Small celestial body integrated sampler with grinding and clamping functions

A technology for samplers and small celestial bodies, applied in sampling devices and other directions, can solve the problems of sample suspension or scattering, difficulty in sampling collection and packaging, etc., to avoid sample damage, realize controllable clamping force design, and solve lofting problems. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be described below in conjunction with the drawings.

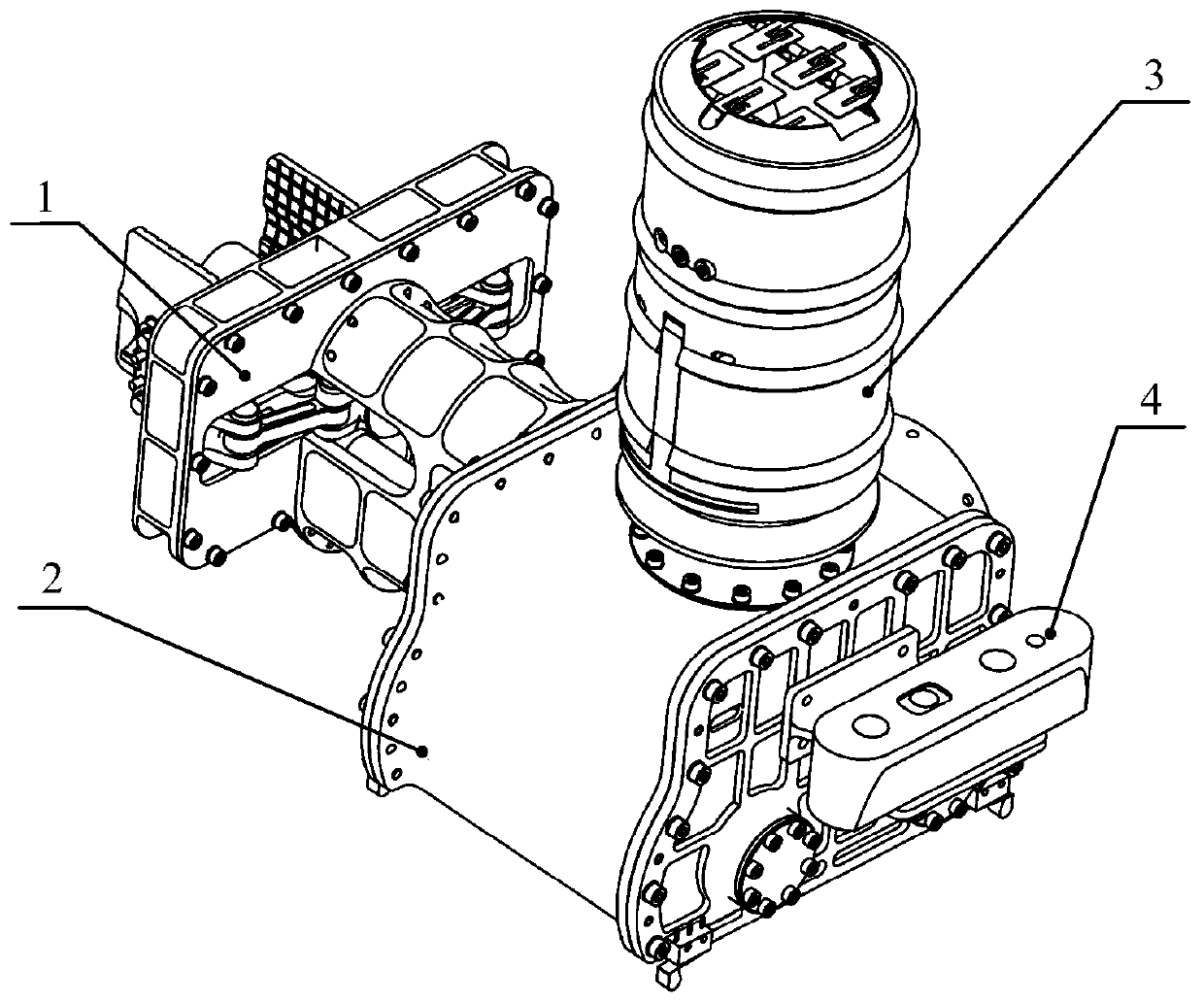

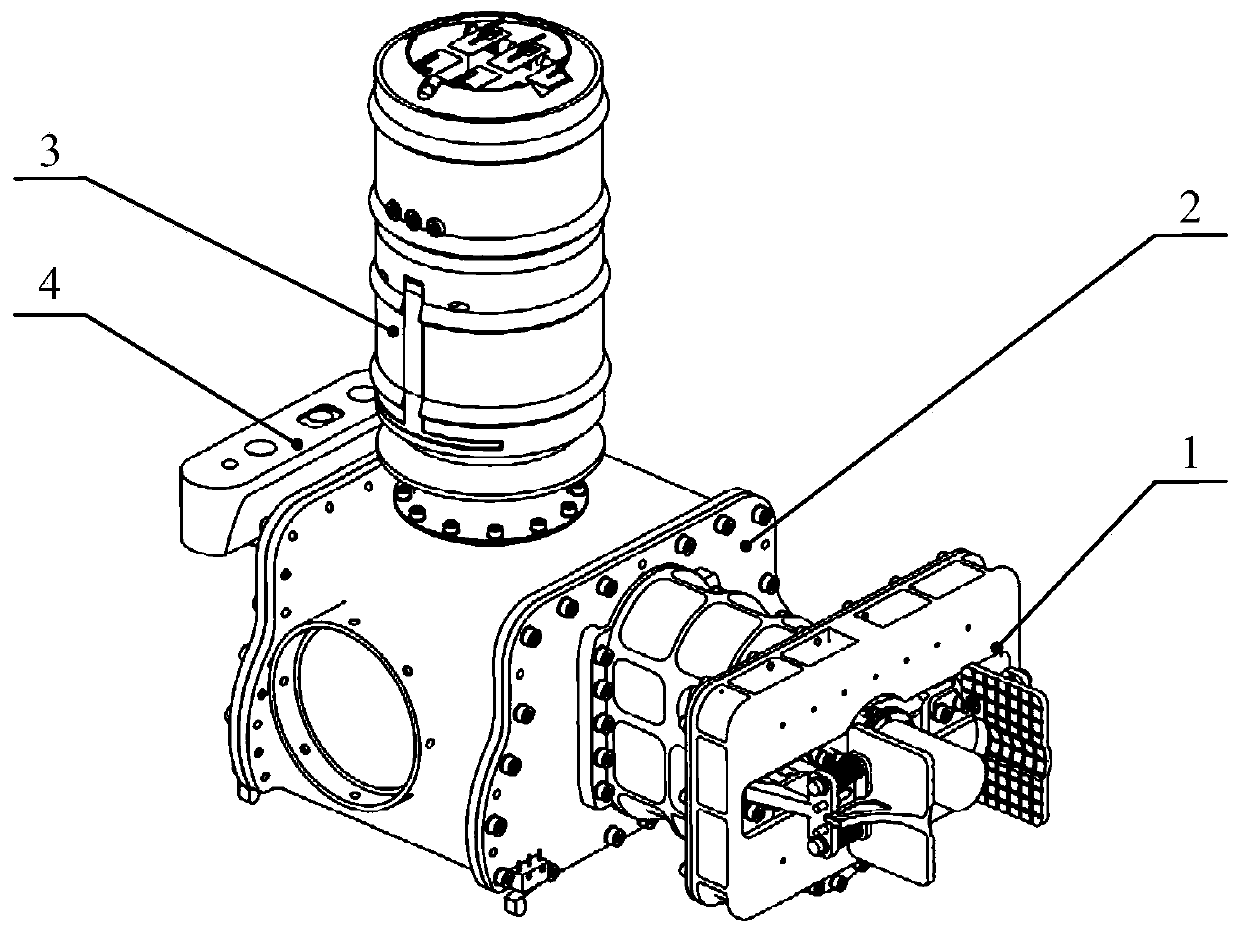

[0035] Such as Figure 1~2 As shown, an integrated small celestial body sampler with grinding and clamping functions includes a clamping sampler 1, a grinding sampler 2, a sample packaging container 3, and a depth camera 4. The clamping sampler 1, the sample packaging container 3, and the depth camera 4 are respectively installed on the grinding sampler 2. The depth camera 4 performs preliminary topography judgments, and the sample packaging container 3 is used to store the obtained samples.

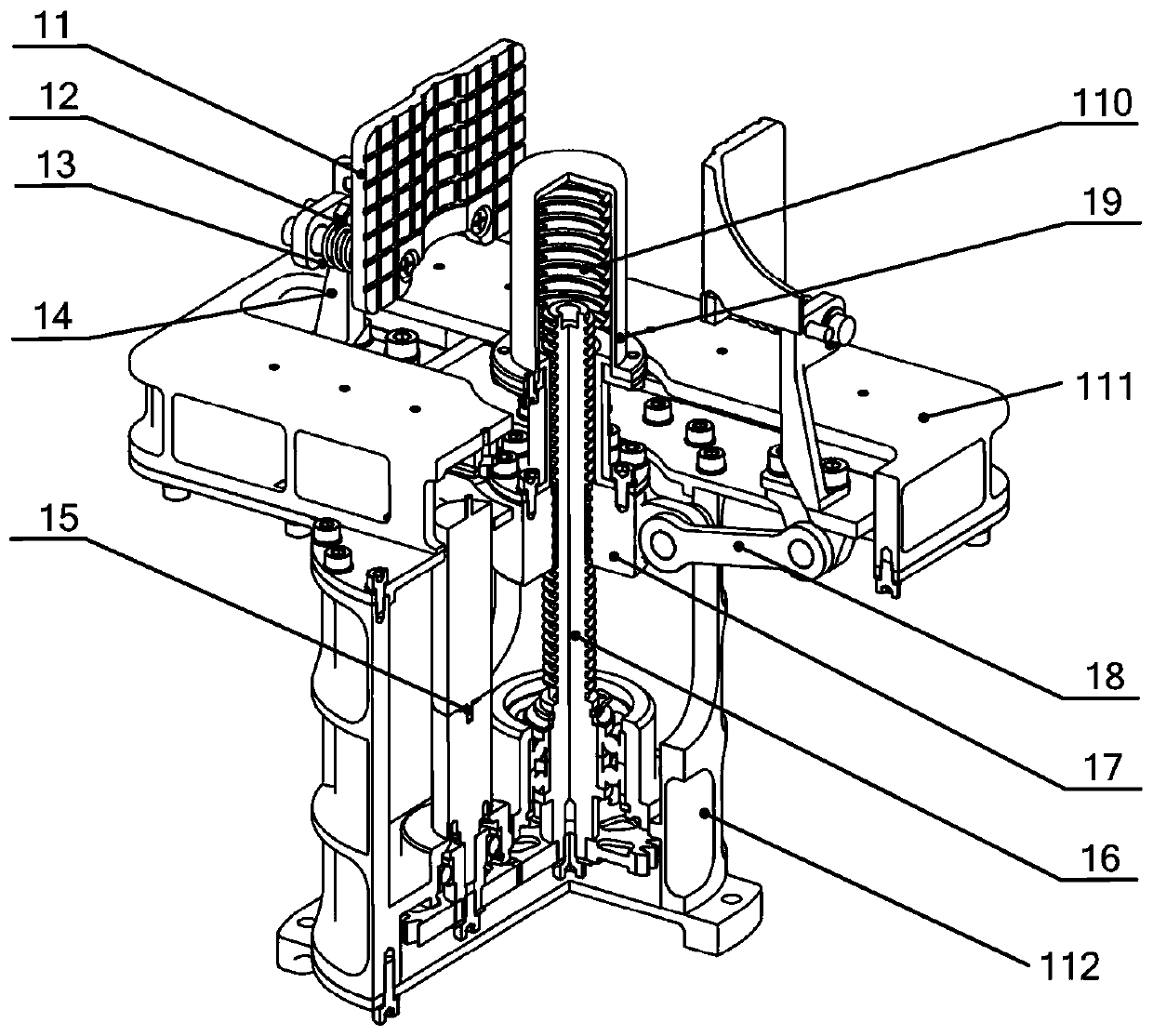

[0036] Such as image 3 As shown, the clamping sampler 1 includes a clamping claw 11, a clamping contact switch 12, a clamping spring 13, a clamping holder 14, a clamping motor 15, a ball screw 16, a screw nut 17, a connecting rod 18. Stake out push rod 19, push rod spring 110, clamp sampler housing 112, and guide rail 111.

[0037] The clamping motor 15 is installed in the clamping sampler housing 112. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com