Method for catalytically synthesizing 3,4'-dichlorodiphenyl ether by using microwaves

A technology of dichlorodiphenyl ether and microwave catalysis, applied in 3 fields, can solve the problems of Ullmann's application limitations, harsh reaction conditions, long reaction time, etc., and achieve the effect of easy operation, less side reactions and fast reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

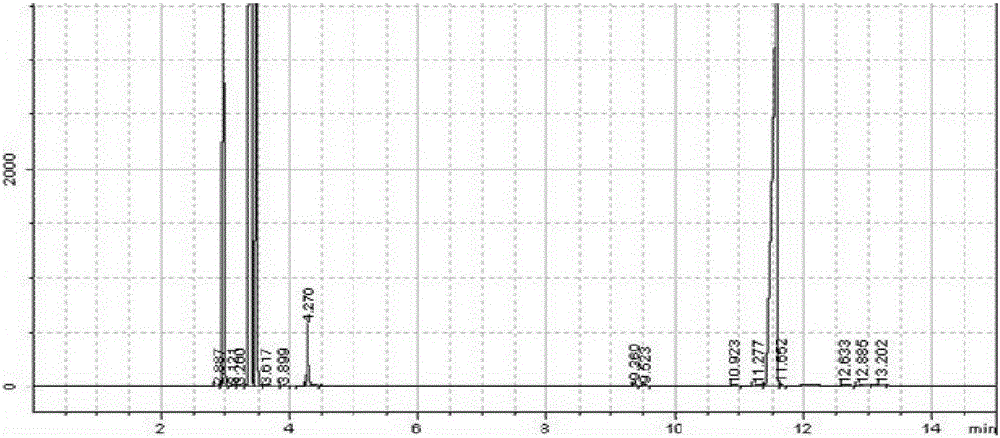

Examples

Embodiment 1

[0025] First prepare the organic solvent, the specific method is as follows:

[0026] (11) In a 100mL three-necked flask equipped with a reflux condenser, add 0.1mol of 1-methylimidazole, 0.1mol of bromobutane and 0.1mol of KPF 6 , stirred and reacted at 80°C for 3h;

[0027] (12) Cool to room temperature after the reaction, add 20-50mL of water, stir well and let it stand to separate the water phase;

[0028] (13) The separated ionic liquid is then repeatedly washed with distilled water until no halogen ions are detected with silver nitrate in the washing water;

[0029] (14) Vacuum drying at 120° C. for 4 hours to obtain an oily ionic liquid;

[0030] (15) Mix the ionic liquid and dipropylene glycol dimethyl ether in a mass ratio of 1:1 to 100 to obtain an organic solvent.

[0031] The ionic liquid in this example and dipropylene glycol dimethyl ether were mixed at a mass ratio of 1:1 to prepare an organic solvent.

[0032] Present embodiment prepares 3, the method for 4...

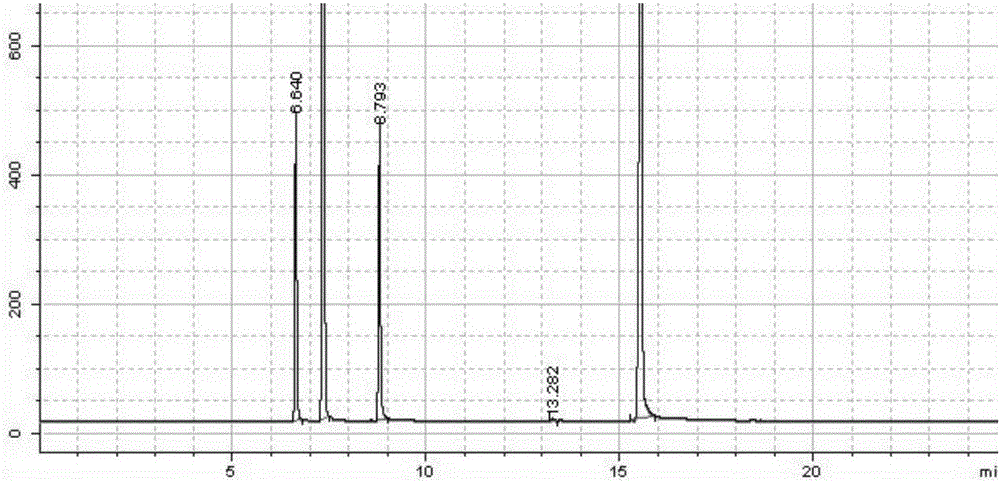

Embodiment 2

[0036] The ionic liquid of this example and dipropylene glycol methyl ethyl ether were mixed at a mass ratio of 1:20 to prepare an organic solvent.

[0037] Present embodiment prepares 3, the method for 4'-dichlorodiphenyl ether is as follows:

[0038] (1) m-dichlorobenzene, p-chlorophenol, alkali and organic solvent are mixed, add copper salt simultaneously as catalyzer; Described m-dichlorobenzene: p-chlorophenol: potassium carbonate alkali: the mol ratio of cuprous chloride salt is 6:1:1.2:0.01, the organic solvent accounts for 10% of the total material mass ratio;

[0039] (2) Under microwave catalysis, the above mixture was stirred and reacted for 2 hours at a power of 500W, and the reaction temperature was 60-110° C. under normal pressure. Stand to cool, filter, and rectify the filtrate under reduced pressure to collect a colorless transparent liquid, with a conversion rate of 99% and a yield of 93%.

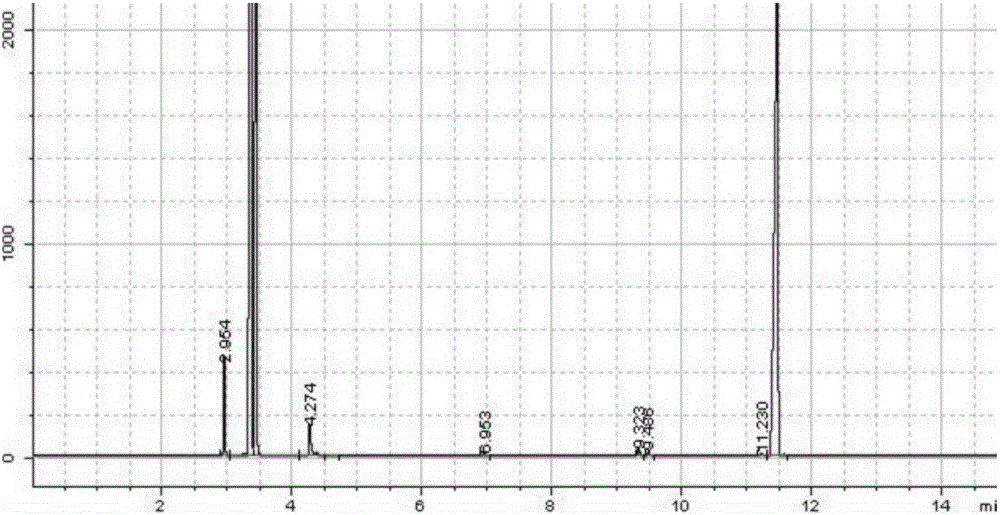

Embodiment 3

[0041] The ionic liquid of this example and dipropylene glycol methyl propyl ether were mixed at a mass ratio of 1:100 to prepare an organic solvent.

[0042] Present embodiment prepares 3, the method for 4'-dichlorodiphenyl ether is as follows:

[0043] (1) m-dichlorobenzene, p-chlorophenol, sodium hydroxide and organic solvent are mixed, and copper acetate is added as a catalyst; the m-dichlorobenzene: p-chlorophenol: alkali: the molar ratio of copper salt is 6:1 : 2: 0.1, the organic solvent accounts for 20% of the total material mass ratio;

[0044] (2) Under microwave catalysis, the above mixture was stirred and reacted for 2 hours at a power of 1000W, and the reaction temperature was 60-130° C. under normal pressure. Stand to cool, filter, and rectify the filtrate under reduced pressure to collect a colorless transparent liquid, with a conversion rate of 97% and a yield of 90%.

[0045] Other implementations are the same as in Example 1.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap