Pneumatic positioning mechanism

A positioning mechanism and positioning claw technology, which is applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of heavy workload and high error rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

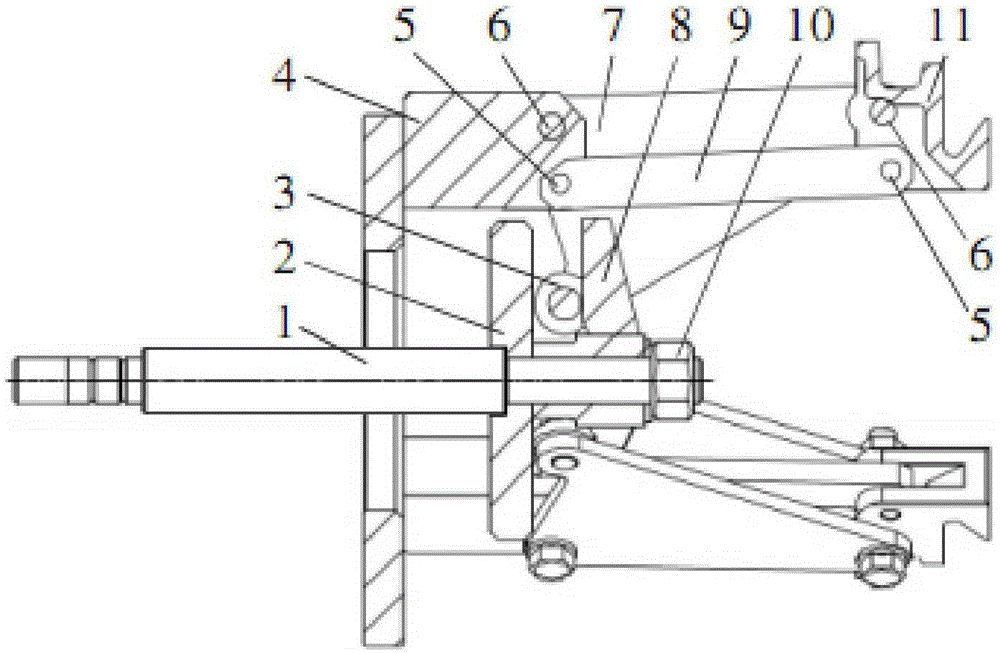

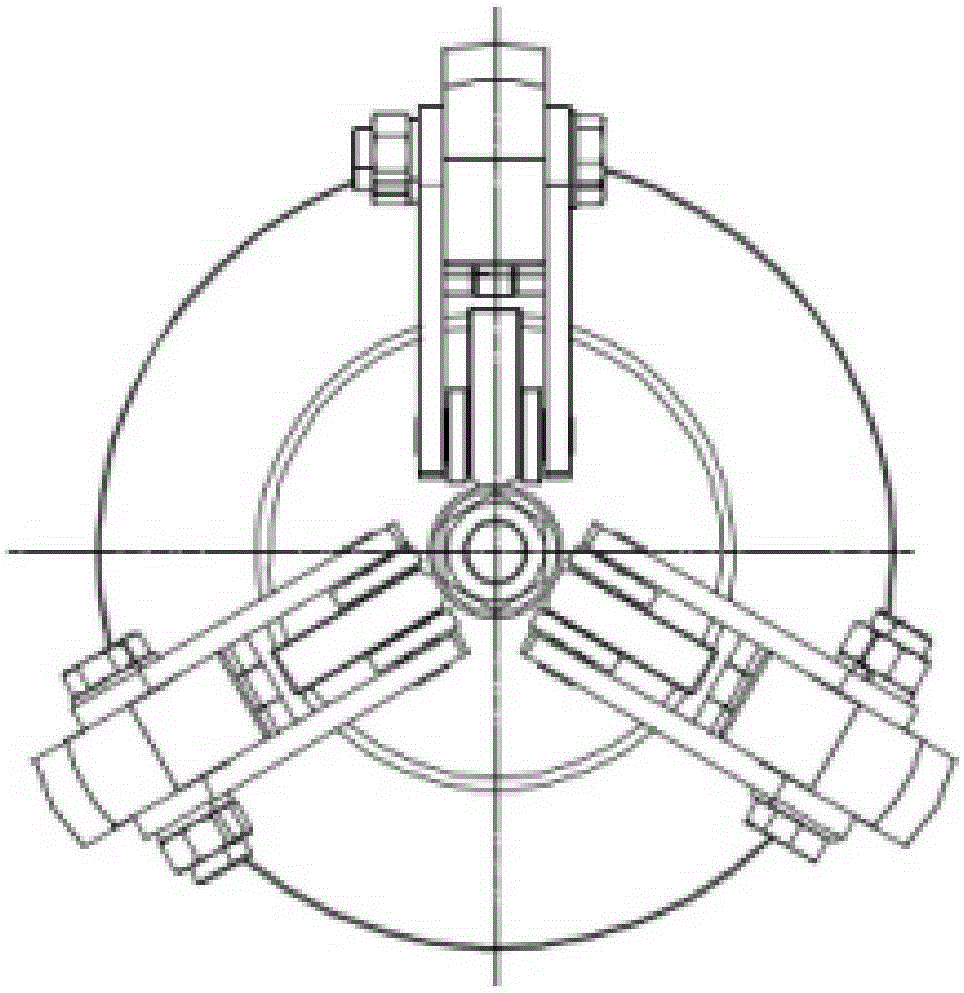

[0021] The triangular joint plate 2 is connected with the piston rod 1 of the pneumatic cylinder, and the triangular positioning frame 8 is fixed on the end of the pneumatic piston cylinder 1 through a positioning nut 10 . One end of the rib plate 7 is connected with the positioning claw base 4 through a cylindrical pin 6, and the two can rotate relatively. The two ends of the connecting frame 9 are respectively connected with the ribs 7 through pins 5 , and the positioning claws 11 are fixed on the connecting frame 9 and move along with the movement of the connecting frame 9 . The pneumatic piston rod 1 is connected with the pneumatic cylinder, and the opening and closing of the positioning claws are controlled through the telescopic movement of the pneumatic cylinder. 3 locating pawls 11 are evenly distributed on the circumference, as shown in Fig. figure 2 As shown, and the distance between two positioning claws is 120°. When the pneumatic cylinder drives the pneumatic p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com