Special-shaped guide hopper suitable for novel pressure vessel system

A pressure vessel and guide hopper technology, applied in the field of biomass pretreatment equipment, can solve the problems of occupying the discharge port and continuing to use the hopper

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with specific examples, without limiting the present invention.

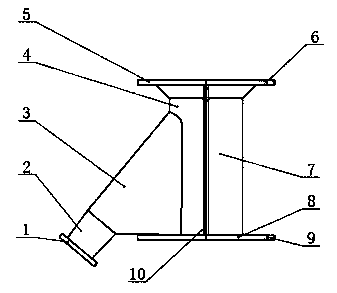

[0022] Firstly, drill blind holes and tap on the corresponding positions of the upper support cover and the lower flange of the new type discharge valve, each with a circle of ¢6mm screw holes evenly distributed.

[0023] The hopper parts made according to the design requirements are sent to the corresponding position from the large gap between the valve pillars on both sides, equipped with metal gaskets, and fastened with ¢6mm bolts until completely sealed and leak-free.

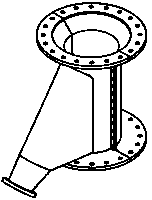

[0024] The special-shaped three-way hopper has one connection to the discharge port, one connection to the sealing block, and one connection to guide the spraying material, which is completely suitable for the unique special situation of the new type of discharge valve.

[0025] When the new pressure vessel system is sprayed, the sealing block descends rapidly, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com