Double-spindle automatic drilling and tapping machine

An automatic drilling, dual-spindle technology, applied in other manufacturing equipment/tools, metal processing, metal processing equipment, etc., can solve the problems of low work efficiency, poor drilling quality, easy breakage of drill bits, etc., to facilitate drilling and tapping processing. , the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

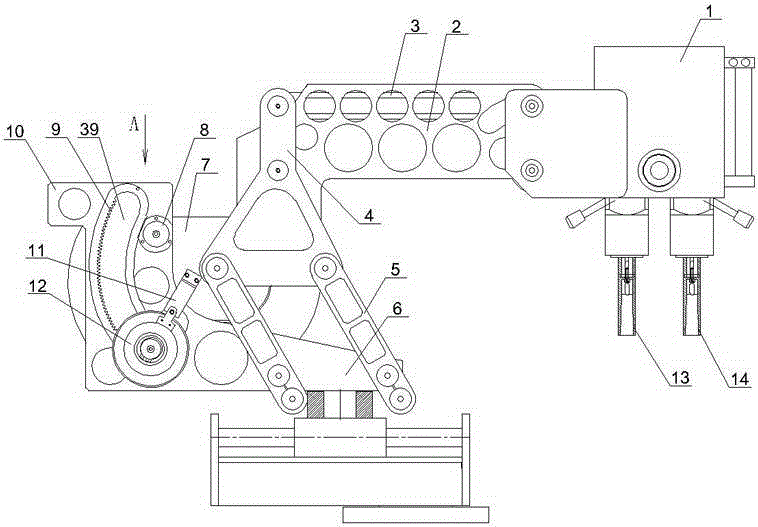

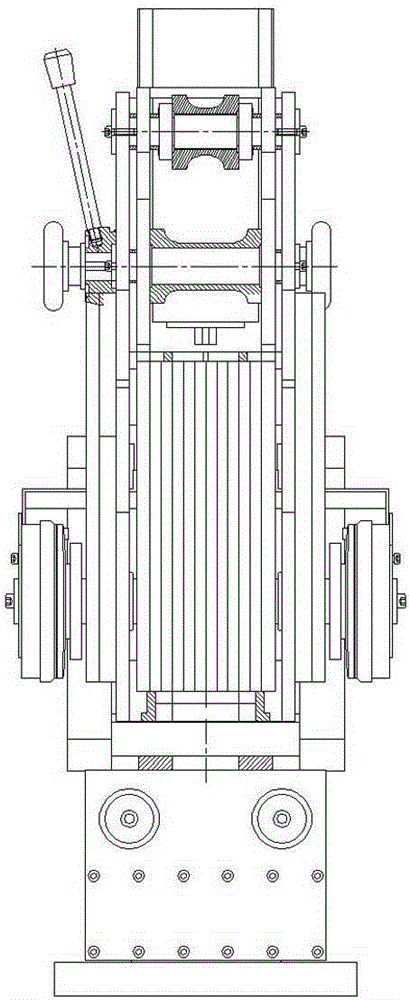

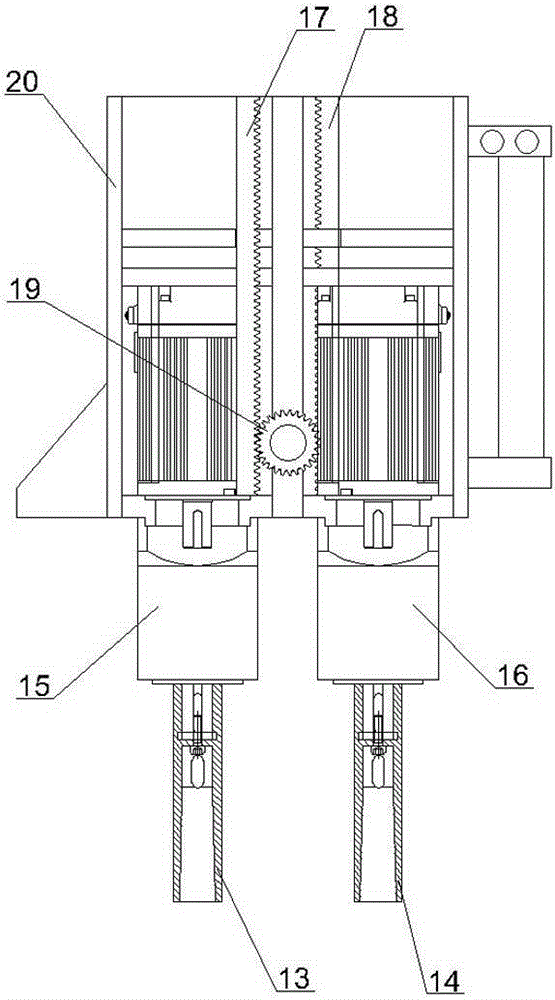

[0019] The accompanying drawings show the technical solution of the present invention and its embodiments, and the relevant details and working principles of the embodiments will be further described below in conjunction with the accompanying drawings.

[0020] As shown in the figure, the double-spindle automatic drilling and tapping machine of the present invention includes a drilling and tapping power head 1, and the drilling and tapping power head 1 has two main shafts, the first main shaft 14 is connected to the lower output end of the first gearbox 16, and the second The main shaft 13 is connected to the lower output end of the second gearbox 15. The first and second gearboxes are movable up and down in the power head casing 20. One side of the first gearbox 16 is fixedly connected to the first rack 18. The rack 18 is in transmission engagement with the first gear 28, and one side of the second gearbox 15 is fixedly connected to the second rack 17, and the second rack 17 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com