Rapid disperse dosage form containing levetiracetam

A dosage form, dispersed technology, applied in the treatment of levetiracetam treatment response disease, disease or disease state, the field of preparation of said dosage form, can solve the problem of not disclosing suitable dosage form, low brittle hardness, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0127] Embodiment 1 prepares the orodispersible dosage form of three-dimensional printing

[0128] The following method was used to prepare a three-dimensionally printed orodispersible dosage form comprising a matrix comprising LEVs. The composition and amounts used for the printing fluid and loose powder are as follows:

[0129]

[0130]

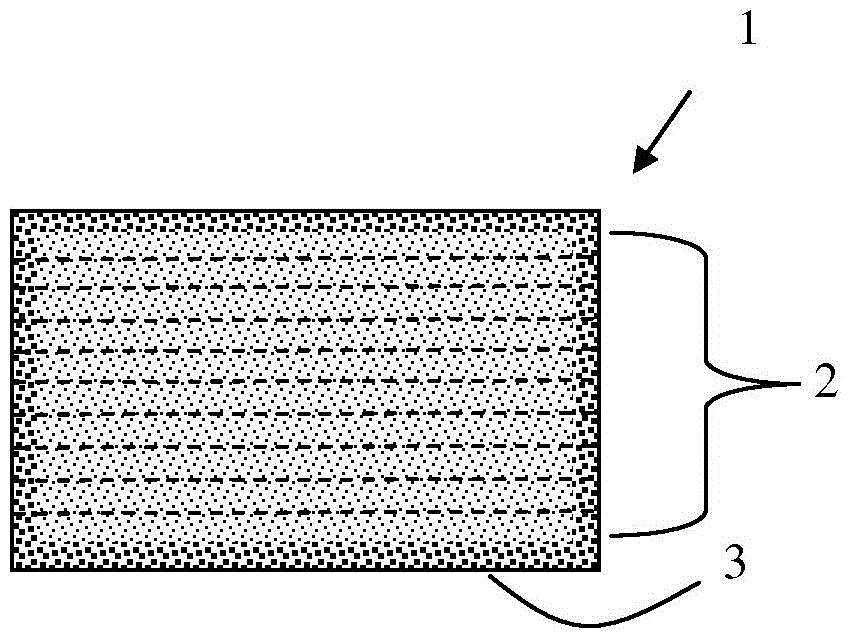

[0131] An incremental layer of loose powder of predetermined thickness is spread over the previous powder layer, and printing fluid is applied in droplets to bind the particles therein according to a predetermined saturation level, row spacing, and printing fluid flow rate. This two-step process was completed until a substrate containing the target amount of printed incremental layers was obtained.

[0132]Any three-dimensional printer device components known or described herein can be used, but these exemplary formulations can be prepared with a Coriolis Instrument (Dimatix / Spectra Technology Integration, model: Coriolis RP1). The ...

Embodiment 2

[0136] Example 2 Fast Dispersing Flakes with Altered Structure in Different Bulk Layers

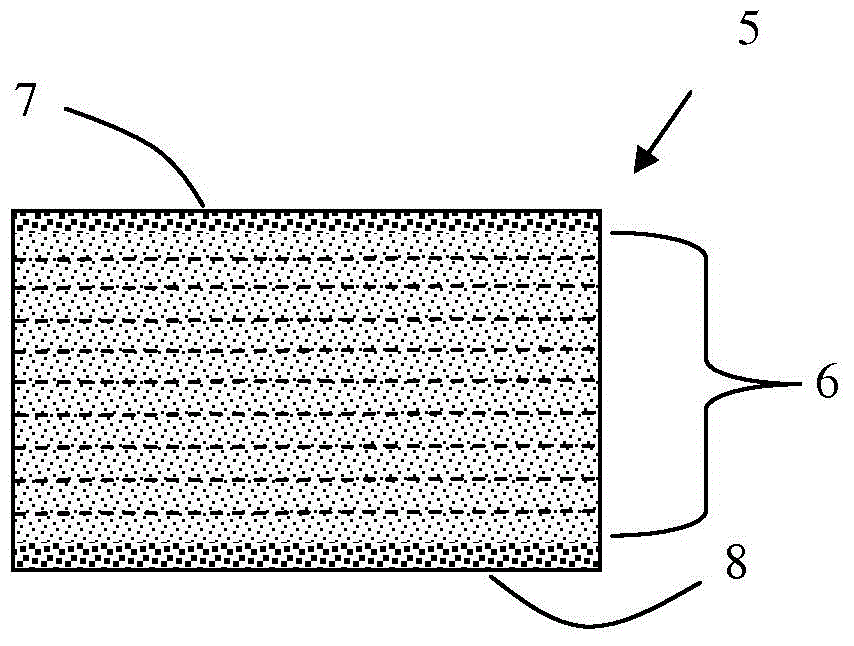

[0137] Preparation of taste-masked three-dimensionally printed orodispersible dosage forms with altered structure in the bulking layer

[0138] According to the 3DP method described above, but it can be carried out in several different ways to prepare dosage forms of different structures varying in hardness and bulk layer composition. The following method provides a hardness of the upper and lower surfaces of the wafer that is greater than the hardness of the inner portion of the wafer. This strategy facilitates the generation of parts in flakes with different mechanical properties. This approach is used to design flakes where the composition of the top and bottom layers differs from that of the middle layer. This design results in flakes with stronger top and bottom layers, which increase hardness and reduce brittleness, and a large middle part with less hardness, which allows the flak...

Embodiment 3

[0149] The characterization of embodiment 3 dosage form

[0150] The following method was used to characterize the 3D printed solid porous dispersion matrix.

[0151] brittleness

[0152] The resistance of the matrix to fracture was analyzed using the Tablet Friability Test (USP method ). The test used a VanKel brittleness tester (Model 45-2000, Varian, USA) equipped with a drum size of 285 mm in diameter and 39 mm in depth, rotated 100 times at 25 rpm. A minimum of 10 flakes are dropped per revolution through curved protrusions extending from the middle of the drum to the outer wall. Thus, at each inversion, the tablets are rolled or slid about 130 mm onto the drum or onto the tablets next to each other. All loose powder was removed from the tablet and the tablet was weighed before and after 100 cycles.

[0153] surface material

[0154] The matrix was inspected visually with or without a microscope. The surface texture is analyzed to determine whether it is rough o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com