egw and gmaw compound welding system

A composite welding and welding box technology, which is applied in welding equipment, welding accessories, arc welding equipment, etc., can solve the problems of low welding efficiency and achieve high welding quality, improved welding efficiency, and precise welding control.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

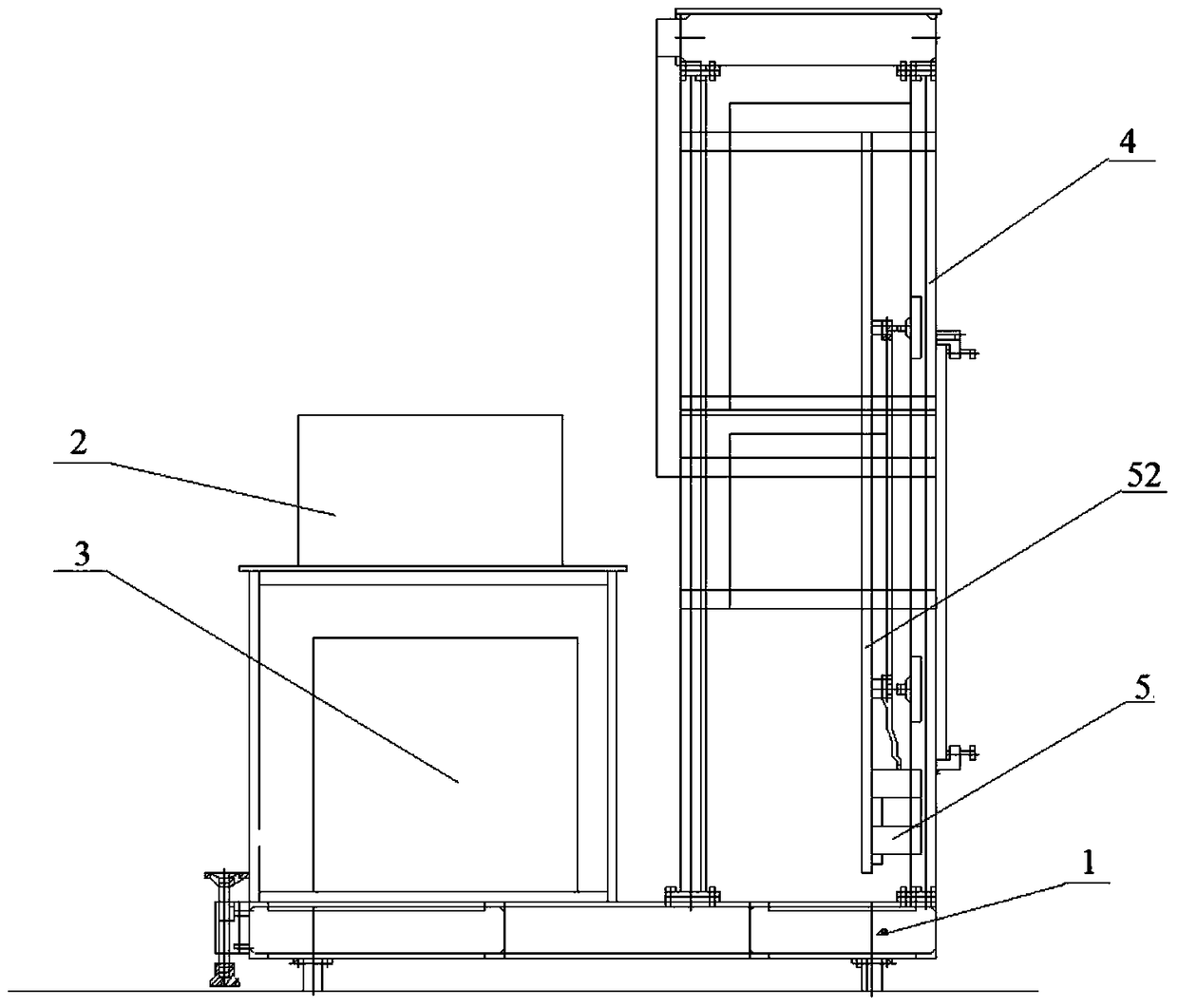

[0022] Embodiment 1: A kind of EGW and GMAW composite welding system, such as figure 1 As shown, it includes a frame 1, a welding power source 2 fixed on the frame 1, a welding box 4 and a cooling water tank 3, and the welding power source 2 is fixed above the cooling water tank 3 through a power supply bracket.

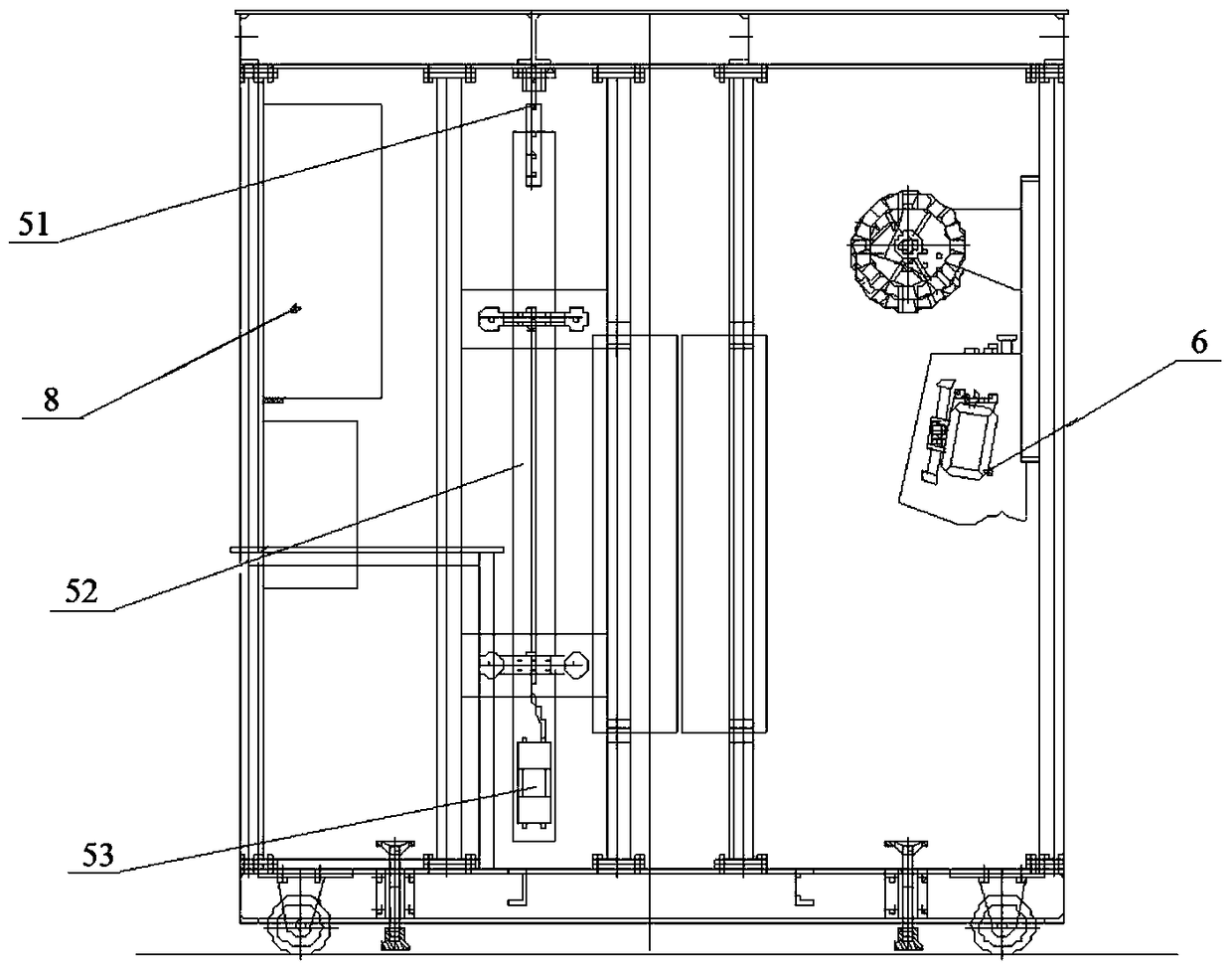

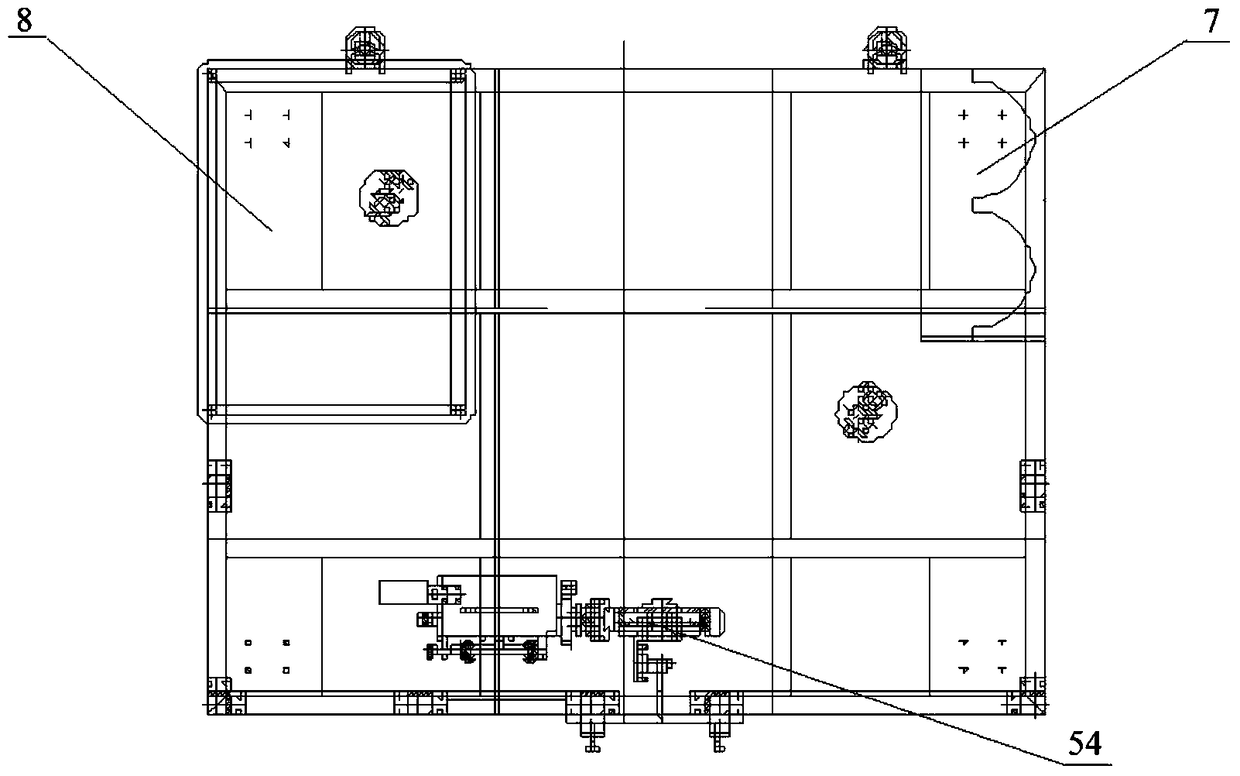

[0023] The welding box 4 is provided with a welding mechanism 5, a welding wire feeding mechanism 6, a shielding gas supply mechanism 7 and an electric control box 8. The welding mechanism 5, the welding wire feeding mechanism 6 and the shielding gas supply mechanism 7 are respectively connected to the electric control box 8 Corresponding electrical control components in the connection.

[0024] The electric control box 8 has two working modes, respectively EGW working mode and GMAW working mode, and each electrical control element in the two working modes independently controls the welding mechanism 5, the welding wire feeding mechanism 6 and the shielding gas suppl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com