Refrigerant supercooling structure for air-conditioner and central air-conditioner

A refrigerant and supercooling technology, applied in refrigerators, refrigeration components, refrigeration and liquefaction, etc., can solve the problems of increased device volume, poor system performance, and high cost, and achieve good supercooling effect, reasonable device structure, and low cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

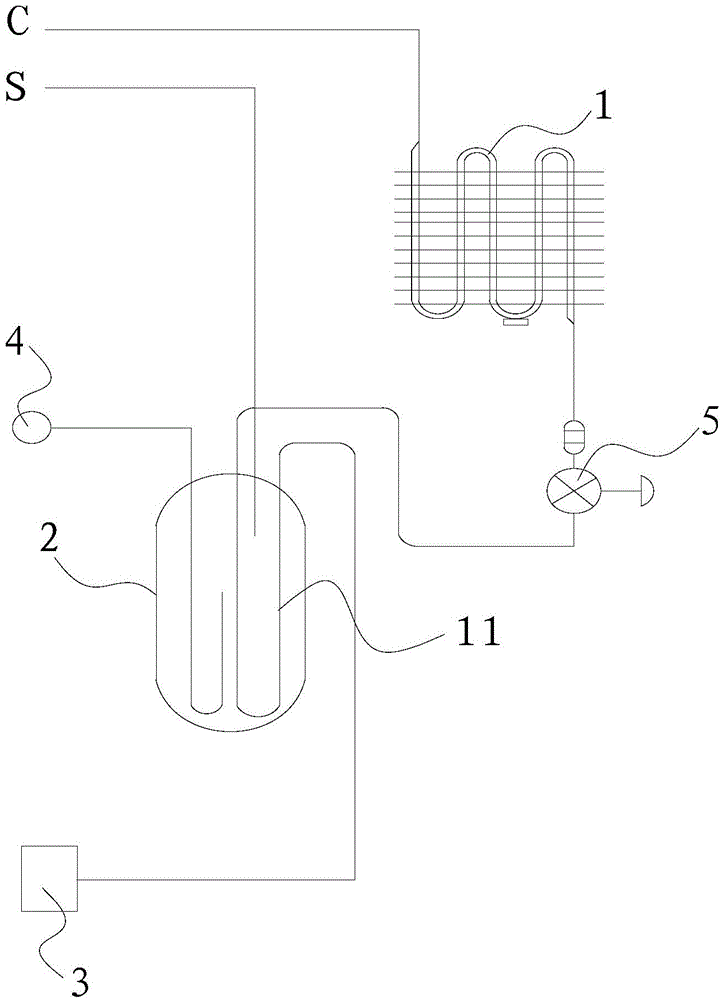

[0025] This preferred embodiment provides a refrigerant supercooling structure for an air conditioner. Such as figure 1 As shown, the subcooling structure includes a condenser 1 , a gas-liquid separator 2 , an indoor unit 3 and a compressor 4 , wherein the gas-liquid separator 2 is connected to the compressor 4 .

[0026] Specifically, one end of the pipeline 11 is connected to the outlet of the condenser 1 , and the other end is connected to the inlet of the indoor unit 3 , and the pipeline 11 at least partially passes through the interior of the gas-liquid separator 2 . An electronic expansion valve 5 is arranged on the pipeline 11 between the outlet end of the condenser 1 and the gas-liquid separator 2 .

[0027] The evaporator is connected to the gas-liquid separator 2 through the S pipe of the four-way valve, and the gas-liquid mixed state refrigerant discharged from the evaporator is separated through the gas-liquid separator 2; the separated gaseous refrigerant will be...

Embodiment 2

[0033] This preferred embodiment provides a refrigerant subcooling structure for air conditioners, the structure of which is basically the same as that of the first preferred embodiment. In the subcooling structure, one end of the pipeline is connected to the outlet end of the condenser, and the other end is connected to the inlet end of the indoor unit, and the pipeline at least partially passes through the interior of the gas-liquid separator. The gas-liquid separator is used to separate the refrigerant in the gas-liquid mixed state discharged from the evaporator, and send the separated gas refrigerant to the compressor; the gas refrigerant is condensed by the condenser to form a refrigerant liquid with a lower temperature, and the refrigerant liquid enters the gas through the pipeline. The heat exchange is carried out in the liquid separator, and the temperature of the refrigerant liquid is further lowered and then enters the inlet port of the indoor unit.

[0034] The diff...

Embodiment 3

[0037] This preferred embodiment provides a central air conditioner. The central air conditioner includes the refrigerant subcooling structure for air conditioners as described in the preferred embodiment 1 or 2. The evaporator is connected to the inlet pipe of the gas-liquid separator through the S pipe of the four-way valve, and the outlet pipe of the gas-liquid separator is connected to the compressor; the C pipe of the four-way valve is connected to the inlet port of the condenser.

[0038] After the subcooling treatment in the gas-liquid separator, the temperature of the refrigerant liquid is lower. After a long pipeline, what enters the indoor unit is a real low-temperature and high-pressure refrigerant liquid, so the central air conditioner has better cooling and heating effects, low energy consumption, low operating costs, and can cover a larger space.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com