Semi-automatic sperm stainer

A semi-automatic dyeing machine technology, applied in the field of sperm staining machine, can solve the problems of high price, difficult standardization of sperm staining, difficult to guarantee the staining effect, etc., and achieve the effect of easy mixing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

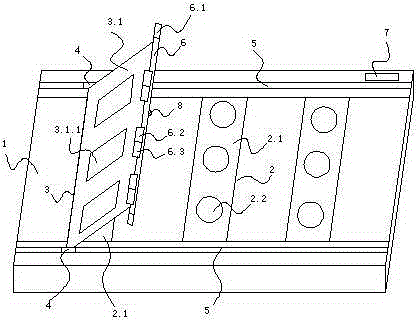

[0014] Embodiment 1: a semi-automatic sperm staining instrument, comprising a rectangular base 1, 3 staining solution containers 2 arranged side by side along the long sides at intervals on the base 1, and a pad dyeing device 3 arranged above the base 1, said The pressure dyeing device 3 includes a press plate 3.1 whose long side is horizontal to the short side of the base 1, and 3 sperm-coated glass sheets 3.1.1 arranged on the press plate 3.1. The two ends of the lower long side of the press plate 3.1 are hinged with a sliding connection device 4, so that The pressing plate 3.1 can be turned up and down and can slide back and forth along the long side of the base 1 . The staining solution container 2 includes a strip-shaped base 2.1 fixedly connected to the base 1 and three bowl-shaped liquid storage containers 2.2 arranged on the strip-shaped base 2.1. The bowl-shaped liquid storage containers 2.2 are plastic elastomers. The positions of the sperm-coated glass slide 3.1.1 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com