Ultrasonic composite sofa cloth

An ultrasonic wave and sofa release technology, applied in the field of fabrics, can solve problems such as poor embossing consistency, single surface structure and pattern, and affecting cutting.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

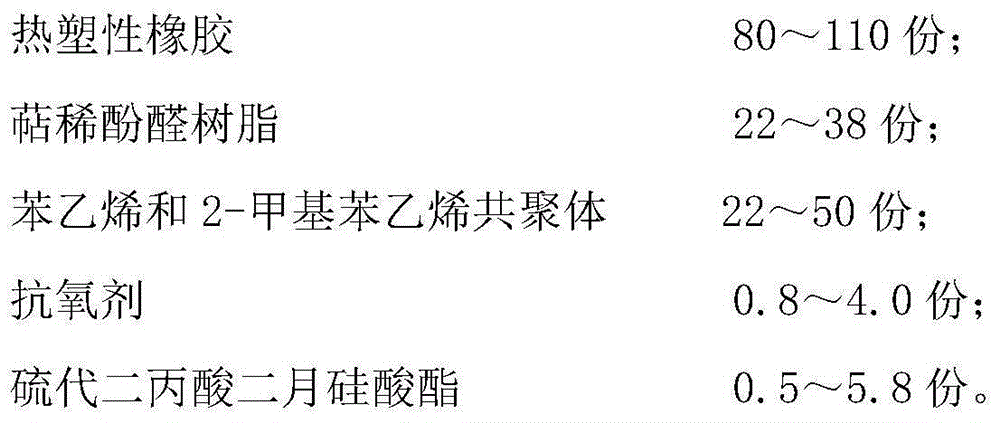

[0014] Embodiment 1: the components and parts by weight of the glue layer 3 are:

[0015]

Embodiment 2

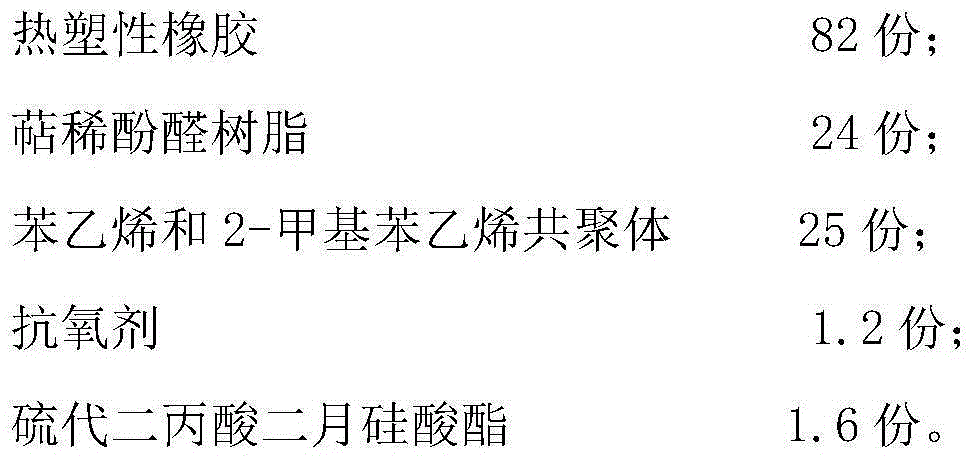

[0016] Embodiment 2: the components and parts by weight of the glue layer 3 are:

[0017]

Embodiment 3

[0018] Embodiment 3: the components and parts by weight of the glue layer 3 are:

[0019]

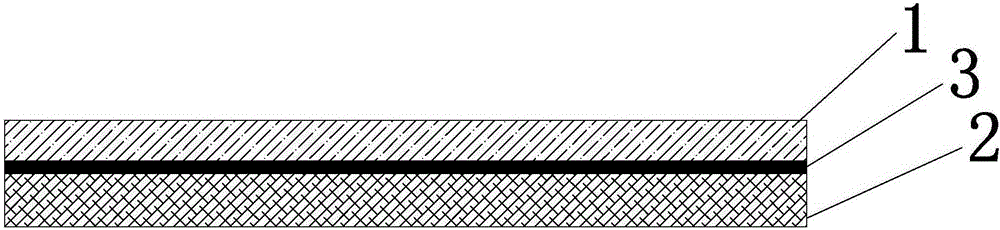

[0020] The warp-knitted super-soft and short-pile fleece 1 and the velvet base cloth 2 are subjected to various lines of embossing on the surface of the warp-knitted super-soft and short-pile fleece 1 by means of an ultrasonic embossing machine. The specific operation steps are as follows: position the cut warp-knitted super soft short plush cloth 1 on the ultrasonic equipment platform, use a semicircular die head, and the distance between the upper and lower dies is 0.6mm; the compressed air pressure is 3kg; and the delay time: 0.8s ; Holding time: 2.8s, start the ultrasonic equipment, make the warp-knitted super-soft short plush cloth 1 and the die head press together to form traces, and use the ultrasonic waves sent by the die mouth of the ultrasonic embossing machine to overlap along a certain path. The cloth is embossed, and the frequency of the ultrasonic wave is 26000-29000Hz....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com