Orbital angular momentum plane spiral phase plate based on phase shift surface

An orbital angular momentum, helical phase plate technology, applied in waveguide-type devices, electrical components, circuits, etc., can solve the problems of large receiving end, large receiving radius, and high cost, and achieve small size, low cost, and light weight. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

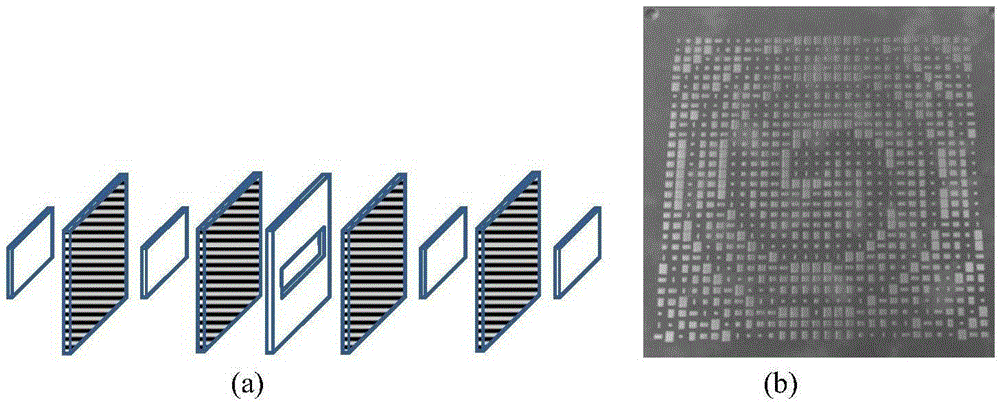

[0030] The planar phase shift unit structure designed in this patent, the working frequency is set at 60GHz, the side length of the unit is 2mm, and it includes four layers of media. figure 2 (a) is indicated by the slash texture, and the rest are 5 layers of metal layers. The middle metal layer is the size of the dielectric unit, and there is a slit in the center. The size of the slit will also affect the phase shift. Here, to ensure the phase shift and For loss requirements, the slit size is 1.5mm on the long side and 0.3mm wide; the patch layers are all the same size except the middle layer, and the phase shift amount is changed according to the patch size. Each patch of 8 different unit structures Dimensions are listed below. The overall structure contains a total of 30×30 unit structures.

[0031] Unit patch size

[0032]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com