Electrochromic smart window and encapsulation method thereof

A technology of electrochromism and encapsulation method, which is applied in nonlinear optics, instruments, optics, etc., can solve problems such as insufficient flatness, and achieve the effect of uniform coloring, uniform distribution, and good sealing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

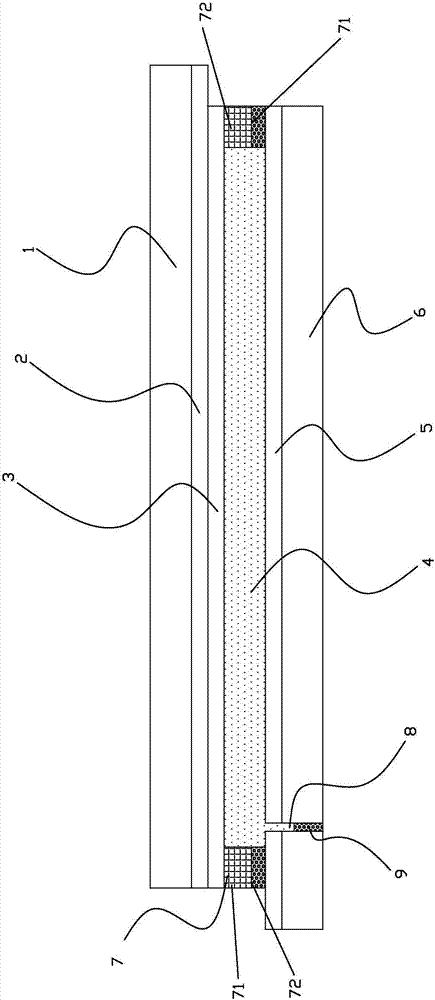

Image

Examples

Embodiment 1

[0031] The electrochromic smart window encapsulation method comprises the following steps:

[0032] 1) Around the second transparent conductive layer, according to the contour shape of the electrochromic smart window, use bisphenol A diglycidyl methacrylate (Bis-GMA), nano-SiO2, and initiator to print a raised window through screen printing. Encapsulation frame, the surrounding width is set at 200mm;

[0033] 2) Paste a thermoplastic film on the cured packaging frame, the thickness of the packaging frame is 5mm, the thickness of the thermoplastic film is 25mm, and the width of both is 4mm;

[0034] 3) Put the smart window in the heat sealing machine, seal the thermoplastic film by hot pressing, the temperature is 100 degrees, and the hot pressing time is 15s, put the electrochromic smart window in the heat sealing machine, and seal the electric film by hot pressing. The color-changing smart window is well sealed;

[0035] 4) Electrolyte is injected through the through hole, ...

Embodiment 2

[0037] The electrochromic smart window encapsulation method comprises the following steps:

[0038] 1) Around the second transparent conductive layer, according to the contour shape of the electrochromic smart window, use bisphenol A diglycidyl methacrylate (Bis-GMA), nano-SiO2, and initiator to print a raised window through screen printing. Encapsulation frame, the surrounding width is set at 260mm;

[0039] 2) Paste a thermoplastic film on the cured packaging frame, the thickness of the packaging frame is 1mm, the thickness of the thermoplastic film is 25mm, and the width of both is 4mm;

[0040] 3) Put the smart window in the heat sealing machine, seal the thermoplastic film by hot pressing, the temperature is 130 degrees, and the hot pressing time is 10s, put the electrochromic smart window in the heat sealing machine, and seal the electric film by hot pressing. The color-changing smart window is well sealed;

[0041] 4) Electrolyte is injected through the through hole, ...

Embodiment 3

[0043] The electrochromic smart window encapsulation method comprises the following steps:

[0044] 1) Around the second transparent conductive layer, according to the contour shape of the electrochromic smart window, use bisphenol A diglycidyl methacrylate (Bis-GMA), nano-SiO2, and initiator to print a raised window through screen printing. Encapsulation frame, the surrounding width is set at 310mm;

[0045]2) Paste a thermoplastic film on the cured packaging frame, the thickness of the packaging frame is 3mm, the thickness of the thermoplastic film is 25mm, and the width of both is 4mm;

[0046] 3) Put the smart window in the heat sealing machine, seal the thermoplastic film by hot pressing, the temperature is 125 degrees, and the hot pressing time is 12s, put the electrochromic smart window in the heat sealing machine, and seal the electric film by hot pressing. The color-changing smart window is well sealed;

[0047] 4) Electrolyte is injected through the through hole, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com