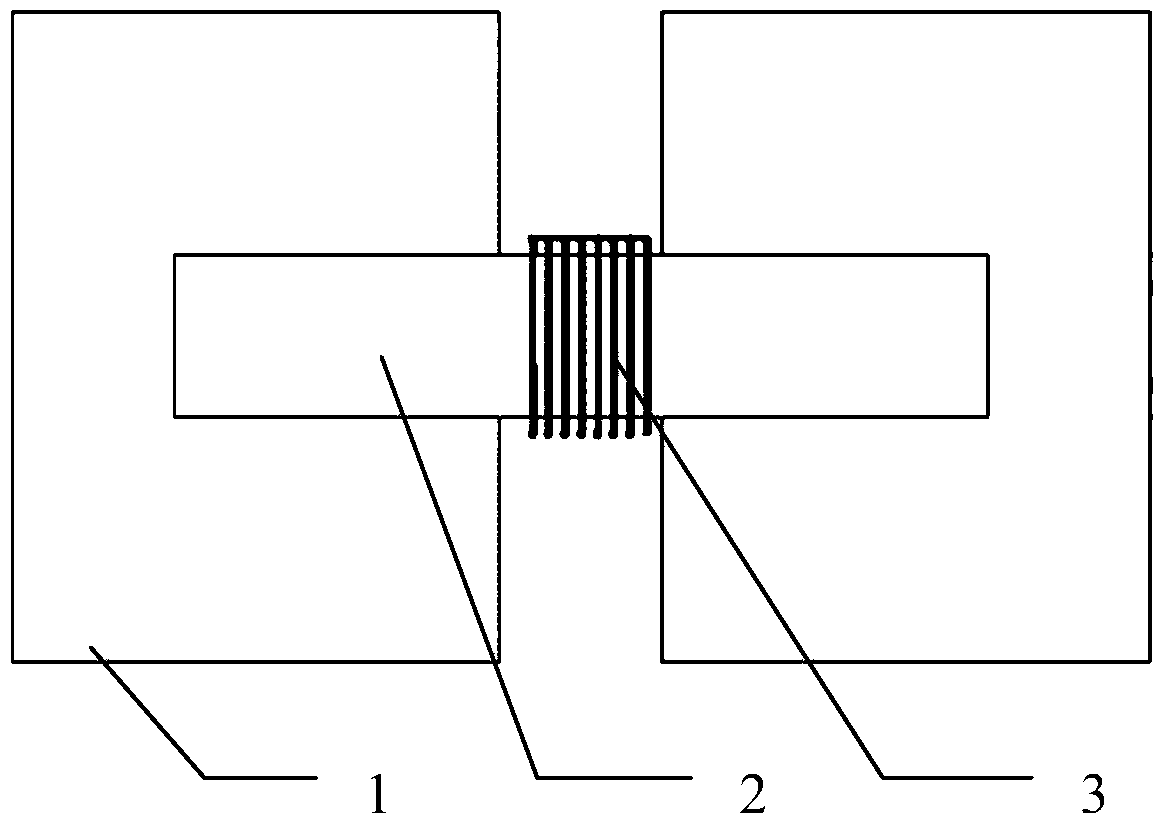

[0024] Specific implementation mode one: the following combination Figure 1 to Figure 11 This embodiment is described. The receiving end of the bridge arm wound flat magnetic core applied to the wireless power supply of electric vehicles described in this embodiment is adapted to the bipolar wireless transmitting guide rail of the wireless energy transmitting end. The adjacent magnetic pole of the transmitting guide rail The direction of the magnetic field is opposite; the receiving end of the flat magnetic core includes n flat magnetic cores 1, bridge arm magnetic cores 2 and n-1 receiving coils 3,

[0025] n planar magnetic cores 1 are arranged in parallel, and there is a gap between two adjacent planar magnetic cores 1, and bridge arm magnetic cores 2 are sequentially connected between n planar magnetic cores 1, and two adjacent planar magnetic cores 1 The receiving coil 3 is helically wound centrally on the core segments of the bridge arm magnetic core 2 .

[0026] In th...

specific Embodiment approach 2

[0028] Specific implementation mode two: the following combination Figure 1 to Figure 8 The present embodiment will be described. This embodiment will further describe the first embodiment. The n ends of the bridge arm magnetic cores 2 are respectively connected to the centers of the corresponding planar magnetic cores 1 .

specific Embodiment approach 3

[0029] Specific implementation mode three: the following combination figure 1 , figure 2 , Figure 5 and Figure 6 Describe this embodiment mode, this embodiment mode will further illustrate Embodiment 1 or 2. The bridge arm magnetic core 2 is composed of n vertical segments and a horizontal segment, and the n vertical segments and a horizontal segment are sequentially connected to each other. n-1 rectangular frames together; or the bridge arm magnetic core 2 is n-1 arc-shaped frames connected together in sequence.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com