Dry-hang joint for external wall of fabricated building and prefabricated external wall with dry-hang joint

A kind of building exterior wall, prefabricated technology, applied in the direction of building, building components, building structure, etc., can solve the problem of difficult to ensure the effective position of steel bars, affecting the safety of building structure, paint peeling, etc., to achieve controllable and good building quality. Waterproof and anti-leakage function, the effect of avoiding falling off

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

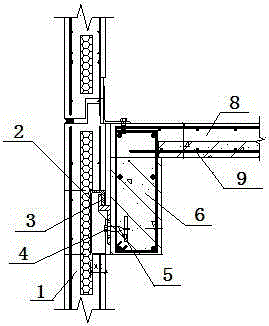

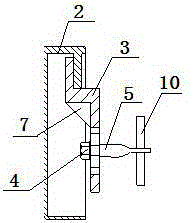

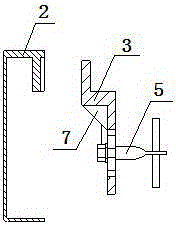

[0021] see Figure 1~Figure 3 , the dry-hanging node of the prefabricated building exterior wall of the present invention includes a pre-embedded box 2 embedded in the prefabricated exterior wall panel 1, a hook seat 3, and a connecting bolt 4, and the embedded box is open toward the side of the hook seat. The hook seat 3 passes through the side opening of the embedded box to support the entire prefabricated outer wall panel. The above-mentioned building body includes prefabricated beams 6 or shear walls. The open side of the embedded box 2 is set in the same vertical plane as the inner side of the prefabricated exterior wall panel.

[0022] The upper part of the above-mentioned hook seat 3 is bent forward and upward to protrude with a bending part, and the side of the embedded box is provided with a positioning baffle that partially blocks the upper part of the opening, and the bending part of the hook seat passes through After the opening of the embedded box 2 and the posi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com