Electric tea frying machine with real-time temperature control system and temperature control method of electric tea frying machine

A technology of temperature control system and tea frying machine, applied in control/regulation system, temperature control, tea treatment before extraction, etc., can solve the problem of lack of real-time monitoring of tea temperature, to ensure the quality of fried tea, quality assurance, and temperature detection full effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

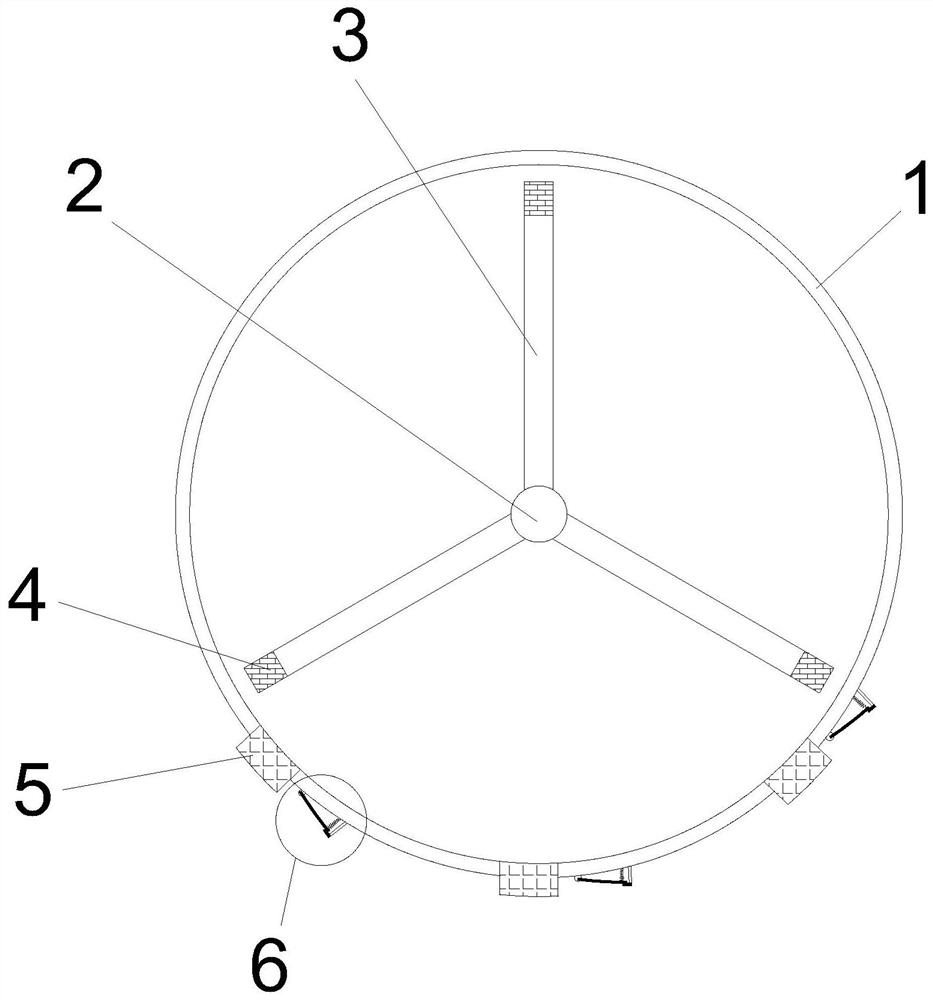

[0034] This embodiment proposes an electric frying tea machine with a real-time temperature control system, refer to figure 1 , including a barrel-shaped casing 1, a horizontal shaft 2 is arranged at the center of the inner axis of the barrel-shaped casing 1, and three dials are fixed on the horizontal shaft 2, and each dial includes three paddles 3 whose circumferences are distributed on the horizontal shaft. The bottom of the shell 1 is provided with a real-time temperature control system module and a segmented electric heating module.

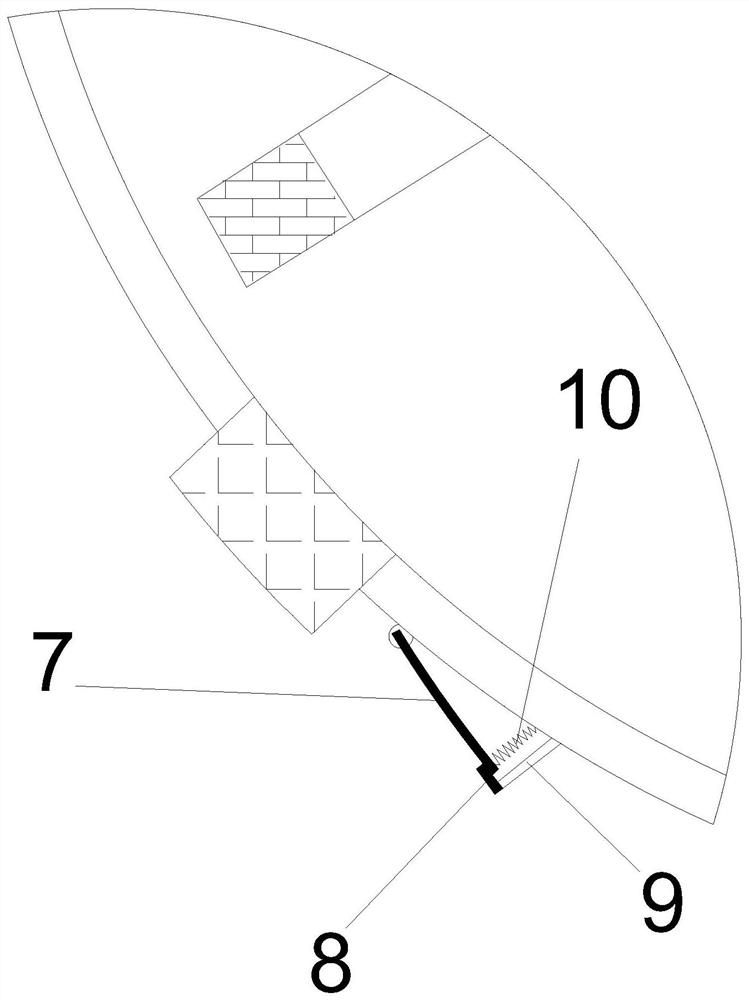

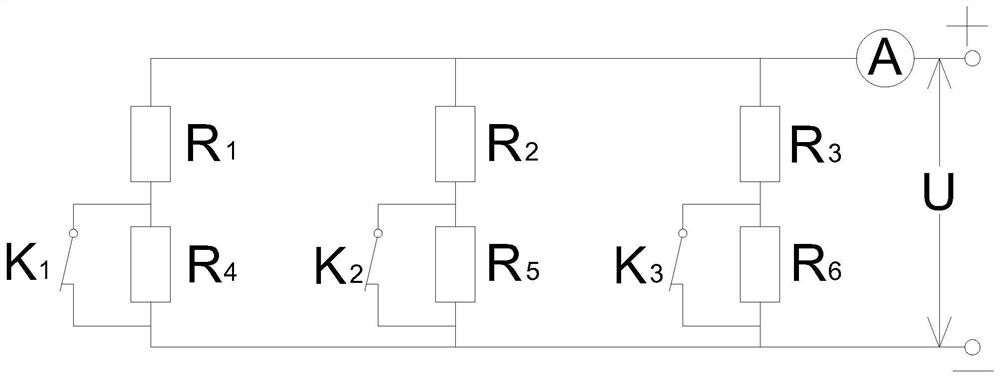

[0035] The real-time temperature control system module includes: 3 thermistors 5, distributed in a matrix at the bottom of the barrel-shaped casing of the tea frying machine; 3 fixed-value resistors, respectively connected in series with thermistors 5; The resistors are connected in parallel to control the on-off of the fixed-value resistors; the current detection circuit is connected to the thermistor 5 and the fixed-value resistors to meas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com