Construction Method of Double Shear Wall Formwork Support Formwork at Deformation Joints

A construction method and deformation joint technology, which is applied in the direction of the formwork/formwork/work frame, the joints of the formwork/formwork/work frame, walls, etc., and can solve the problem that the filling materials such as benzene boards cannot be removed or the removal is not clean and time-consuming Problems such as filling materials such as benzene board and affecting the structure and function of deformation joints have been solved, so as to achieve the effect that the overall formwork system supported by airbags is not easy to deform, avoid residual garbage, and the overall formwork system supported by airbags is stable

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0059] The technical solutions of the present invention will be described in detail below through specific examples.

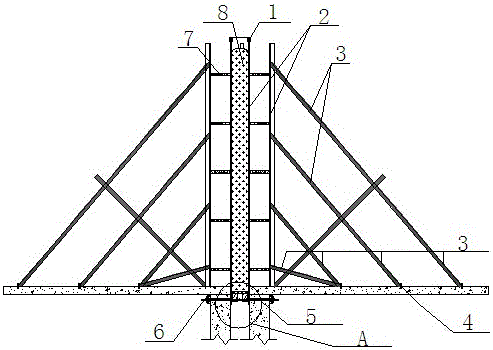

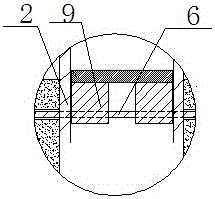

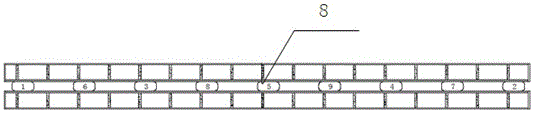

[0060] The construction method of the double shear wall formwork formwork at the deformation joints of the present invention has the following steps: construction preparation → setting out and positioning → production and installation of the formwork at the deformation joints and the airbag bracket platform → production and installation of steel bars for the shear walls → concrete limit Strip installation→wall base cleaning→inside (away from the deformation joint side) and floor formwork installation→outside (close to the deformation joint side) overall formwork fabrication and installation→high-pressure airbag placement→high-pressure airbag pressurization→shear wall head formwork installation → Fabrication and installation of temporary cover plates for formwork at deformation joints → Concrete pouring and maintenance → Deflation and removal of high-pressure ai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com