A Method of Improving Calculation Accuracy of Head Temperature of Hot-rolled Intermediate Billet

A technology of head temperature and calculation accuracy, applied in metal rolling, metal rolling, rolling mill control devices, etc., to achieve the effect of reducing workload, reasonable setting of rolling mill parameters, and reducing the number of degraded products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

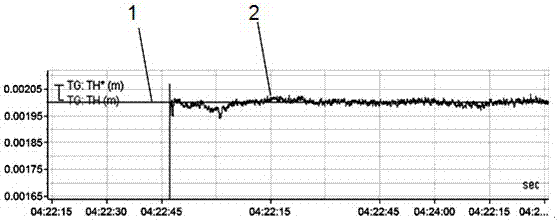

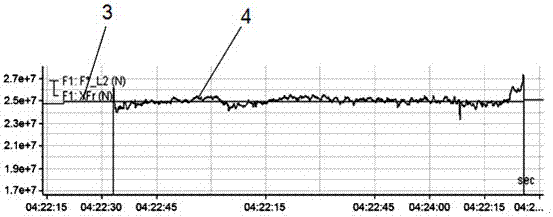

Image

Examples

Embodiment Construction

[0025] The present invention adopts the following technical solutions:

[0026] 1. Expand the linear interval of the Siemens secondary model to 25% to reduce the influence of low temperature on linear calculation.

[0027] 2. Check the final result of linear calculation. While linear calculation, calculate the average value of the temperature value used in linear calculation, and then compare the two. If the deviation is greater than 15°C, use the average value algorithm.

[0028] 3. In the Siemens second-level model, filter the temperature data with the value "-1" uploaded by the automation first-level, that is, as long as the temperature value val is "-1", the Siemens second-level model will determine that it is invalid data, and proceed Filter out, in the subsequent linear calculation, the model will not use this value.

[0029] 4. In the Siemens second-level model, different temperature default values are set according to different strip thicknesses to ensure that when the first...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com