Gradually varied inertia liquid filling execution mechanism and method for controlling high-accuracy attitude of spacecraft

An actuator and filling valve technology, applied in attitude control and other directions, can solve the problems of spacecraft fuel quality redundancy, increased mutual influence and interference, and space waste.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

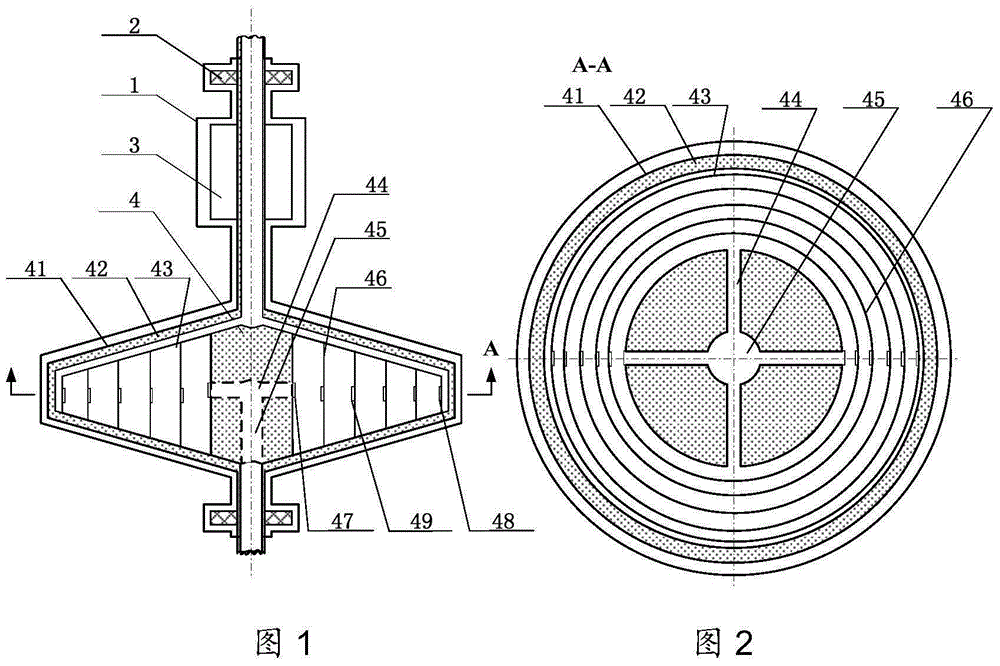

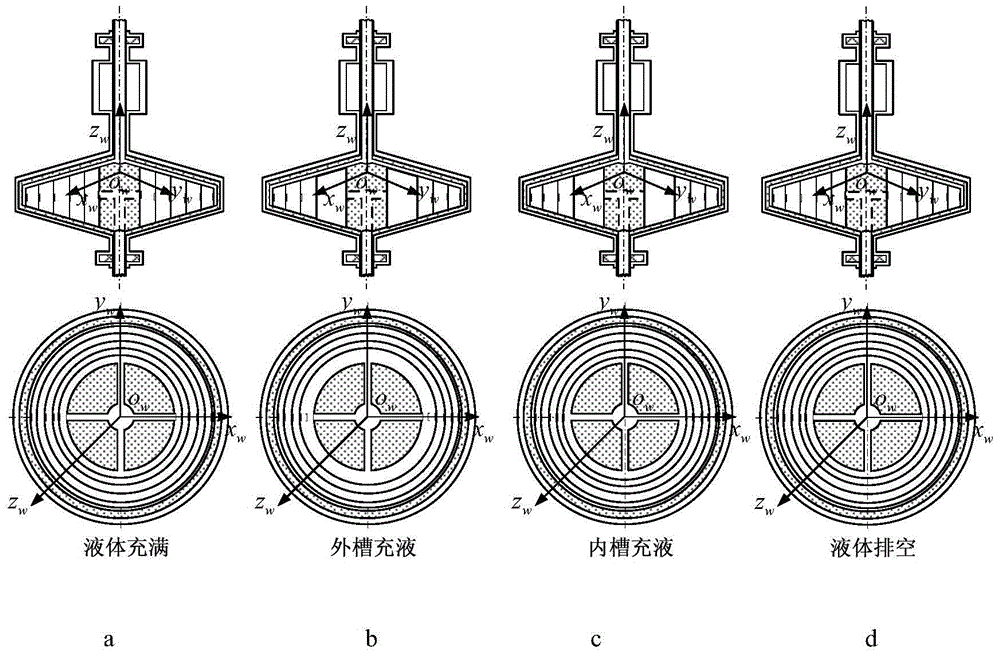

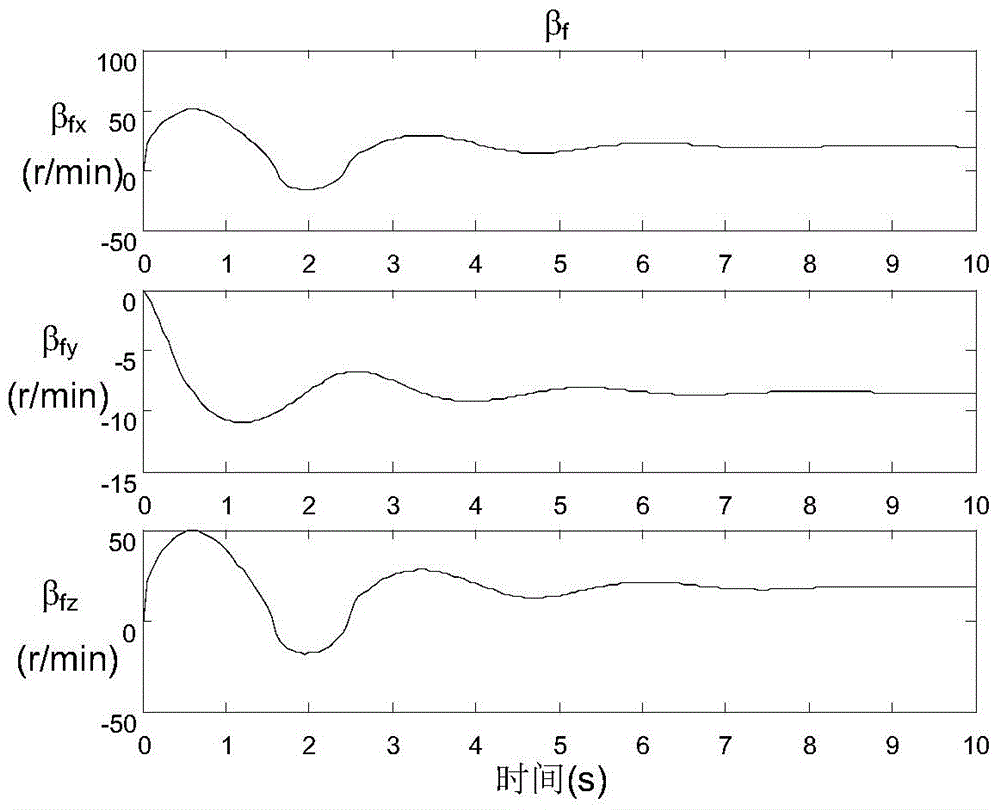

[0028]In order to improve the execution ability of the attitude control actuator during the attitude control process, increase the coverage of the output torque, and reduce the problems of dynamic imbalance and excessive resistance caused by structural and process design problems when the rotating parts rotate at high frequencies, combined with The structure and working characteristics of the air injection mechanism and the angular momentum exchange actuator, the present invention proposes a new type of actuator that uses liquid filling to adjust the moment of inertia of the flywheel, and improves the configuration of the angular momentum exchange actuator and the inherent concept of the rotor. Continuously change the liquid filling ratio of the liquid working medium to realize the continuous change of the moment of inertia. According to the requirements of different attitude stability and attitude maneuverability, the moment of inertia of the actuator can be adjusted independen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com