Portable flue gas sampling device

A sampling device and portable technology, applied in the field of portable flue gas sampling devices, can solve the problems of difficult transportation distance, inconvenient use, changes in flue gas components, etc., and achieve the effects of saving equipment manufacturing costs, reducing total volume, and being convenient to carry.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

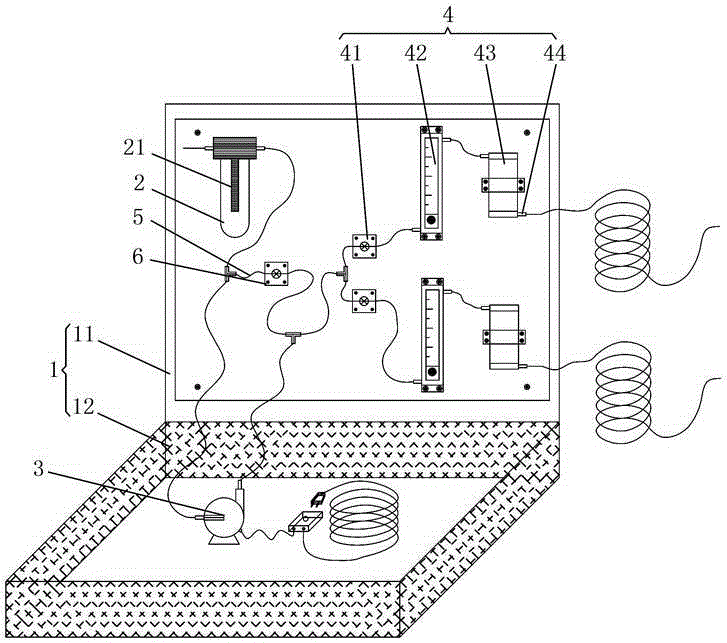

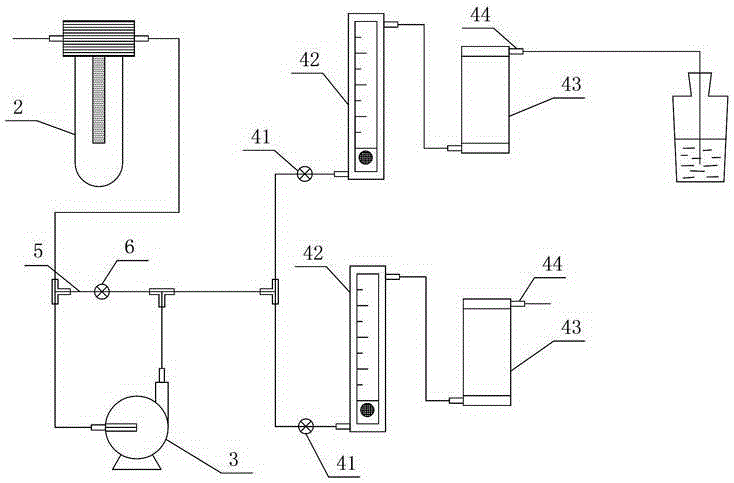

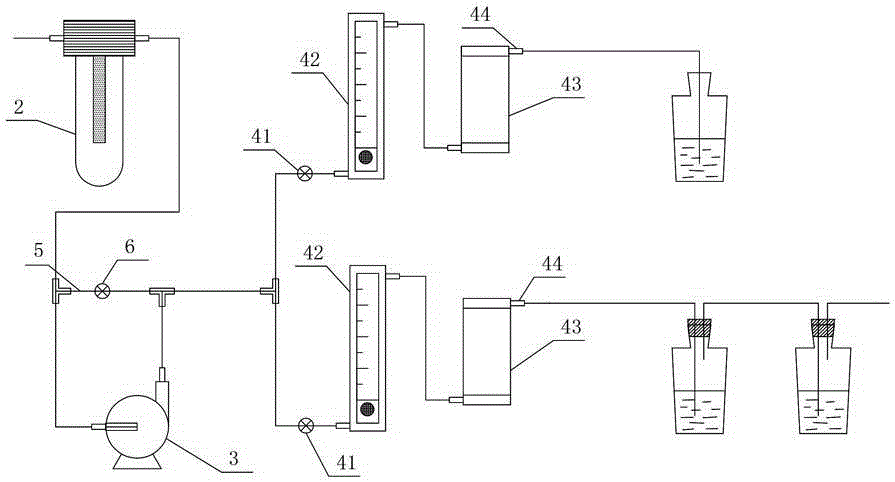

[0025] figure 1 It shows an embodiment of a portable flue gas sampling device of the present invention, which includes a box body 1 and a flue gas filtering device 2 installed in the box body 1, a sampling pump 3 and more than two sampling rate precision control lines 4 , the flue gas filter device 2 is connected to the input end of the sampling pump 3, and more than two sampling rate precise control lines 4 are connected in parallel to the output end of the sampling pump 3. In this embodiment, there are two sampling rate fine control lines 4. The portable flue gas sampling device of the present invention is equipped with only one sampling pump 3, which can provide more than two streams of flue gas sampling, solves the problem of sampling fluoride and sulfur dioxide at the same time, and ensures more flue gas components under the same working condition The determination of; simultaneously saved the equipment manufacturing cost, reduced the total volume of equipment, total mass...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com