Top entry bellows trunnion ball valve

A technology for fixing ball valves and bellows, applied in valve devices, cocks including cut-off devices, engine components, etc., can solve the problems of leakage, many leakage points, complicated assembly and maintenance, etc., and achieve the effect of reducing manufacturing cost and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

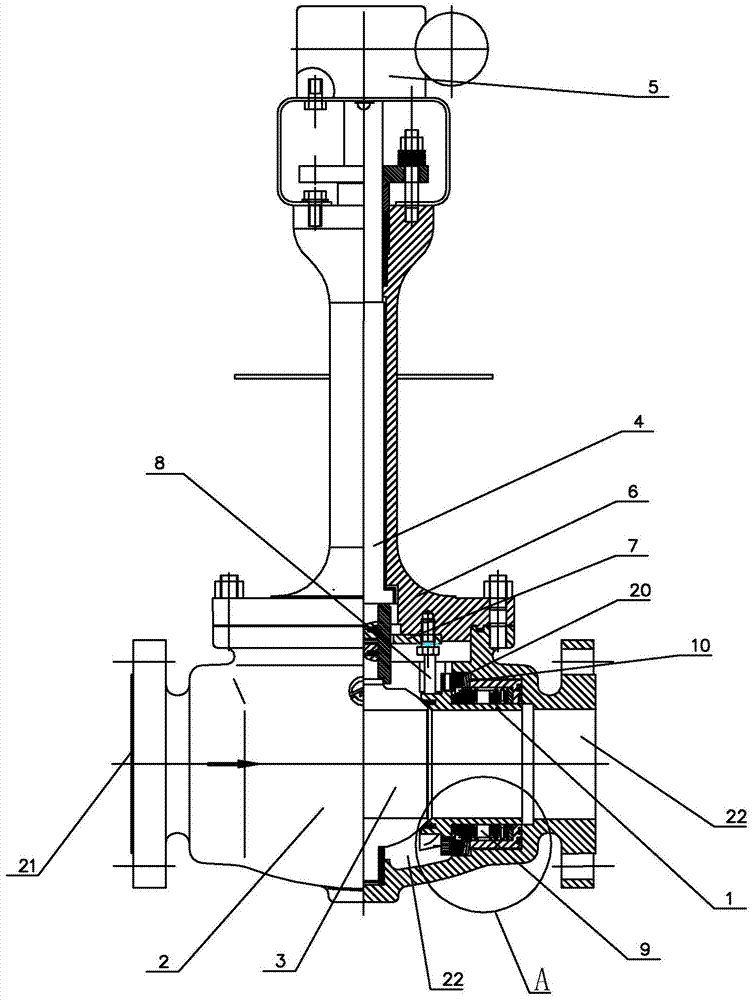

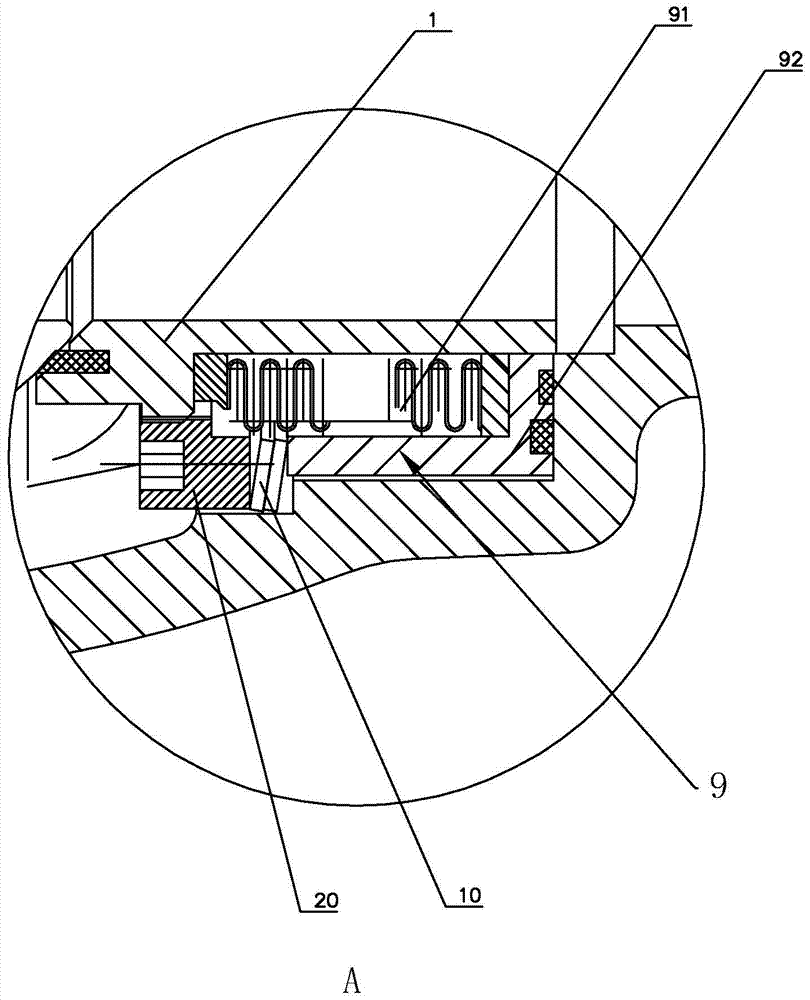

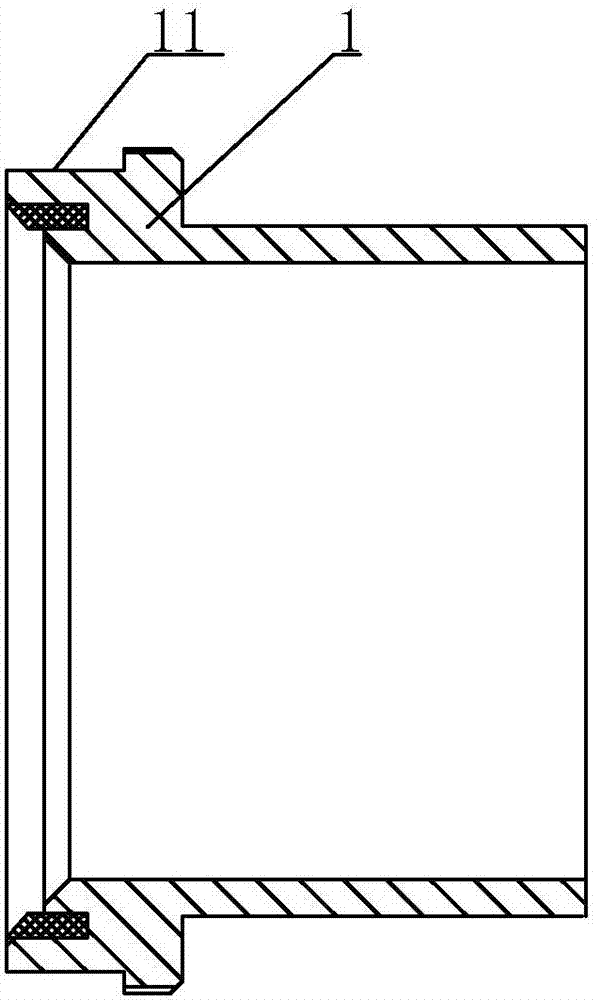

[0019] Refer to attached Figure 1 to Figure 5 A top-entry bellows fixed ball valve of the present invention will be further described in detail.

[0020] A top-entry bellows fixed ball valve, including a valve seat 1, a valve body 2, a valve ball 3, a valve stem 4, a handle 5 and a valve cover 6, the valve body 2 is provided with an inflow channel 21, an outflow channel 22 and a communication channel The valve cavity 23 of the inflow channel 21 and the outflow channel 22 (when the ball valve is used in a normal temperature or high temperature environment, the inflow channel and the outflow channel can be interchanged), the valve cavity 23 is provided with a valve ball 3, the valve stem 4 and the valve ball 3 Fixed connection, sealing packing is installed between the valve stem 4 and the valve cover 6, the end surface of the valve cover 6 facing the valve body 2 is fixedly connected with a support plate 7, and the valve stem 4 passes through the support plate 7 and is fixed to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com