Method for heating a paver screed

A technology for paving machines and heating devices, applied in ohmic resistance heating, roads, roads, etc., can solve the problems of generator load, reduce the life of heating elements, and reduce the life of fuel consumption, achieve simple and stepless changes, and achieve energy efficiency. , the effect of saving fuel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

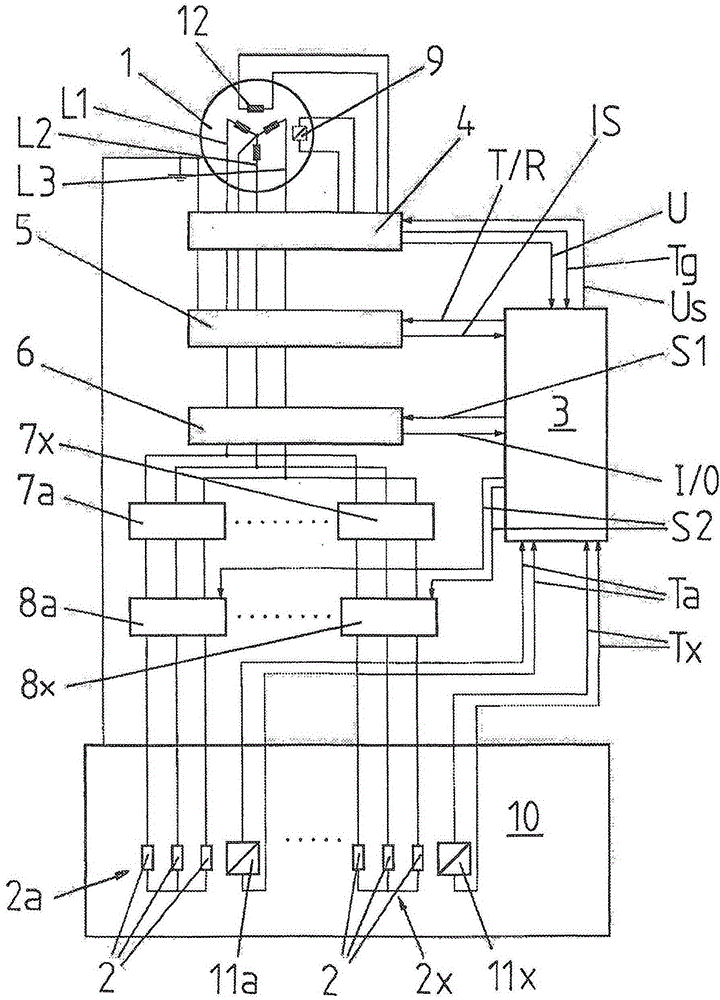

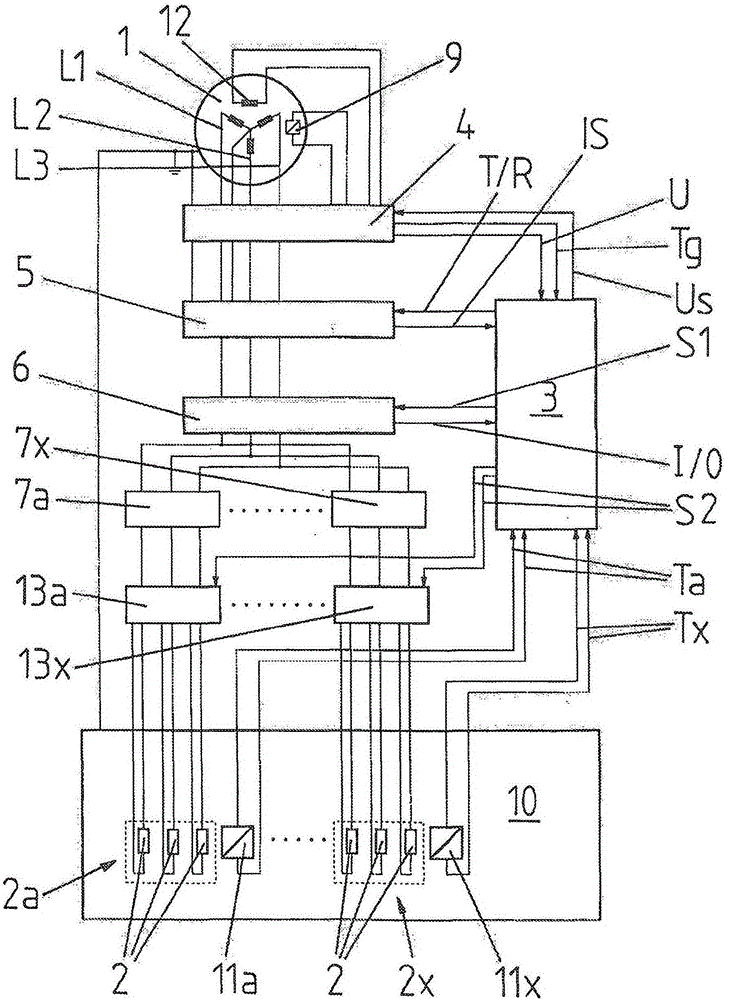

[0042] figure 1 A schematic diagram showing the heating device of the paving leveling ruler of the first paving machine according to the present invention, including an associated control unit for implementing the method according to the present invention.

[0043] As can be seen, the heating device includes the following main components: a three-phase current generator 1; a plurality of heating element groups 2a-2x respectively include three identical resistance heating elements 2, which are arranged in the paving machine evenly. The mud ruler 10; and a computer-aided control unit 3 for controlling or setting the heating power of each heating element 2.

[0044] The groups 2a-2x of heating elements 2 pass through a common voltage regulator 4, a common ground monitoring device 5 (insulation measuring instrument, fault current monitoring), a common main protection device 6 (electric isolation) and each group 2a- 2x is connected to the three-phase L1, L2, and L3 of the three-phase cu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com