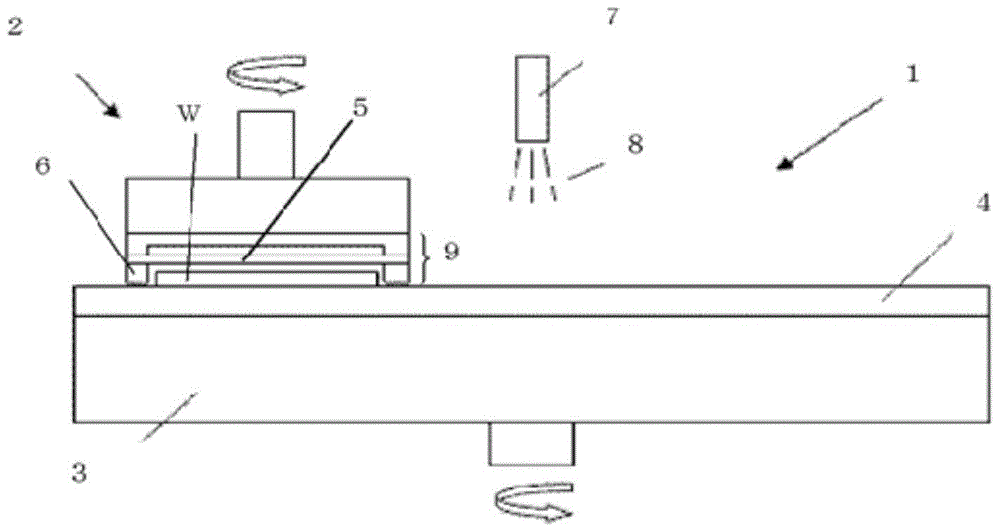

workpiece grinding device

A grinding device and workpiece technology, applied in the field of workpiece grinding devices, to achieve the effect of being difficult to undulate or damage, simple and uniform formation, and high flatness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0069] The workpiece was polished using the workpiece polishing device of the present invention, and the flatness and damage defect rate of the polished workpiece were evaluated.

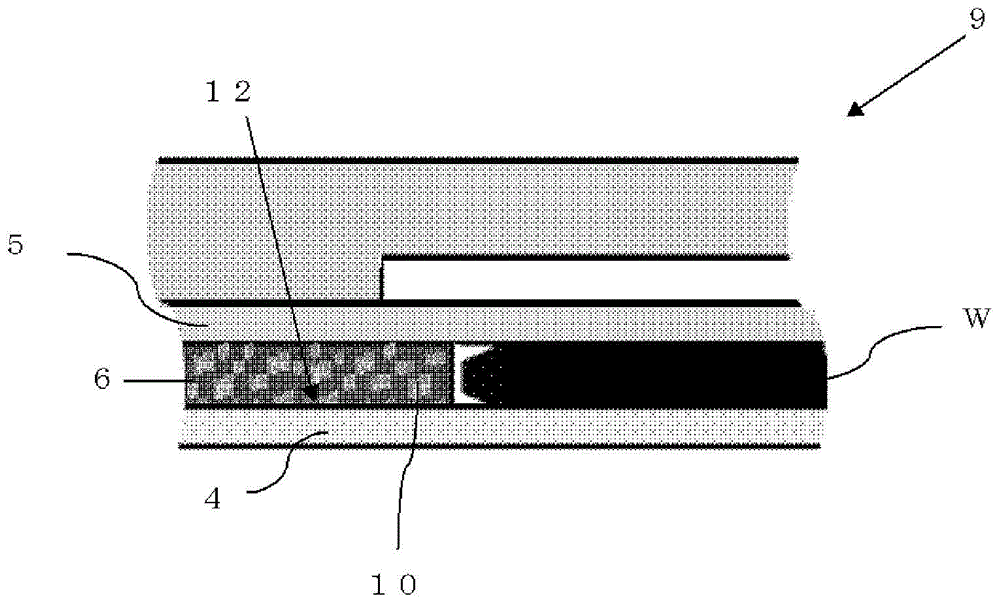

[0070] In Example 1 used figure 1 grinding device. The grinding head of the grinding device is as figure 2 As shown, in addition to templates, use the same Figure 8 The grinding head is the same as the grinding head. The template at this time is produced by the following method. First prepare bisphenol A type epoxy resin, which is added with a glass filler whose concentration has been adjusted to a maximum external dimension of 2mm, and then make an epoxy resin prepreg containing glass fibers, which is coated with a sprayer. A bisphenol A type epoxy resin was clothed, and this prepreg was laminated on the pressing surface side of the pressing abrasive cloth, and press-molded into a ring shape. The template had a thickness of 750 μm, and the surface occupancy of the filler exposed on the pres...

Embodiment 2

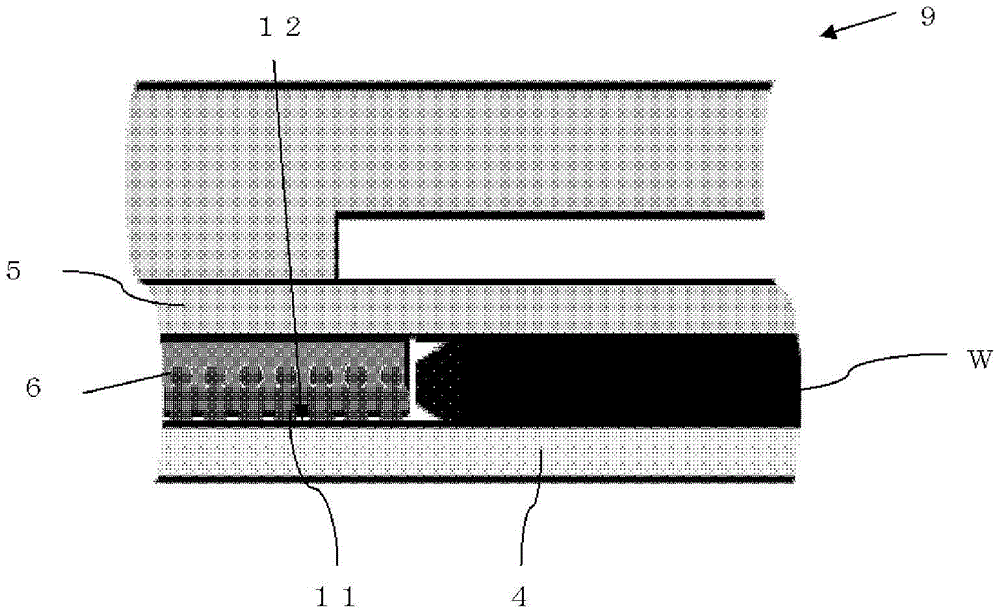

[0073] The workpiece was polished under the same conditions as in Example 1 except that the template was different from that described below, and the flatness and damage defect rate of the polished workpiece were evaluated. The template at this time is produced by the following method. A flat-woven glass fiber cloth with an aspect ratio of 0.5 mm and a thickness of 0.18 mm was impregnated with a bisphenol A epoxy resin, and dried to produce a prepreg for the surface. This prepreg was laminated on the pressing surface side of the pressing abrasive cloth, and press-molded into a ring shape with a thickness of 760 μm. Then, the pressing surface of the pressing polishing cloth was polished so that the glass fibers were exposed in a net shape. In this template, the surface occupancy of the glass fiber cloth exposed on the pressing surface of the pressing abrasive cloth was 16%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com