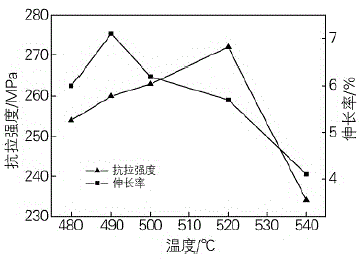

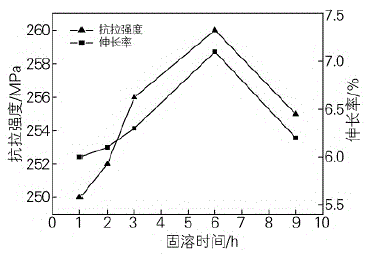

Solid solution treatment technology for improving mechanical property of 4032 aluminum alloy

A technology of solution treatment and aluminum alloy, applied in the field of solution treatment process to improve the mechanical properties of 4032 aluminum alloy, can solve the problems of reducing the yield, affecting the rolling process, reducing the mechanical properties of the alloy, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The test uses 4032 aluminum alloy as raw material, weighs a certain amount of 4032 aluminum alloy and puts it into a resistance crucible furnace for heating and melting, and performs rotary blowing and refining treatment on the melt, and then adds a certain amount of RE-Ba-Sb modifier into the solution , to stir the melt. Then after a period of heat preservation, it is poured into a metal mold preheated at 400°C. Among them, the rotary injection equipment XD-J-100BP degassing refiner. The specific process is: blowing high-purity argon gas (99.999%) with a pressure of 0.5MPa, the gas flow rate is 0.4m3 / h, the rotor speed is 400r / min, and the refining time is 15min.

[0012] The specific process of modification is to raise the temperature of the melt to a modification temperature of 760°C, add a modification agent, stir well, keep it warm for 60 minutes, then lower the temperature to 720°C, and cast directly without removing slag, so that the melt flows evenly and prehea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com