Valve for metering fluid, containing a filter device

A filter, fluid technology applied to a valve that measures fluid, placing and forcing the fluid to flow through the filter surfaces of a strainer and a fine filter in sequence. It can solve problems such as sealing problems and filter structure damage, and achieve the effect of preventing sealing problems and simple manufacturing technology.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

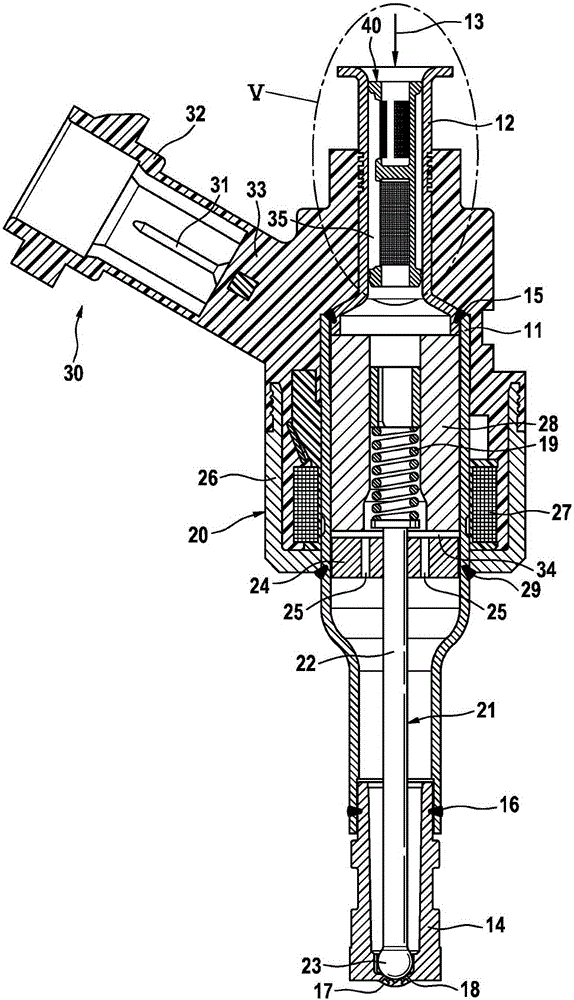

[0020] For example in internal combustion engines, in figure 1 The valve for metering fluid shown in longitudinal section in the figure is used as an injection valve for injecting fuel oil or fuel into the intake manifold or combustion chamber of an internal combustion engine or as a metering valve for aqueous urea solution into the exhaust gas tract of an internal combustion engine valve. The valve can also be used in heating installations operating with hot oil or gas and in gas engines.

[0021] exist figure 1 The valve for metering fluids shown in longitudinal section has a tubular valve housing 11 into which a connecting sleeve 12 with a fluid inlet 13 is inserted at one end and in which A hollow valve seat carrier 14 is loaded into the other side end of the valve. The connecting sleeve 12 and the valve seat carrier 14 are integrally connected to the valve housing 11 . The material fit is produced respectively by welding, as in this figure 1 as shown by weld 15 or 16...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com