Complex Protection Element

A technology for protecting components and components, which is applied in the direction of electrical components, battery overvoltage protection, emergency protection devices, etc., and can solve problems such as inability to realize the protection circuit function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

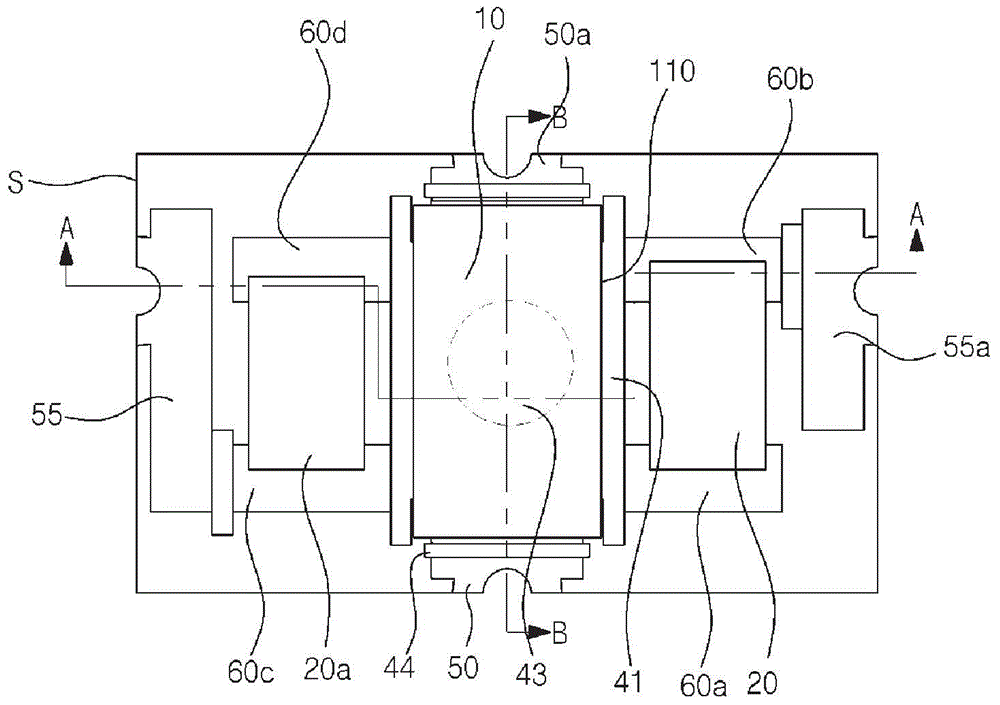

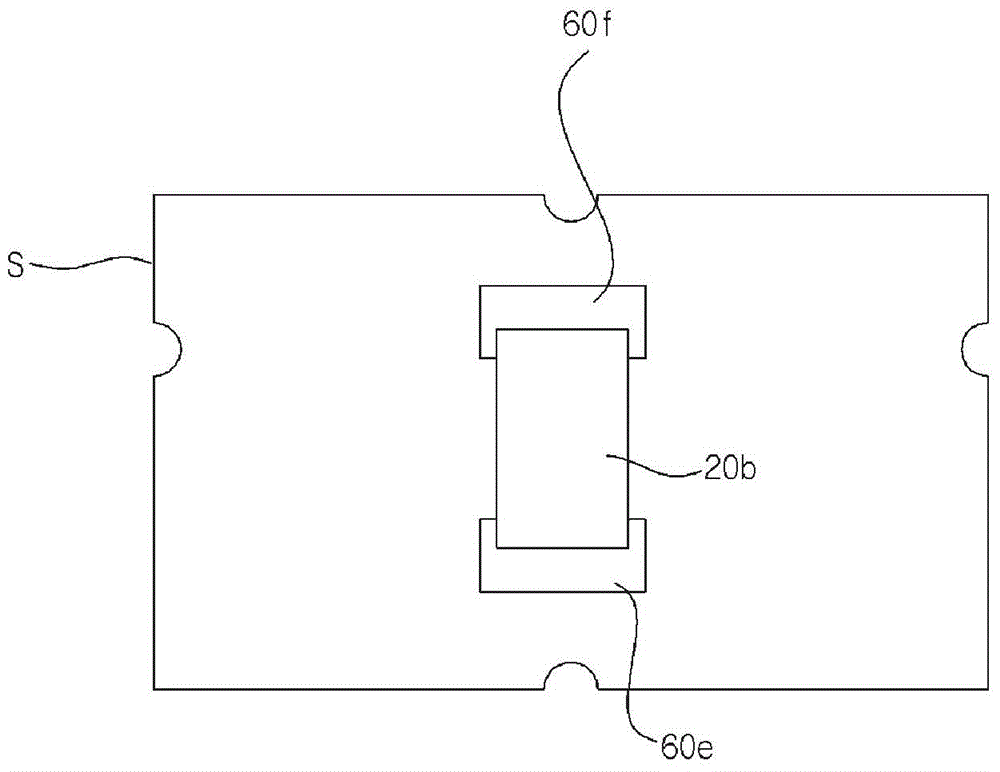

[0039] Embodiments of the present invention will be described in detail below with reference to the drawings.

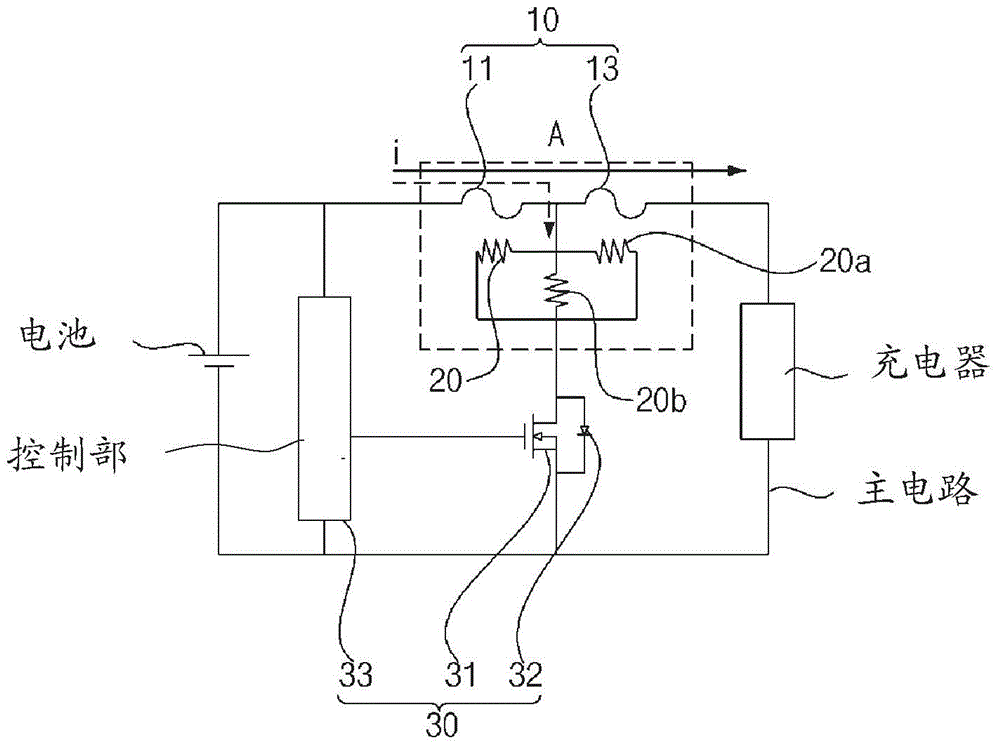

[0040] figure 1 It is a circuit diagram for explaining the use state of the composite protection element of this invention. refer to figure 1 , the composite protection element of the present invention protects the circuit and components connected to the main circuit under abnormal conditions by fusing the fusible element 10 connected to the main circuit.

[0041] The type of the main circuit to which the composite protection element of the present invention is applied is not particularly limited, and the main circuit may be a charging circuit for charging a battery.

[0042] On the above-mentioned main circuit, a battery (battery) and a charger (charger) are connected to the fusible element 10 . Specifically, the main circuit may include a plurality of resistance elements 20, 20a, 20b, and a switching element 30 connected to the plurality of resistance elements 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com