a from alh 3 /mgcl 2 Extraction of α‑alh from nanocomplexes 3 powder method

A nano-composite and powder technology, applied in chemical instruments and methods, metal hydrides, inorganic chemistry, etc., can solve the problems of high equipment requirements, low reaction yield, environmental pollution, etc., and achieve low environmental pollution, smooth surface, The effect of large powder particle size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

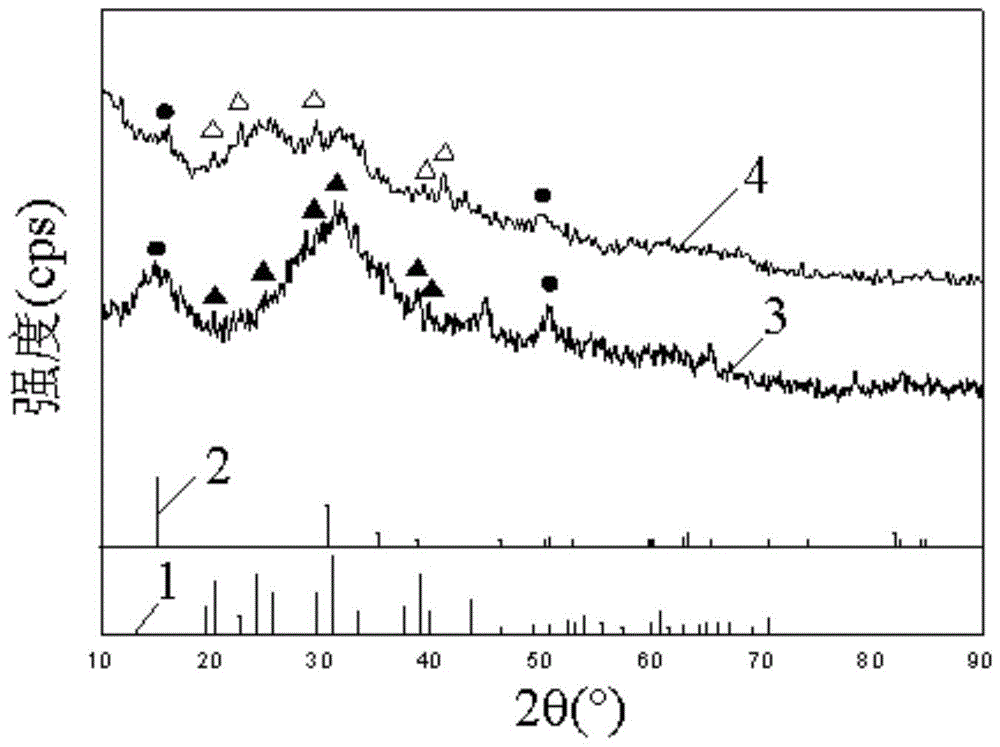

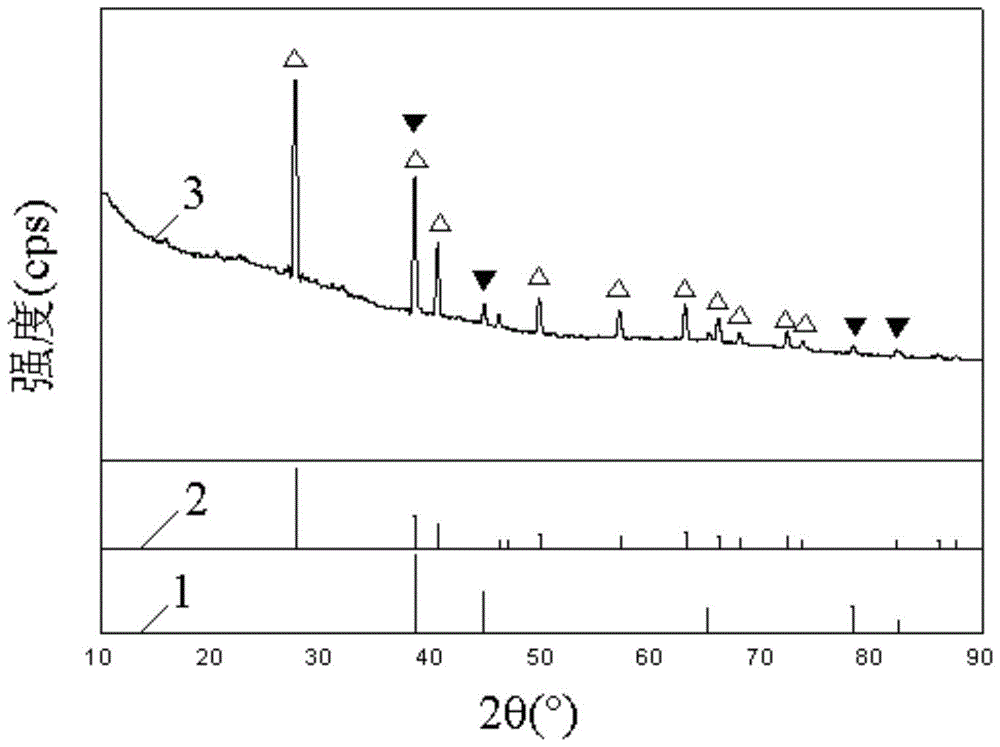

[0032] Specific implementation mode 1: This implementation mode is a kind of nano-AlH 3 Extraction of α-AlH from metal chlorides 3The powder method is done as follows:

[0033] 1. Nano-AlH 3 / Metal chloride is added to the solvent, and then stirred at a stirring speed of 60r / min to 100r / min for 10min to 90min to obtain a solid-phase metal salt and a liquid-phase AlH 3 Diethyl ether solution of ether compound;

[0034] Nano-AlH described in step 1 3 / metal chloride as AlH 3 / MgCl 2 Nanocomposite powder or AlH 3 / LiCl nanocomposite powder;

[0035] Nano-AlH described in step 1 3 The mass of / metal chloride and the volume ratio of solvent are (1g~3g): 50mL;

[0036] 2. Combine the metal salt in the solid phase and the AlH in the liquid phase 3 The ether solution of the ether compound is centrifuged at a centrifugal speed of 3000r / min to 12000r / min for 10min to 30min to remove the metal salt in the solid phase and obtain the AlH in the liquid phase. 3 Diethyl ether s...

specific Embodiment approach 2

[0047] Specific embodiment two: the difference between this embodiment and specific embodiment one is: AlH described in step one 3 / MgCl 2 Nanocomposite powders were prepared as follows:

[0048] ①. Put the magnesium powder with a particle size of 0.1mm to 2mm or the magnesium alloy powder with a particle size of 0.1mm to 2mm in the ball mill pot, put the ball into the ball at a ratio of (30 to 120): 1 by mass ratio of the ball to material, and place it in the ball mill. Ball milling at a speed of 250r / min to 400r / min for 15h to 20h under a hydrogen atmosphere to obtain nanocrystalline MgH with a grain size of 9nm to 11nm and a powder particle size of 1μm to 10μm 2 powder;

[0049] The magnesium alloy described in step ① is ZK60; the Mg content in the ZK60 is 93.5%, the Zn content is 6%, and the Zr content is 0.5%;

[0050] ②, ball milling, reaction: firstly, the nanocrystalline MgH with a grain size of 9nm to 11nm and a powder particle size of 2 Powder and AlCl 3 Mix the...

specific Embodiment approach 3

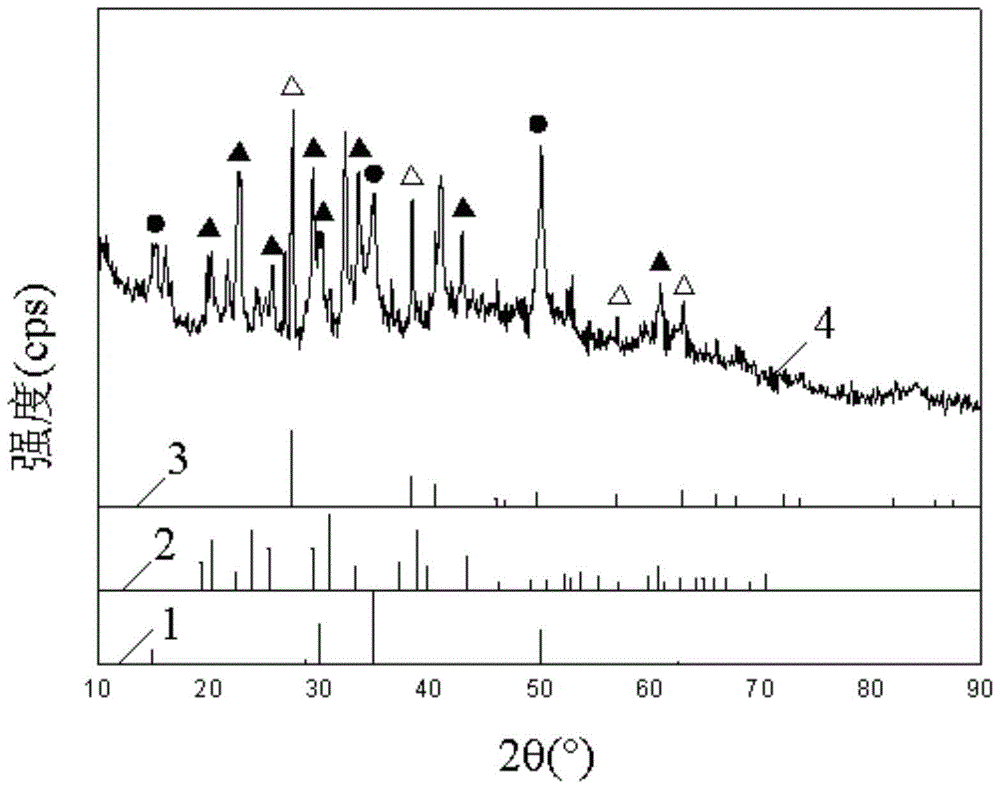

[0052] Specific embodiment three: the difference between this embodiment and specific embodiment one or two is: AlH described in step one 3 / LiCl nanocomposite powders were prepared as follows:

[0053] ①. Weigh LiAlH 4 , AlCl 3 and LiBH 4 ;

[0054] LiAlH described in step ① 4 with AlCl 3 The molar ratio is (2.8~3.2):1;

[0055] LiBH as described in step ① 4 with AlCl 3 The molar ratio is (2~10):1;

[0056] ②, weigh the LiAlH in step ① 4 , AlCl 3 and LiBH 4 were dissolved in three parts of ether to obtain LiAlH 4 Diethyl ether solution, AlCl 3 Diethyl ether solution and LiBH 4 ether solution;

[0057] LiAlH as described in step ② 4 LiAlH in ether solution 4 The molar ratio with ether is 1:(20~50);

[0058] AlCl described in step ② 3 AlCl in ether solution 3 The molar ratio with ether is 1:(20~50);

[0059] LiBH as described in step ② 4 LiBH in ether solution 4 The molar ratio with ether is 1:(20~50);

[0060] ③, LiAlH obtained in step ② 4 Diethyl ethe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com