Orientation press method of neodymium-iron-boron magnet

A NdFeB, magnet technology, used in magnetic objects, inductor/transformer/magnet manufacturing, magnetic materials, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0059] The present invention also provides a preparation method of an NdFeB magnet, comprising the following steps:

[0060] 1) Sintering the NdFeB magnet compact described in any one of the above technical solutions to obtain the NdFeB magnet blank;

[0061] 2) Slitting the NdFeB magnet blank obtained in the above steps to obtain the finished NdFeB magnet.

[0062] In the present invention, firstly, the NdFeB magnet compact described in any one of the above technical solutions is sintered to obtain a NdFeB magnet blank. In the present invention, firstly, the raw materials for preparing NdFeB magnets are sintered for the first time to obtain a primary sintered body; the present invention has no special limitation on the temperature of the sintering, and the temperature of sintered NdFeB magnets well known to those skilled in the art is i.e. Yes, the present invention is preferably 1000-1100°C, more preferably 1020-1050°C; the present invention has no special limitation on the...

Embodiment 1

[0071] Prepare a sintered NdFeB magnet A with a finished product size of 20mm×4mm×9mm

[0072] Micropowder preparation: the above-mentioned NdFeB raw material A is smelted, crushed and pulverized to obtain NdFeB raw material micropowder with a particle size of 4.0 μm.

[0073] Orientation pressing: uniformly mix the NdFeB fine powder and the lubricant methyl caprate according to the mass ratio of 1:0.0015, and after mixing for 90 minutes, a mixture of NdFeB fine powder is obtained;

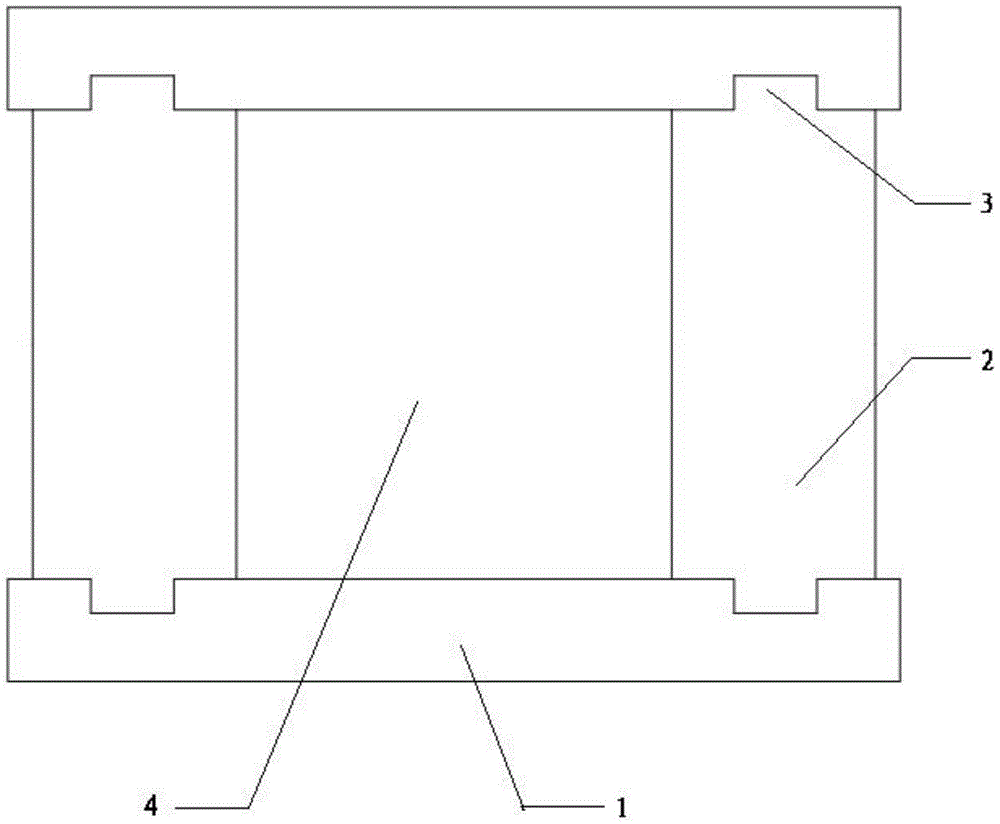

[0074] Mold assembly: take two (orientation plate) large side plates 1 prepared by non-magnetic materials, and two small side plates (non-orientation plates) 2 prepared by non-magnetic materials, and the two small side plates are in the same position as the large The interface of the side plate combination is provided with a square-shaped clamping protrusion 3, the center line of the clamping protrusion coincides with the center line of the joint interface, and the height of the clamping protrusio...

Embodiment 2

[0082] Prepare a sintered NdFeB magnet B with a finished product size of 13mm×4mm×9mm

[0083] Micropowder preparation: the above-mentioned NdFeB raw material B was smelted, crushed and pulverized to obtain NdFeB raw material micropowder with a particle size of 4.0 μm.

[0084] Orientation pressing: uniformly mix NdFeB fine powder and lubricant n-hexane according to the mass ratio of 1:0.003, and after mixing for 100 minutes, a mixture of NdFeB fine powder is obtained;

[0085] Mold assembly: according to the method of Example 1, the height of the clamping protrusion is 7mm, and a mold with a molding height of 14mm and an overall size of 45mm×14mm×39.5mm is obtained.

[0086] Then add the NdFeB fine powder mixture into the mold, put it into a small press machine produced by Taiyuan Shengyuan with the model number YJ-195, and carry out orientation pressing under the conditions of a magnetic field strength of 2.0T and a pressure of 8MPa, and finally obtain NdFeB Magnet compacts...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com