Directional rotation single-phase self-starting permanent-magnet synchronous motor

A technology of directional rotation and permanent magnet synchronization, applied in the direction of starting devices, electronic commutators, etc., can solve problems such as high cost, high anti-interference ability requirements, and unstable product quality, so as to achieve stable product performance and reduce complexity Sexuality and cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

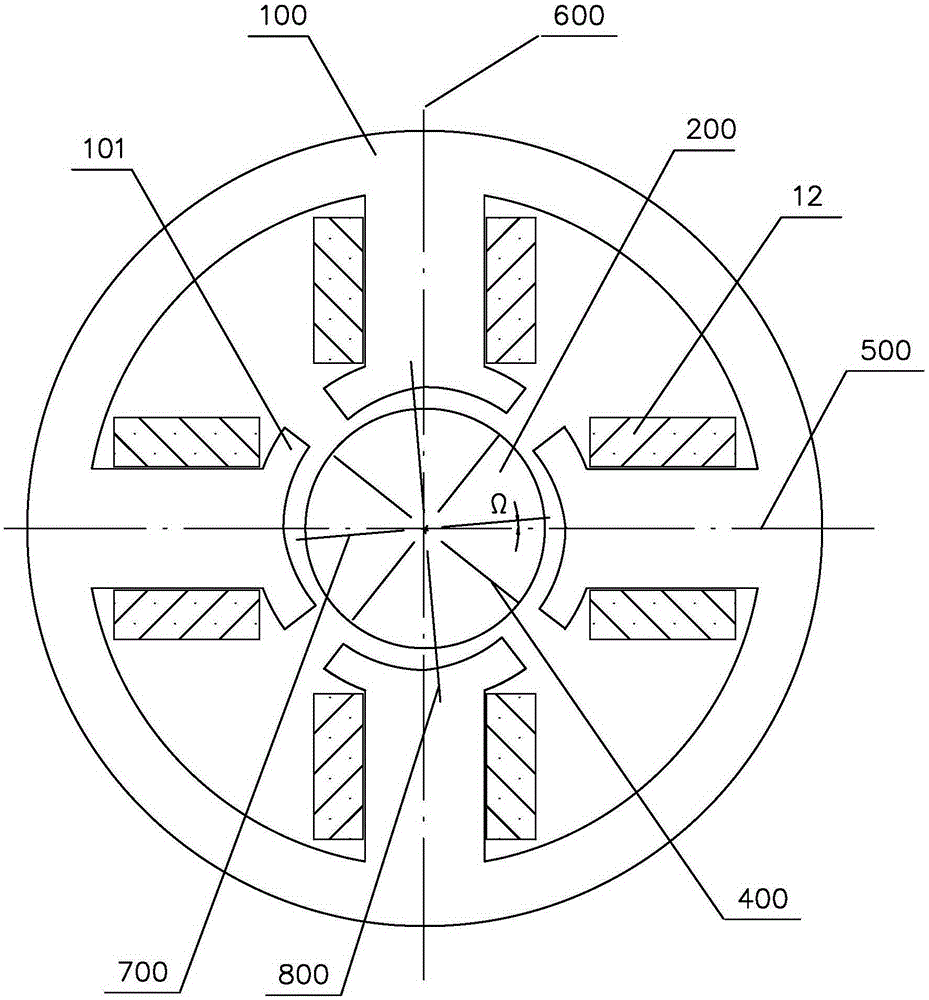

[0023] The basic structure of the electromagnetism of the embodiment of the present invention is as follows: figure 1 shown, which includes:

[0024] ——The rotor 200 is a 4-pole permanent magnet rotor whose cross section is divided into four symmetrical 90° sectors by two mutually perpendicular symmetry axes 400 and whose radial magnetization is N, S, N, S;

[0025] - The stator 100 is composed of a circular iron core 101 with 4 salient poles and a winding 12; the winding 12 is a coil element with an insulating frame wound on each of the 4 salient poles, and then connected in series according to the winding direction to form 4 poles, and Therefore, when energized, a 4-pole main magnetic flux passing through the air gap between the stator and rotor is generated;

[0026] ——The width of the air gap between each salient pole of the stator core 101 and the rotor 200 gradually narrows in the counterclockwise direction; Attraction, the geometric axis of each pole, that is, the per...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com